Bracket mounting device and bracket mounting method

A technology for installing devices and brackets, which is applied in the direction of workpiece clamping devices and manufacturing tools, which can solve the problems of large energy consumption, failure to clean the adhesive glue, and affect the appearance of the product, so as to avoid the effect of outflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention are described in detail below:

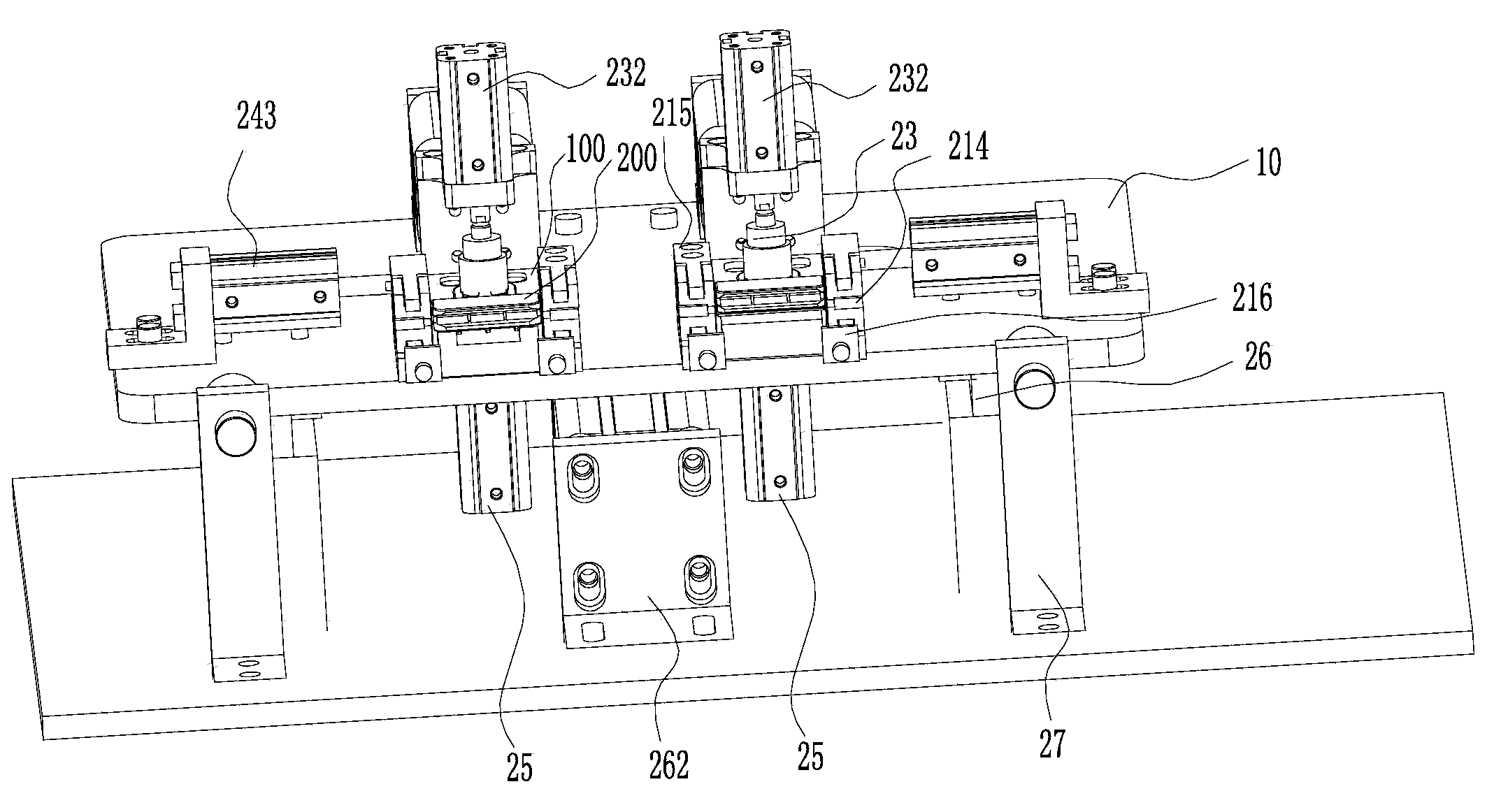

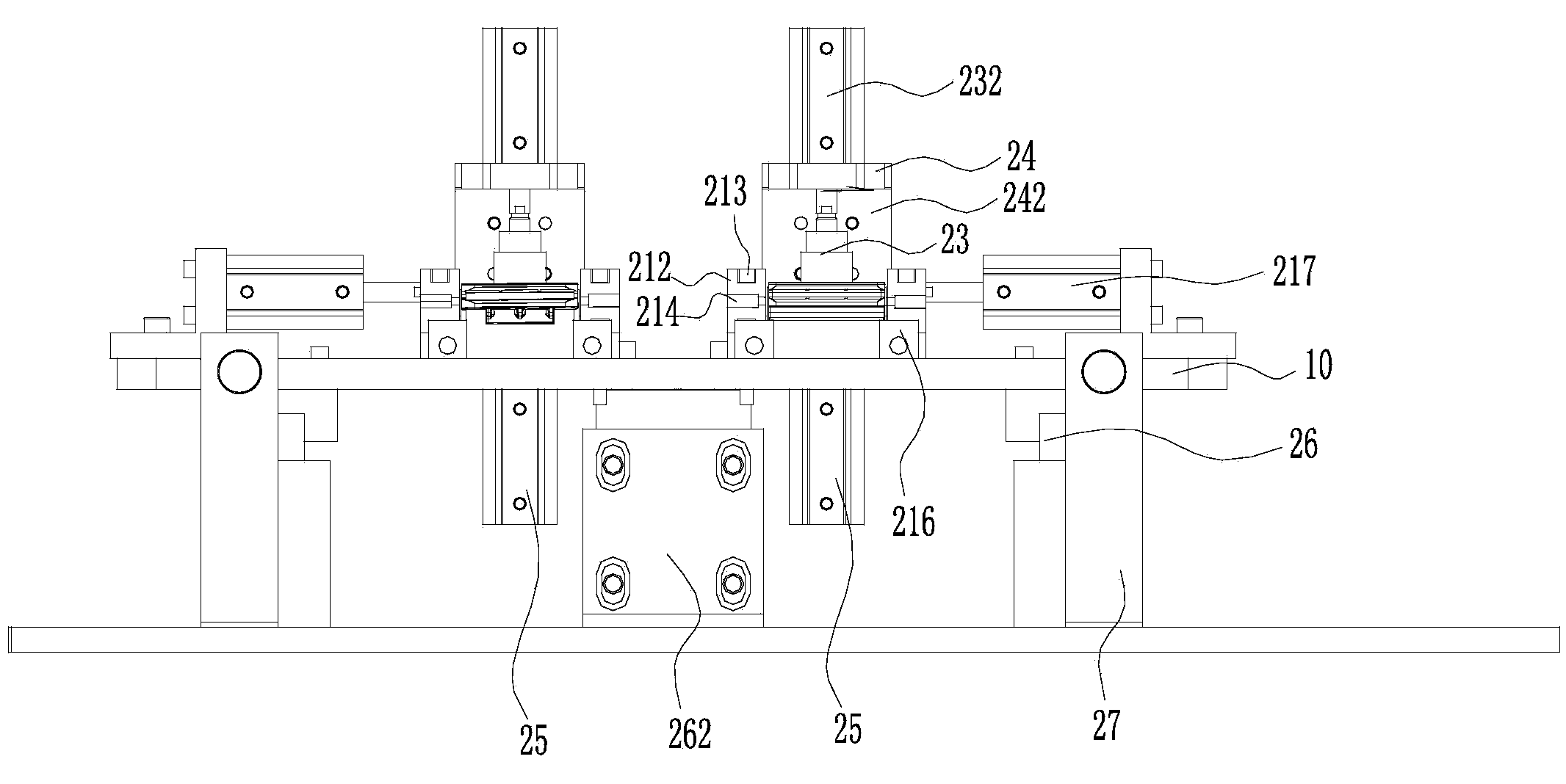

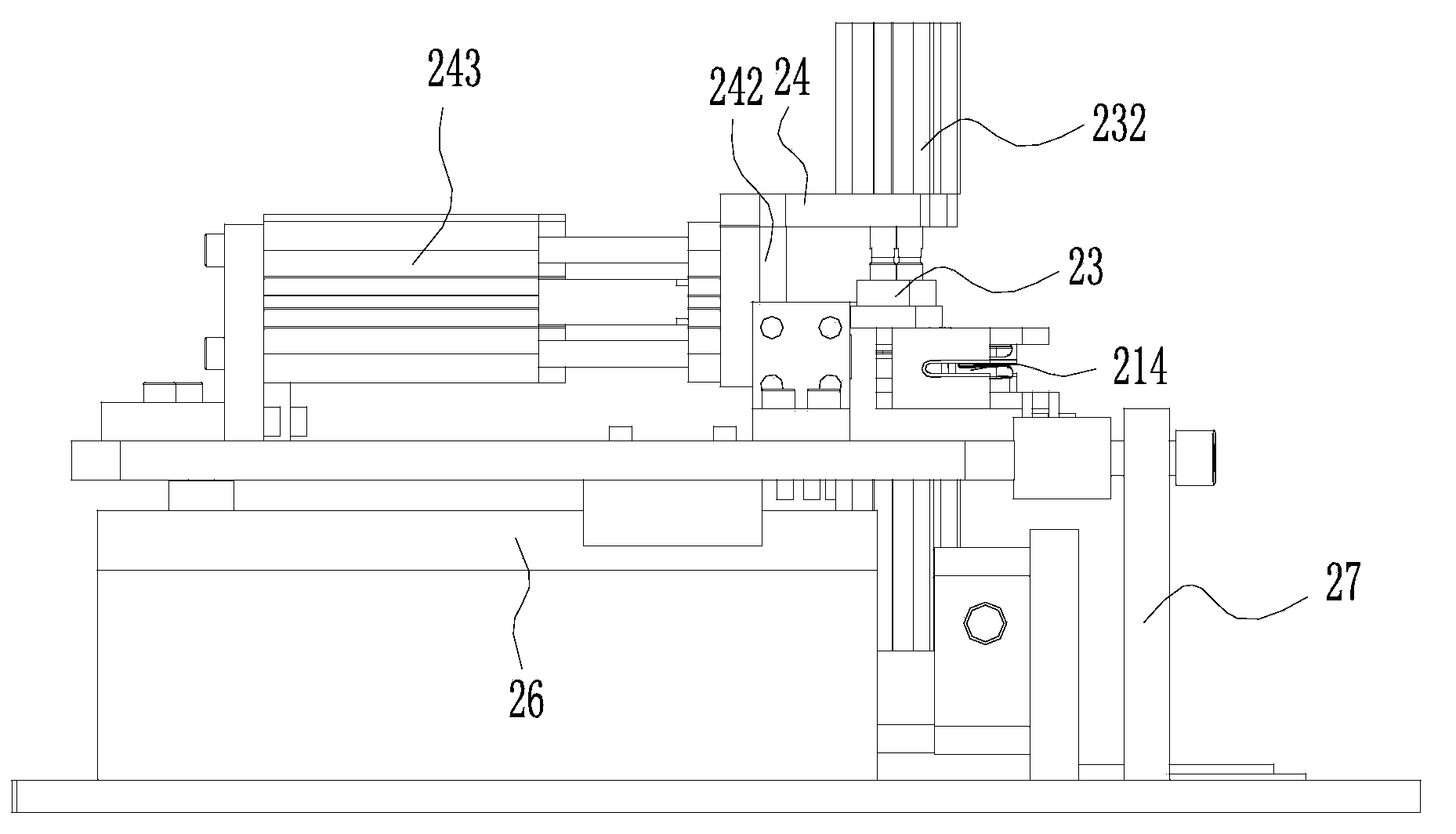

[0032] Such as figure 1 As shown, a bracket installation device includes a mounting table 10, a bracket 100 placed on the mounting table 10, and a positioning mechanism for positioning the bracket 200 on the bracket groove 100, located in the bracket groove 100 Above and can move vertically close to the upper pressing mechanism of the bracket 200 or away from the bracket 200, the first clamping mechanism 21 and the second clamping mechanism 22 located on the two opposite sides of the bracket 200, the first clamping mechanism 21 can move laterally to make the bracket groove 100 resist against the second clamping mechanism 22 , and also includes a pushing mechanism that drives the installation platform 10 to move longitudinally. Wherein, the second clamping mechanism 22 can also be moved laterally, so that the second clamping mechanism 22 cooperates with the first clamping mechanism 21 to clamp the bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com