Equipment and application for producing continuous fiber reinforced thermoplastic resin prepreg tape

A technology of reinforced thermoplastic and continuous fiber, which is applied in the production of equipment and application fields of continuous fiber reinforced thermoplastic resin prepreg tape, which can solve problems such as poor exhaust, affecting product quality, and tearing of prepreg tape, so as to avoid resin infiltration Poor, improve aesthetics, avoid tearing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

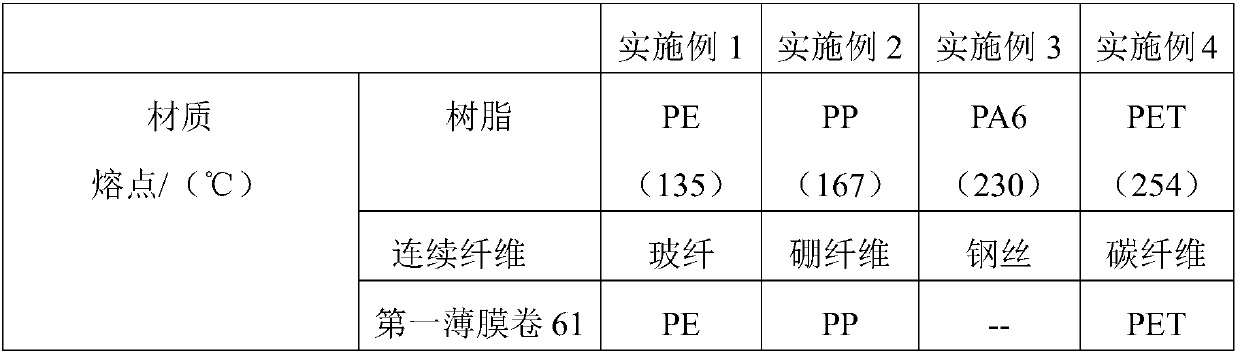

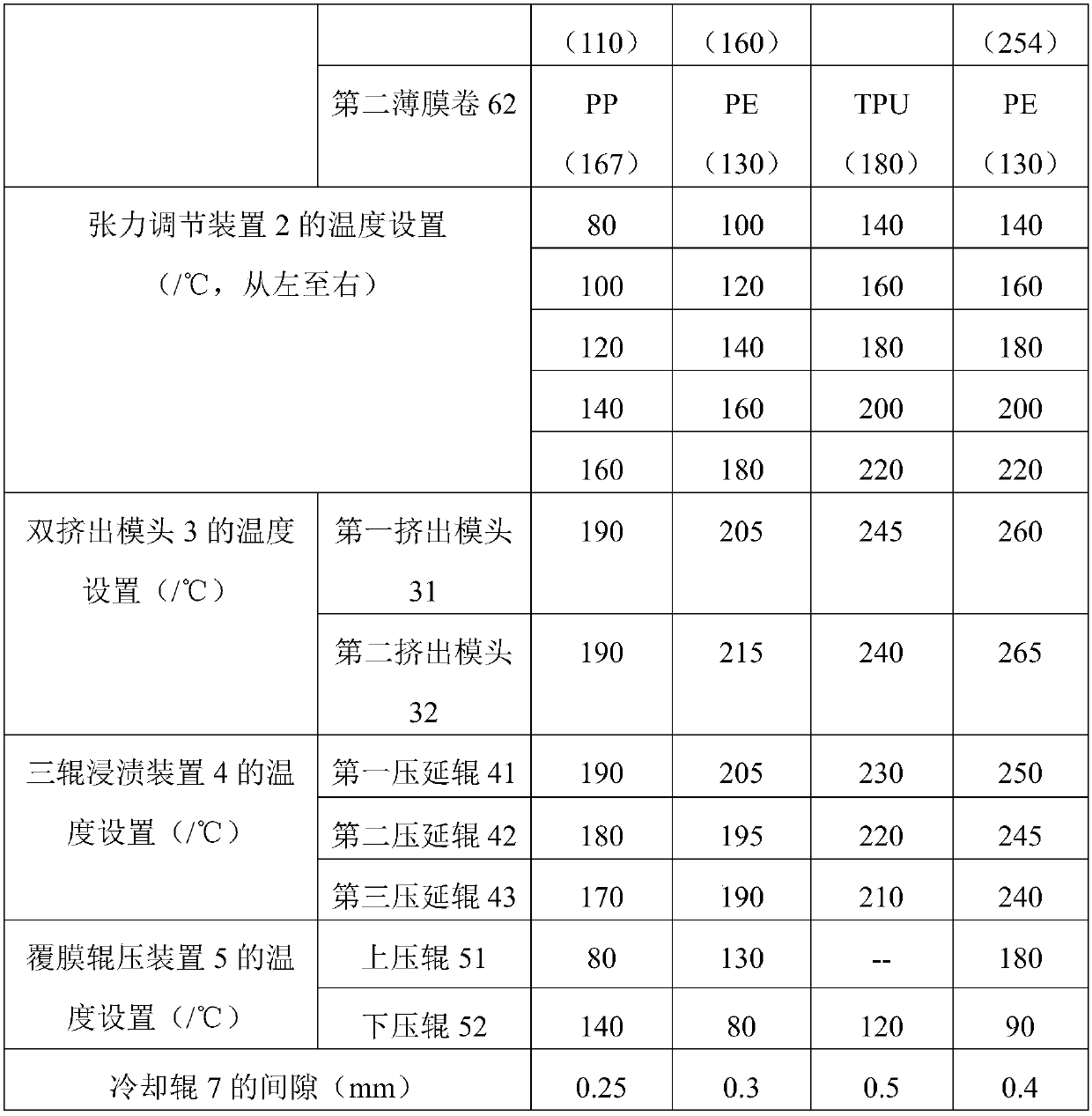

Embodiment 1~4

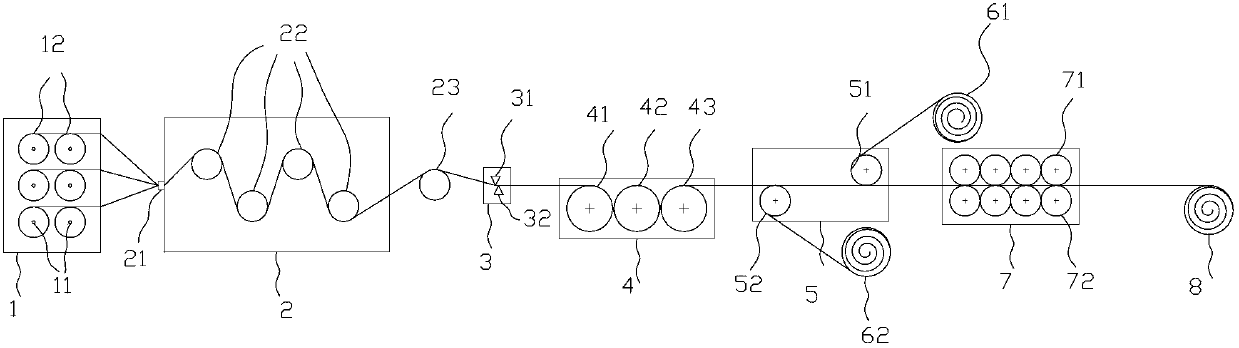

[0039] A method for producing continuous fiber-reinforced thermoplastic resin prepreg tape that can be coated online is as follows: After the continuous fiber is drawn from the creel 1, it is introduced into the double extrusion die 3 through the tension adjustment device 2; After the die head 3, the molten resin impregnates the continuous fiber, and then it is introduced into the three-roll impregnation device 4; the fully soaked prepreg tape product passes through the film rolling device 5, and the film coating process is completed simultaneously on the upper and lower sides; The final prepreg tape is introduced into the cooling rolling device 7; finally, it is wound and formed by the traction winding device 8, and the prepreg tape that is completely impregnated and coated on the surface can be obtained.

[0040] Such as figure 1 As shown, an equipment for producing continuous fiber-reinforced thermoplastic resin prepreg tape that can be coated online, the equipment includes...

Embodiment 5

[0063] A device for producing continuous fiber-reinforced thermoplastic resin prepreg tapes capable of film lamination on-line, such as figure 1 As shown, the equipment sequentially includes a creel 1, a tension adjustment device 2, a double extrusion die 3, a three-roll dipping device 4, a cooling rolling device 7 and a traction winding device 8, and the equipment also includes a coating rolling device 5. The first film roll 61 and the second film roll 62, the coating rolling device 5 is located between the three-roll dipping device 4 and the cooling rolling device 7, and the coating rolling device 5 is composed of staggered upper pressing rollers 51 and The lower pressure roller 52 is composed of the first film roll 61 and the second film roll 62 respectively arranged on the upper and lower sides of the film rolling device 5, and the upper and lower sides of the prepreg tape are covered by the first film roll 61 and the second film roll 62. The film is coated on the upper an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com