High-accuracy numerical-control roundness correction machine

A high-precision, rounding technology, used in the field of rolling machines, can solve the problems of reducing precision, increasing the gap, unable to keep the gap between the work rolls stable, etc., and achieving the effect of improving the rounding accuracy and the force balance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

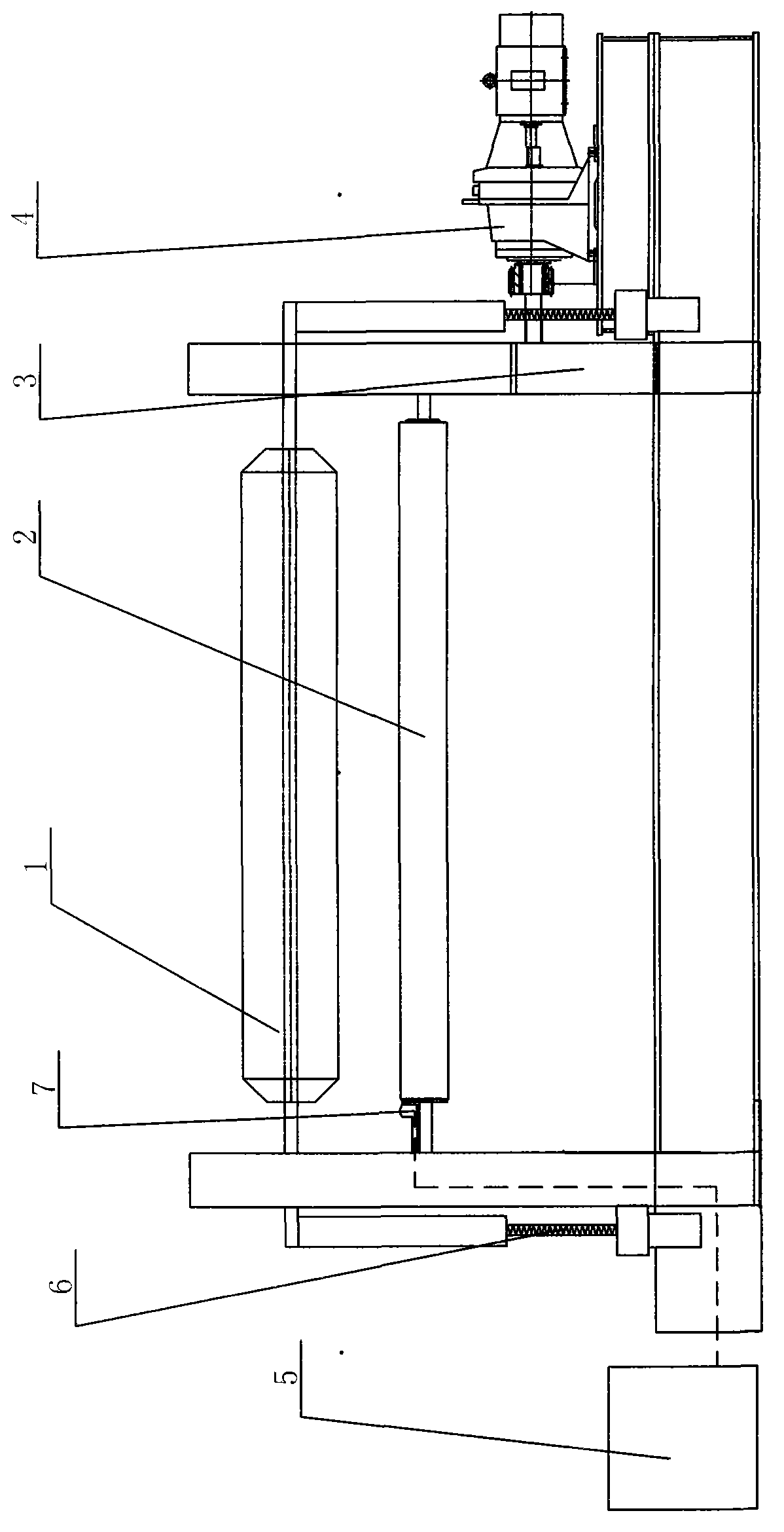

[0012] see figure 1 , the specific embodiment adopts the following technical scheme: it comprises upper roll 1, lower roll 2, lower roll drive mechanism 3, lower roll drive mechanism 4, PLC controller 5, and it also comprises lead screw drive mechanism 6 and displacement sensor 7 ; Both sides of the upper roller 1 are respectively connected with the screw transmission mechanism 6, and one side of the lower roller 2 is provided with a displacement sensor 7, and the displacement sensor 7 is connected with the PLC controller 5.

[0013] This specific implementation method adopts the following process: it divides the rounding process into N passes. First, the lower roller 2 of each pass drives the forward and reverse rotation of the workpiece for 1-2 weeks. The upper roller 1 and the two lower rollers 2 The distance between the center lines gradually decreases according to 1-N passes, and then gradually increases according to N-1. The residual stress in the workpiece goes through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com