Angle-adjustable polisher

A polishing machine and adjustable technology, applied in the field of polishing machines, can solve the problems of inability to realize large-scale application, high manufacturing cost, inconvenient operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

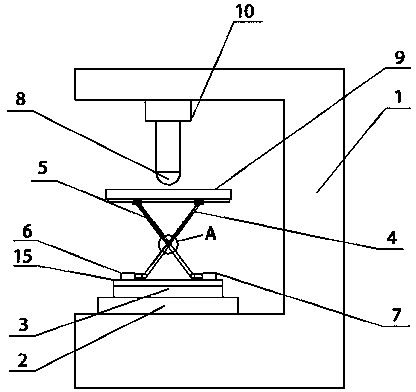

[0015] like figure 1 and figure 2 A polishing machine with an adjustable angle is shown, and its structure includes a fuselage 1, a polishing device connected to the top of the fuselage 1, and a workbench 9; the fuselage 1 is also provided with an omnidirectional transmission device, which An angle adjustment device is arranged on the top, and the angle adjustment device is movably connected with the workbench 9. The polishing device is composed of a rotating motor 10 and a grinding head 8 fixedly connected, and the rotating motor 10 is connected to the top of the fuselage 1 . During operation, the workpiece to be processed is fixedly connected to the workbench 9, and the omnidirectional transmission device is controlled by the controller to transfer the material to the bottom of the polishing device, and then the angle of the workbench 9 is adjusted by the angle adjustment device to make the workpiece to be processed The surface is in contact with the grinding head 8, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com