Powerful vacuum chuck

A vacuum suction cup, powerful technology, applied in the direction of suction cups, turning equipment, connecting components, etc., can solve the problems of not meeting the requirements of the workpiece, and achieve the effect of high degree of automation, simple structure, and enhanced suction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

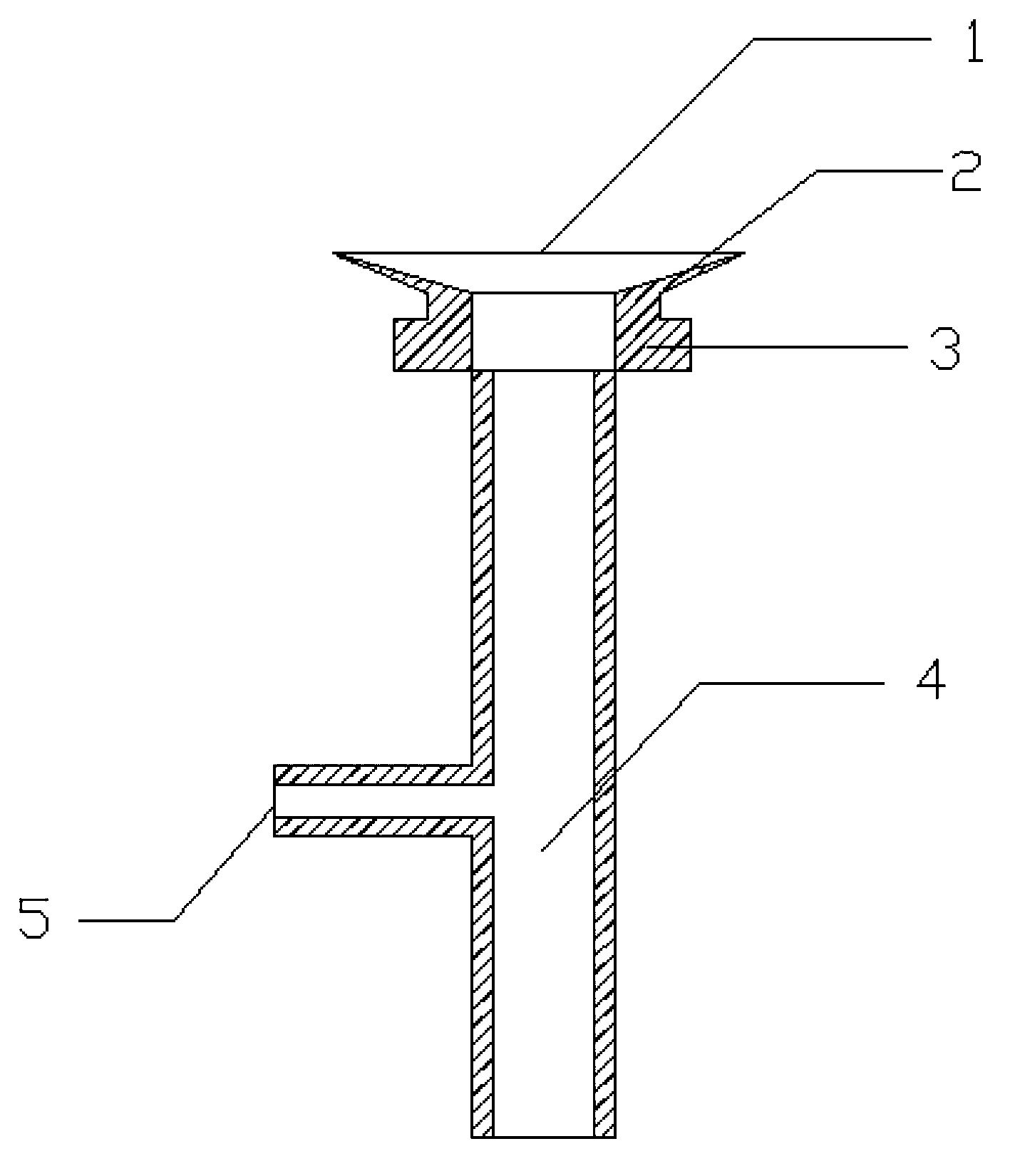

[0012] Such as figure 1 Shown, the present invention is a kind of powerful vacuum suction cup, and the sucker of this powerful vacuum suction cup is the annular circle body of rubber material, and the wall of annular circle body upper half 2 is thinner than the wall of lower half 3, and upper half 2 The inner diameter of the upper half is larger than the inner diameter of the lower half 3, and the inner diameter of the upper half 2 gradually increases from bottom to top.

[0013] In practical application, the inner diameter of the upper half 2 of the annular ring body is larger, which is more conducive to uniform suction around the suction cup. The wall of the lower half 3 of the annular ring body is thicker and not easily deformed, which is convenient for firmly adsorbing the vacuum suction cup 1 on the suction cup seat. The quick connector 5 is connected with the vacuuming device, and when vacuuming, the suction force of the suction cup is stronger.

[0014] The working pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com