Soldering iron

A technology for soldering irons and welding heads, which is applied in the direction of soldering irons, welding equipment, welding equipment, etc., can solve problems such as irregular operation results, and achieve the effects of reducing manufacturing costs, easy assembly, and reducing size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

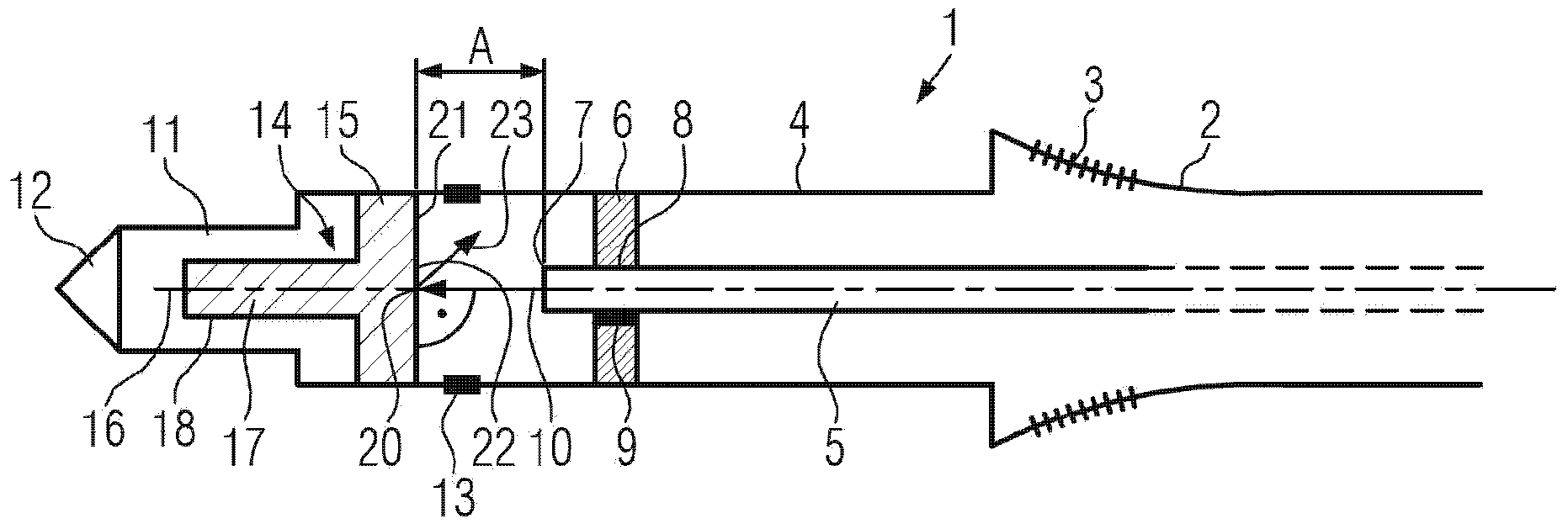

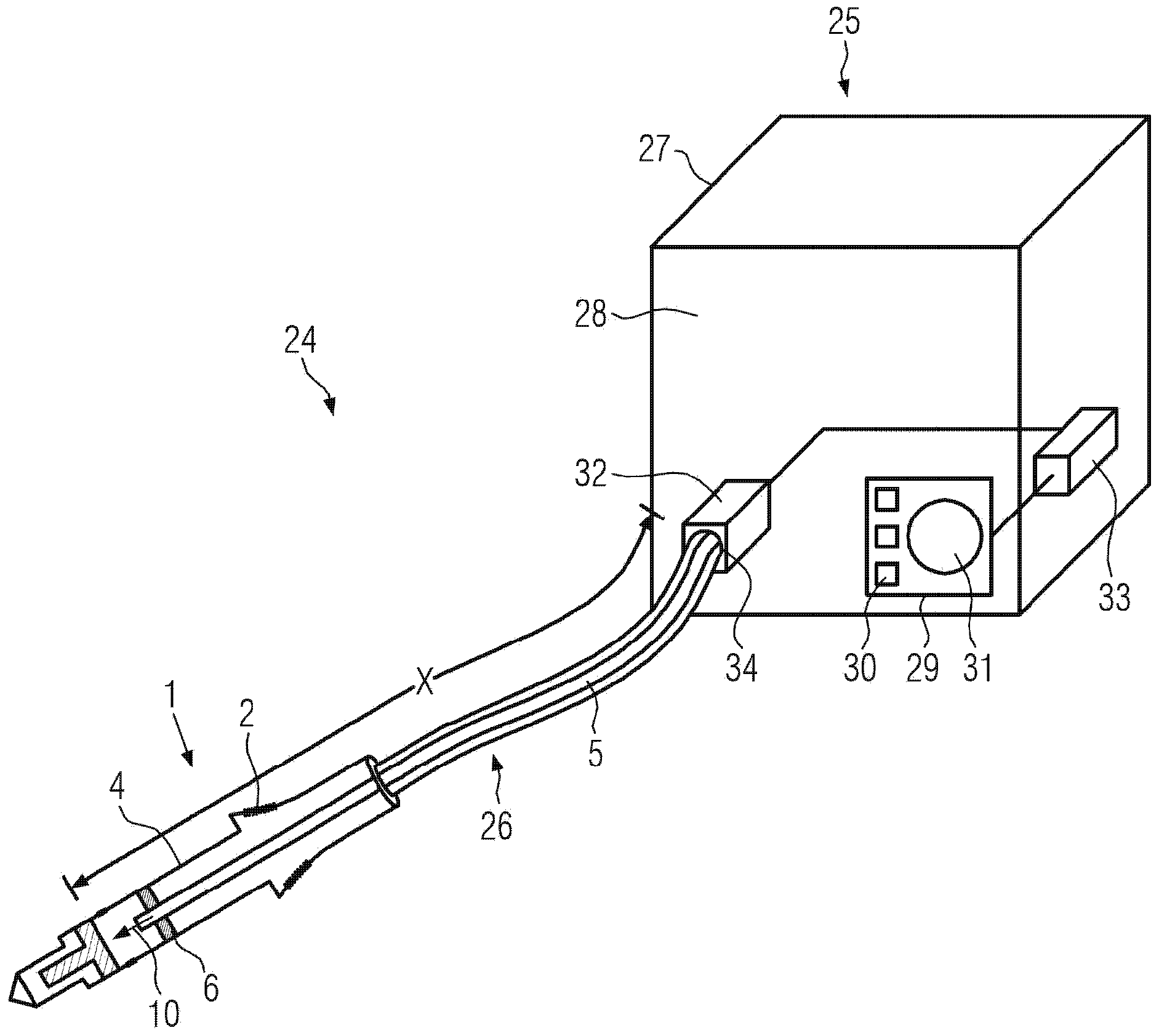

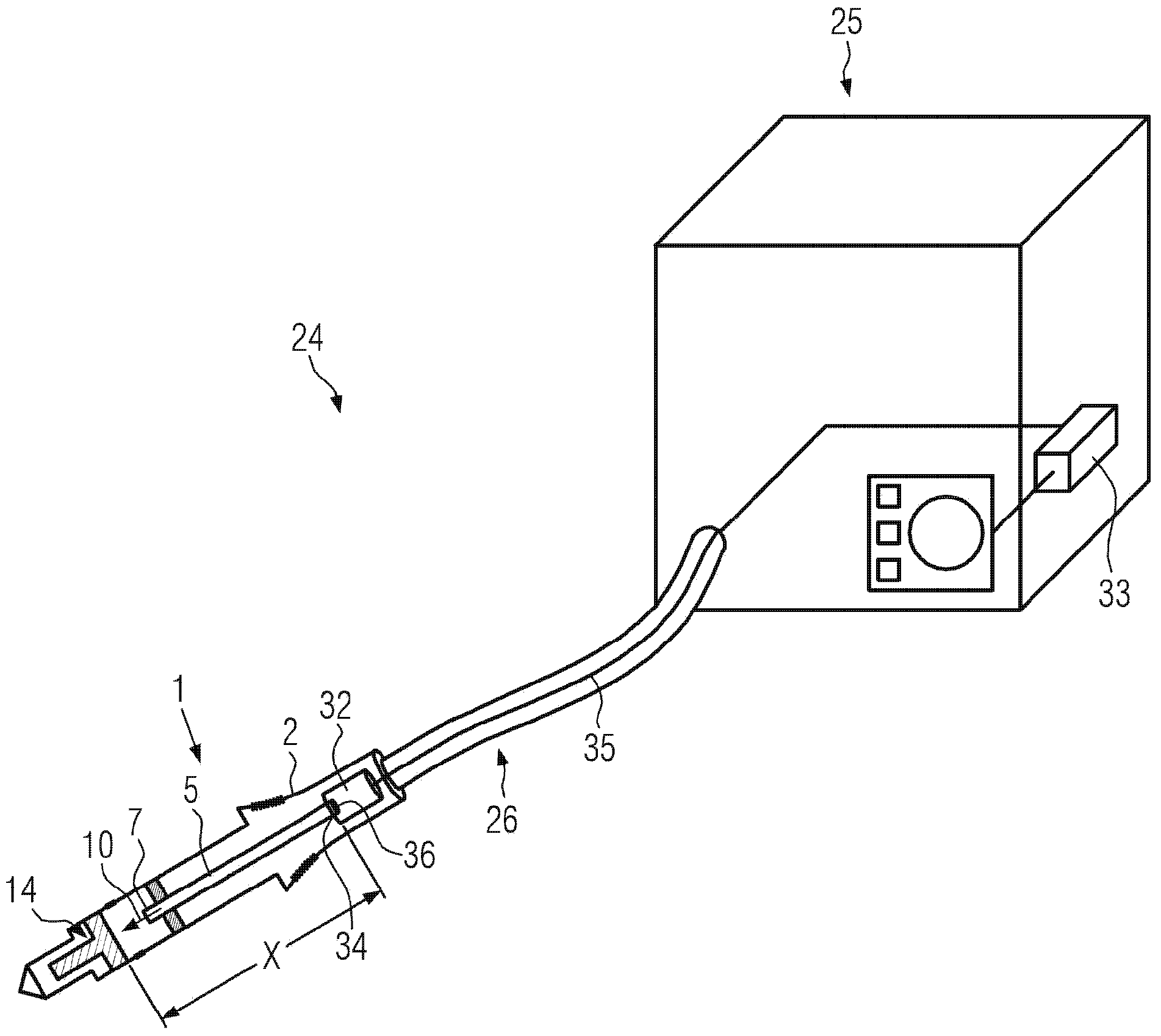

[0065] figure 1 A soldering iron 1 according to an embodiment of the present invention is shown. In order to better illustrate the features according to the invention, the soldering iron 1 is shown in cross-sectional view. The soldering iron 1 includes a handle 2 . The user is able to hold the soldering iron 1 at the handle 2 in order to safely guide the soldering iron 1 for machining workpieces, for example to form welds between the workpieces to be processed. The handle 2 can be produced from a plastic material that is more grippable for the user. In particular, the handle 2 may comprise a recessed area 3, preferably at the location where the user applies a finger. By virtue of the recessed area 3, the user's hand can be prevented from slipping off the handle 2. The recessed area 3 can also be replaced or supplemented by an anti-slip material, such as a rubber coating.

[0066] The soldering iron 1 also includes a head portion 4 . The head portion 4 is fixed to the han...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com