Manufacturing method for rain-tight seam structure of umbrella

A manufacturing method and umbrella technology, which can be applied to walking sticks and other directions, can solve problems such as rain leakage, and achieve the effects of good anti-rain leakage function, good social value, and strong practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

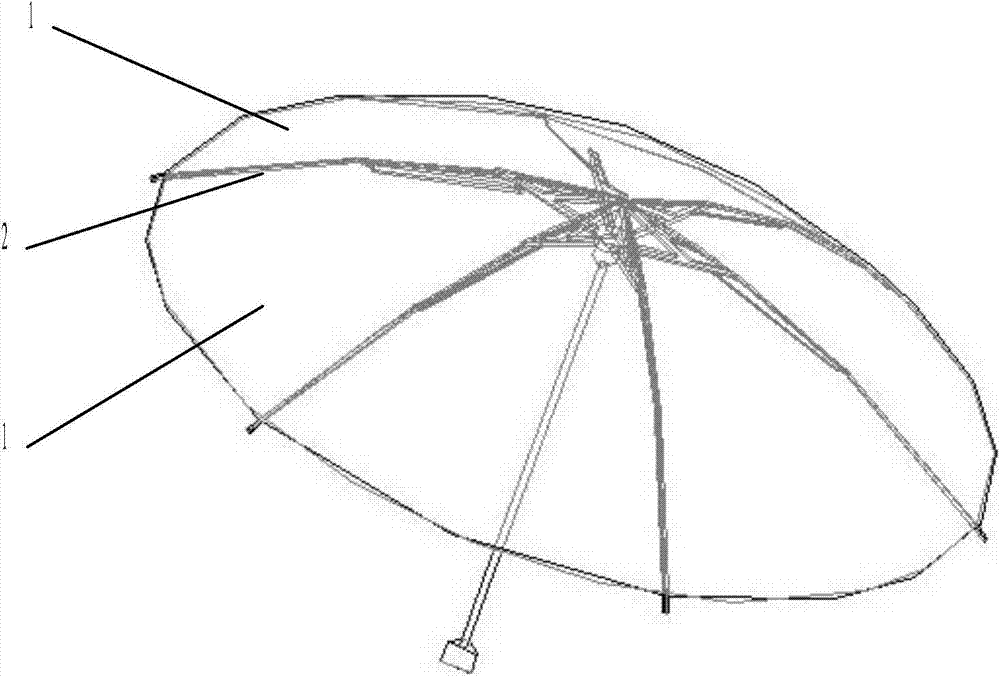

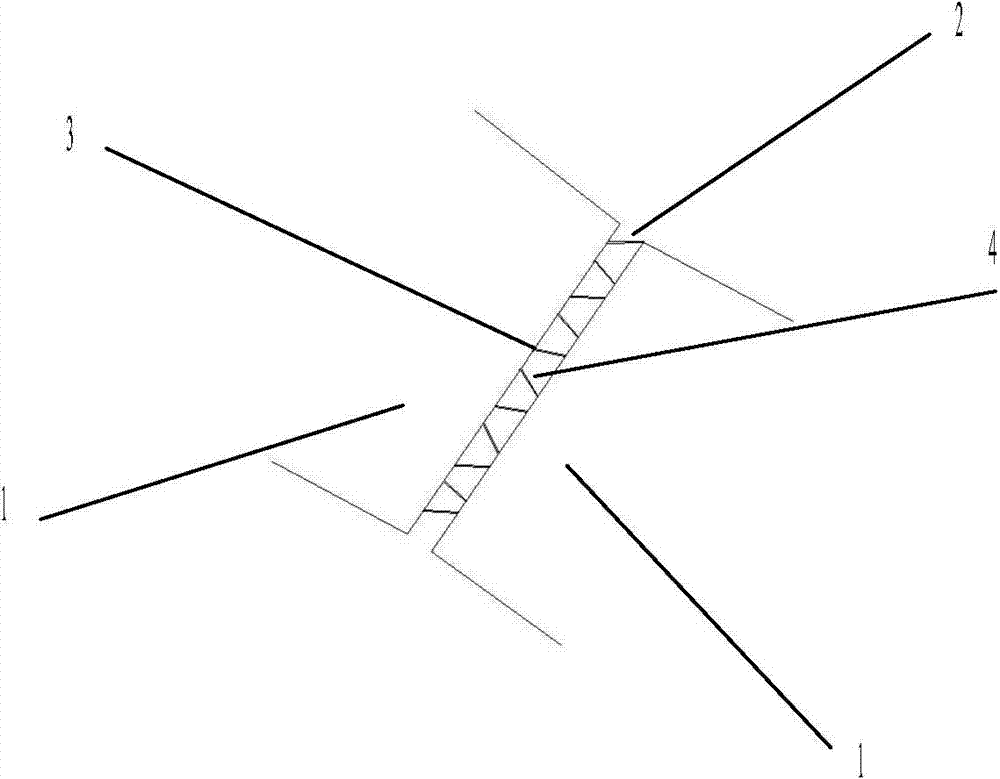

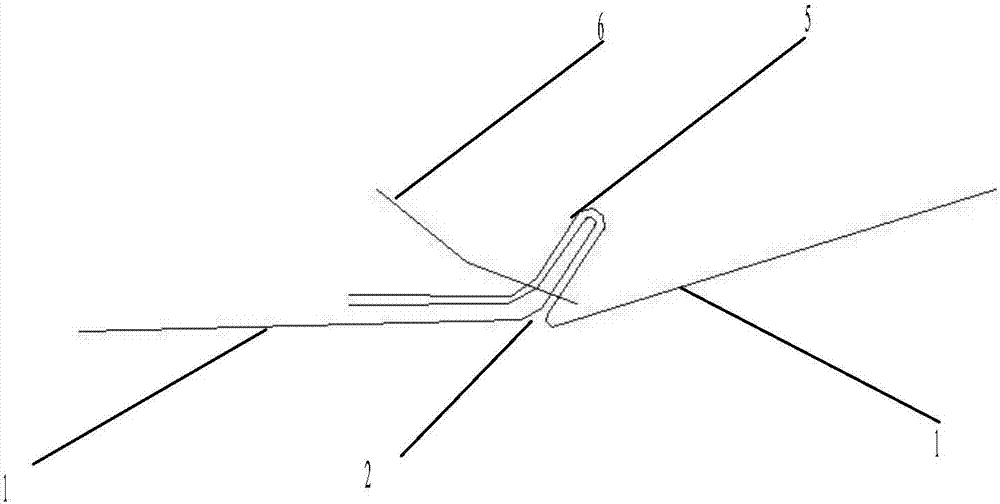

[0027] Such as figure 1 with figure 2 As shown, the umbrella surface of an umbrella is formed into a spherical structure or a parabolic structure by stitching together more than four triangular umbrella fabrics 1 and triangular umbrella fabrics 1 with thread 6. The shapes and sizes of all triangular umbrella fabrics 1 Exactly the same, the present invention uses six triangular umbrella cloth 1. combine image 3 , the manufacturing method of the rain-tight seam structure of umbrella is: at first, the seams of adjacent two triangular umbrella cloths 1 and triangular umbrella cloth 1 of the umbrel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com