A kind of chloropropanol production device and the method for using it to produce chloropropanol

A production device and technology for chloropropanol, which are applied in chemical methods, chemical instruments and methods, and organic chemistry for reacting liquids and gaseous media, and can solve the problem that chloropropanol production equipment needs to be improved and increase civil construction investment and equipment investment. , the large area of the reaction tower, etc., to achieve the effect of reducing the amount of exhaust gas, reducing the difficulty of processing, and reducing the volume of the reactor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

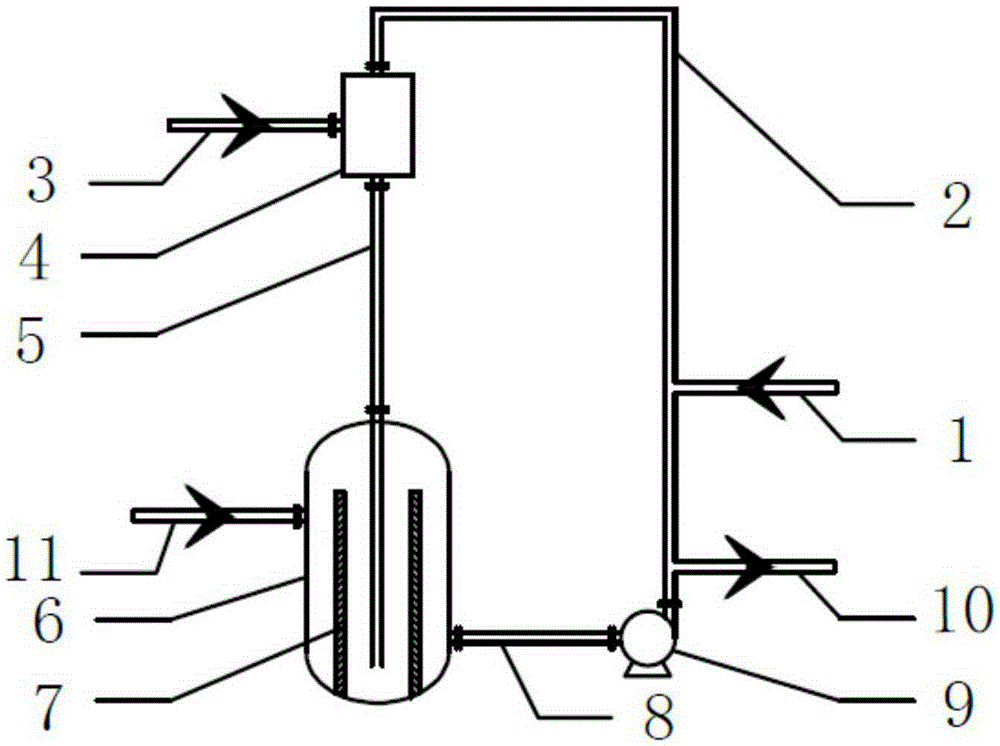

[0036] A chloropropanol production device, comprising raw material chlorine gas feed pipeline 1, chlorine gas dissolution pipeline 2, propylene feed pipeline 3, propylene injector 4, propylene hypochlorous acid mixing pipeline 5, chloropropanol output pipeline 8, liquid flow pump 9. Chloropropanol discharge pipeline 10, raw water feed pipeline 11, characterized in that it also includes a bubble reactor 6 and an inner sleeve 7, wherein the upper end of the inner sleeve 7 is vertically fixed to the bubble reactor 6 inside, the bottom of the inner sleeve 7 is sealed and connected to the bottom inner wall of the bubble reactor 6, one end of the chlorine gas dissolving pipeline 2 is connected to the chlorine gas feed line 1, the other end is connected to the propylene injector 4, and one end of the propylene feed line 3 is connected to the The propylene injector 4 is connected, one end of the propylene hypochlorous acid mixing pipeline 5 is connected with the propylene injector 4, a...

Embodiment 2

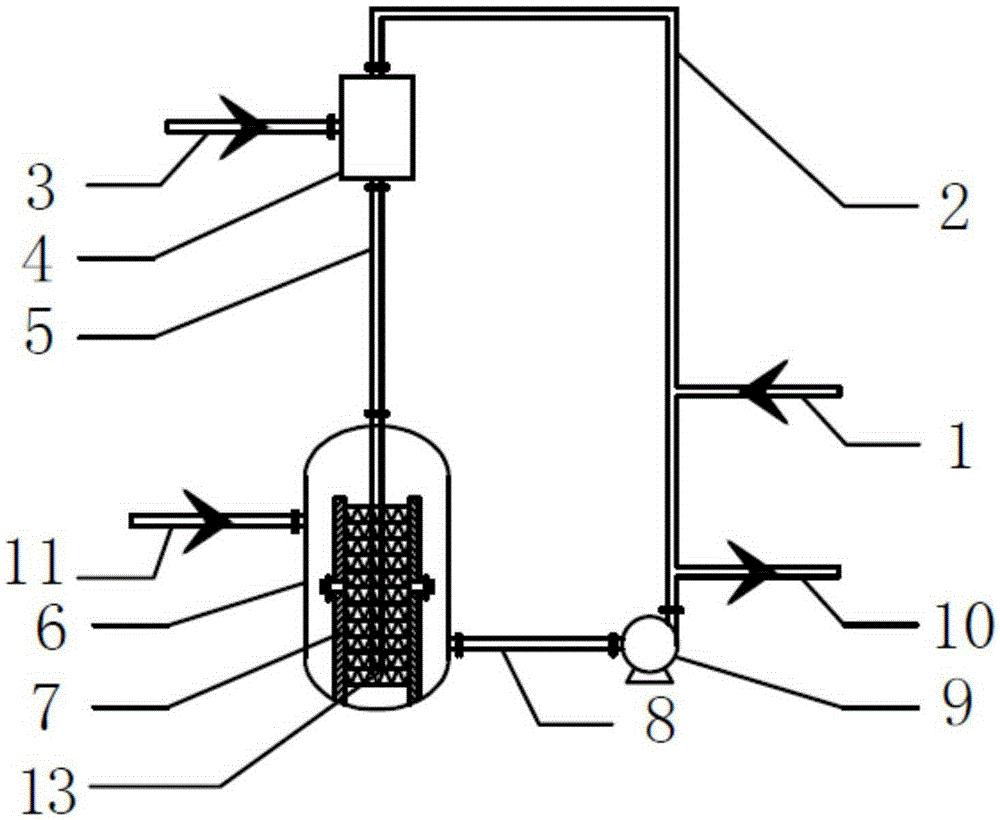

[0045]A chloropropanol production device, comprising raw material chlorine gas feed pipeline 1, chlorine gas dissolution pipeline 2, propylene feed pipeline 3, propylene injector 4, propylene hypochlorous acid mixing pipeline 5, chloropropanol output pipeline 8, liquid flow pump 9. Chloropropanol discharge pipeline 10, raw water feed pipeline 11, characterized in that it also includes a bubble reactor 6 and an inner sleeve 7, wherein the upper end of the inner sleeve 7 is vertically fixed to the bubble reactor 6 inside, the bottom of the inner sleeve 7 is sealed and connected to the bottom inner wall of the bubble reactor 6, one end of the chlorine gas dissolving pipeline 2 is connected to the chlorine gas feed line 1, the other end is connected to the propylene injector 4, and one end of the propylene feed line 3 is connected to the The propylene injector 4 is connected, one end of the propylene hypochlorous acid mixing pipeline 5 is connected with the propylene injector 4, an...

Embodiment 3

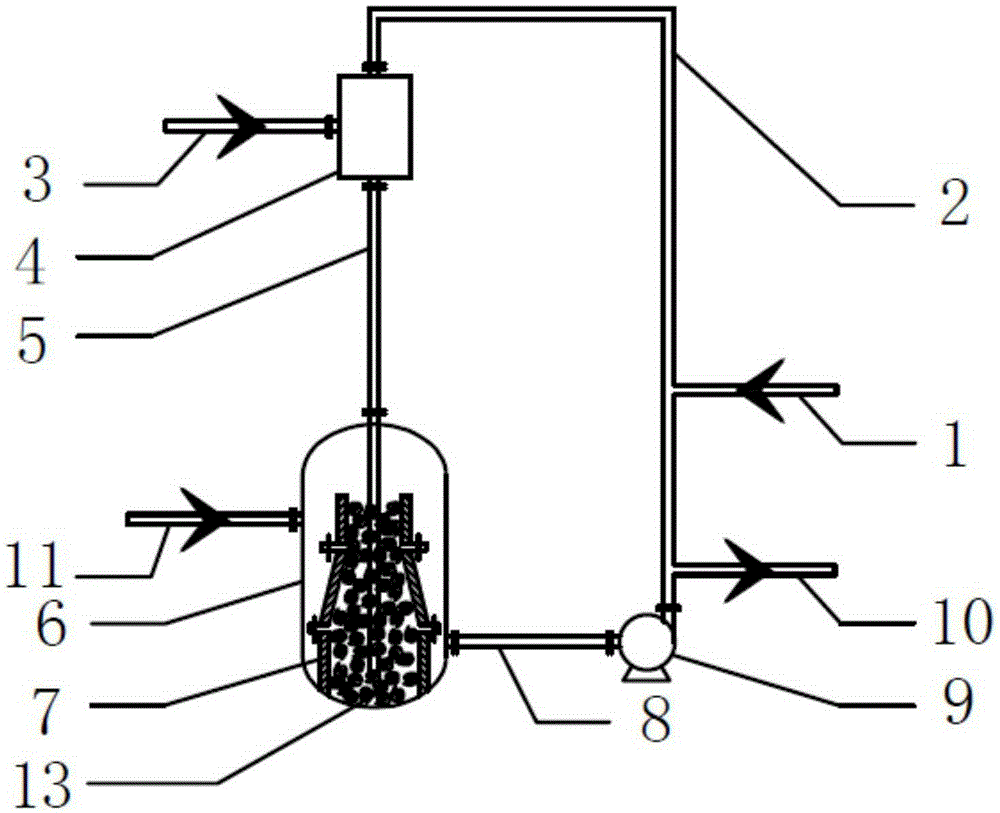

[0054] A chloropropanol production device, comprising raw material chlorine gas feed pipeline 1, chlorine gas dissolution pipeline 2, propylene feed pipeline 3, propylene injector 4, propylene hypochlorous acid mixing pipeline 5, chloropropanol output pipeline 8, liquid flow pump 9. Chloropropanol discharge pipeline 10, raw water feed pipeline 11, characterized in that it also includes a bubble reactor 6 and an inner sleeve 7, wherein the upper end of the inner sleeve 7 is vertically fixed to the bubble reactor 6 inside, the bottom of the inner sleeve 7 is sealed and connected to the bottom inner wall of the bubble reactor 6, one end of the chlorine gas dissolving pipeline 2 is connected to the chlorine gas feed line 1, the other end is connected to the propylene injector 4, and one end of the propylene feed line 3 is connected to the The propylene injector 4 is connected, one end of the propylene hypochlorous acid mixing pipeline 5 is connected with the propylene injector 4, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com