A rubber belt filter

A rubber belt and filter technology, applied in the direction of filtration separation, mobile filter element filter, separation method, etc., can solve the problems of easy fouling and blockage, easy crystallization, fouling, and inability to filter in the vacuum suction filter box, so as to avoid Material crystallization and filtrate scaling, not easy to scale, reduce maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

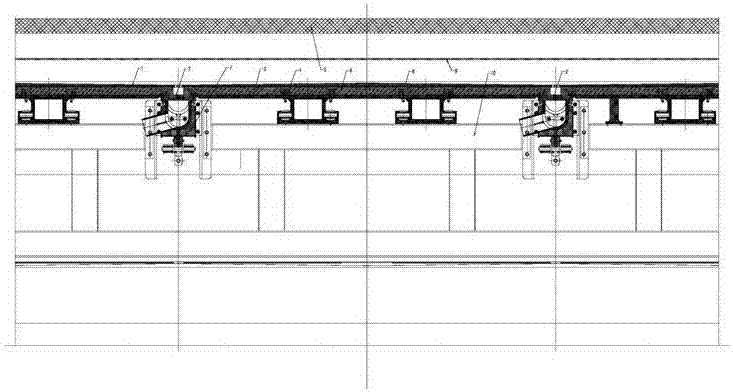

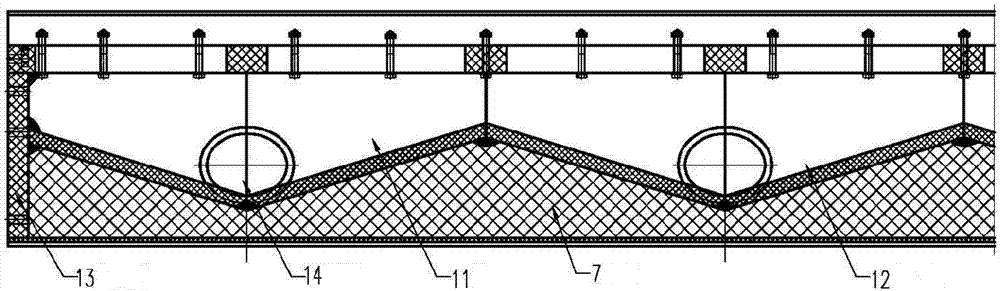

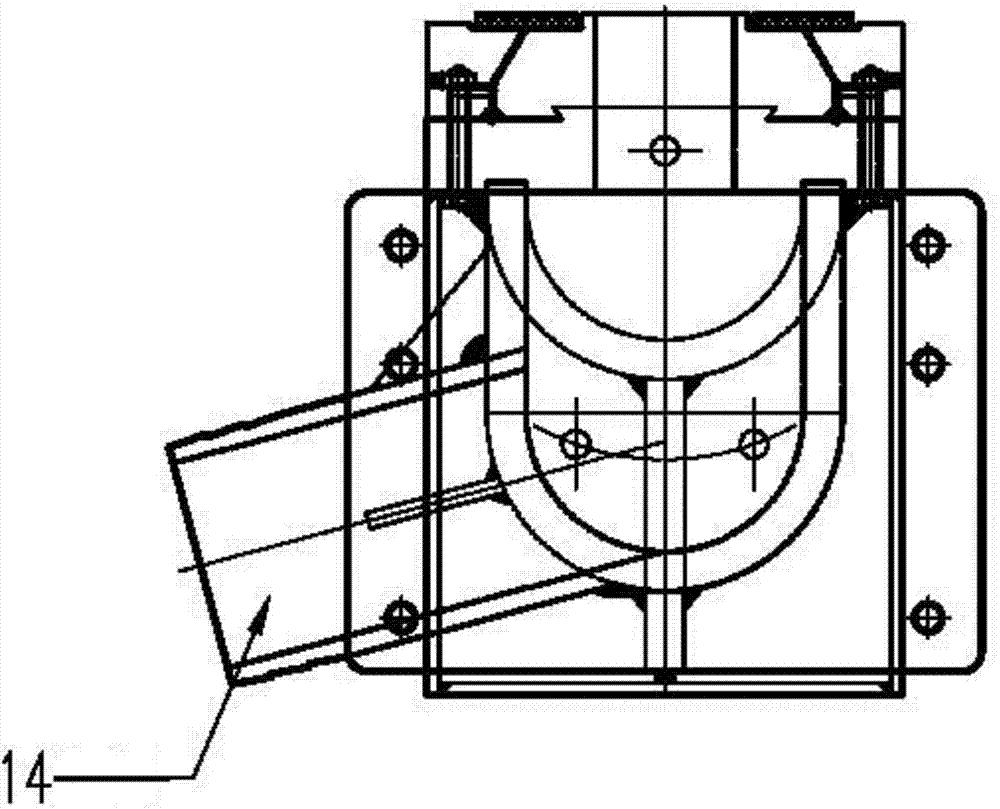

[0030] In this embodiment, the rubber belt filter is taken as an example, as Figure 1 to Figure 3 As shown, the rubber belt filter provided by the embodiment of the present invention includes: rubber belt 1, vacuum filter box 2, supporting plate 3, support seat 4, heat preservation cover 5, heat preservation water 6, heat preservation cotton 7, wear-resistant belt 8 , filter cloth 9, bracket 10, diversion tank 11, filtrate conduit 12, connecting flange 13, liquid outlet 14. The supporting plate 3 is installed horizontally through the vertical column on the support 10, and the supporting base 4 is installed vertically at intervals on the supporting plate 3. The insulating water 6 is filled between the supporting plate 3 and the supporting base 4, and the rubber belt 1 passes through the supporting base 4 and the insulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com