Device for machining thin-walled gear ring broaching

A thin-walled ring gear, to-be-processed technology, used in broaching device, positioning device, metal processing, etc., can solve the problems of uncontrollable heat treatment deformation of parts, plastic deformation of thin-walled ring gear, large deformation, etc., and achieve convenient heat treatment process. , Control the force deformation and taper of broaching, and the effect of convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

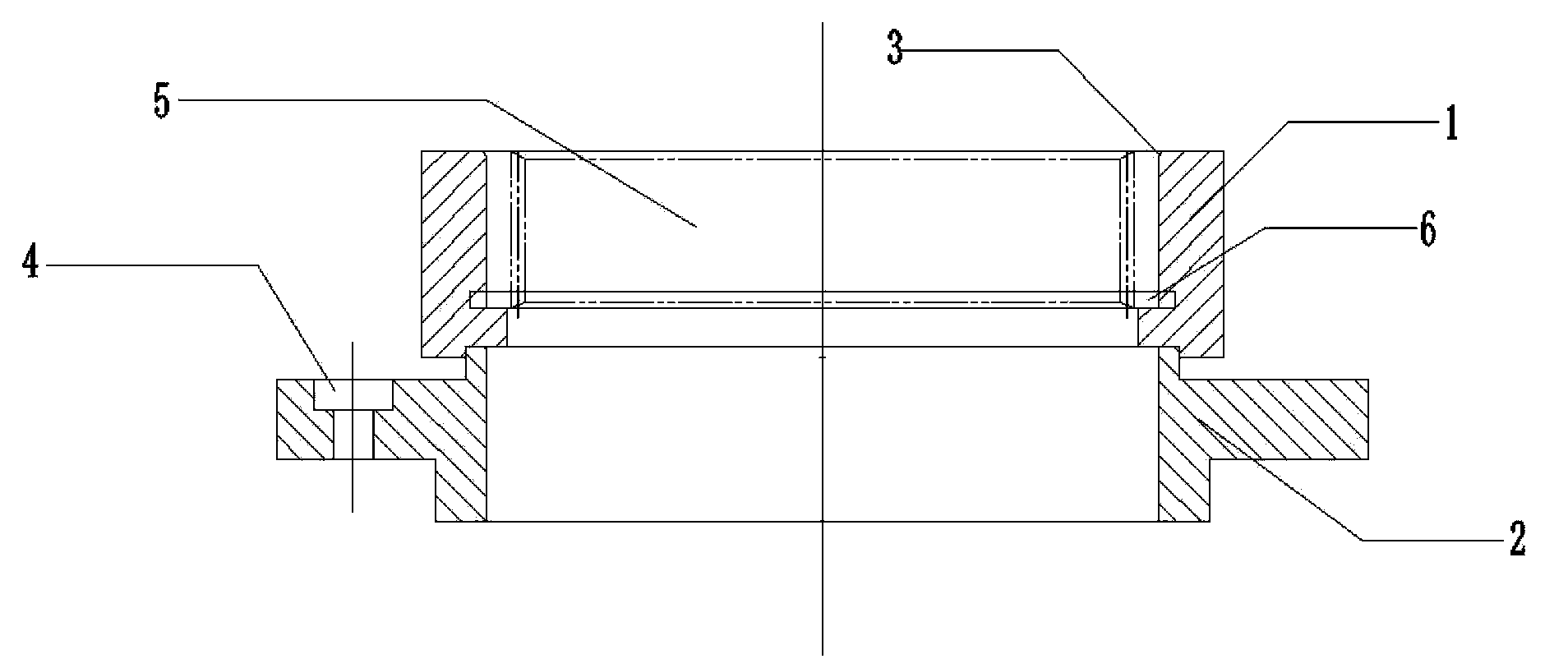

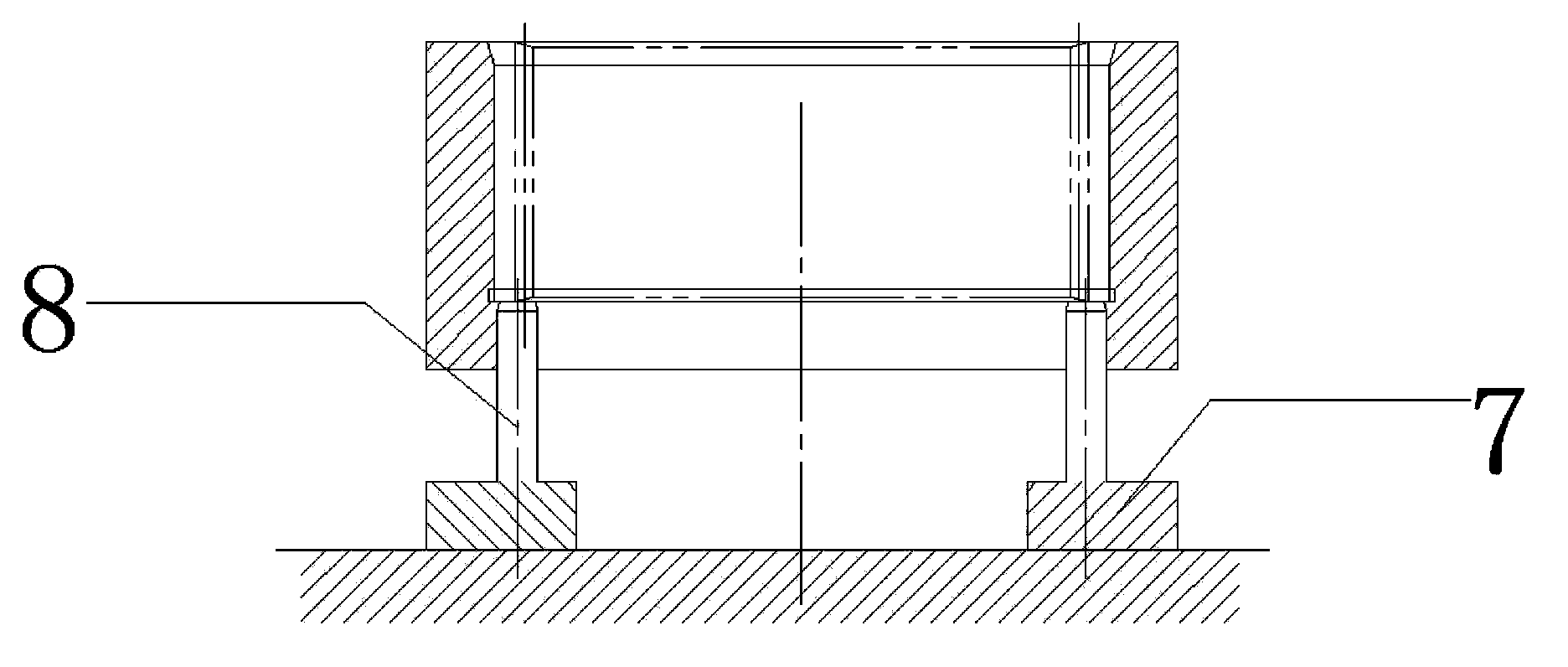

[0016] Such as figure 1 with figure 2 As shown, the present invention includes a thin-walled ring gear fixing part, which is a cylindrical structure, and an upper groove is arranged in the cylindrical structure, and the size of the upper groove and the thin-walled ring gear to be processed The size of the ring gear is the same, but the depth is greater than the thickness of the thin-walled ring gear. This design purpose is to prevent the M value of the tool end from getting out of control. At the same time, it can also precisely control the matching size between the outer circle of the part and the inner hole of the tooling. In addition, there are chamfers on both sides of the top of the upper groove. The purpose of the chamfers is to better position and place the thin-walled ring gear to be processed. In addition, there is a groove inside the bottom of the upper groove. The purpose of the groove is to make the placement of the workpiece into the fixture more precisely cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com