Back sheet for solar cells, and solar cell using same

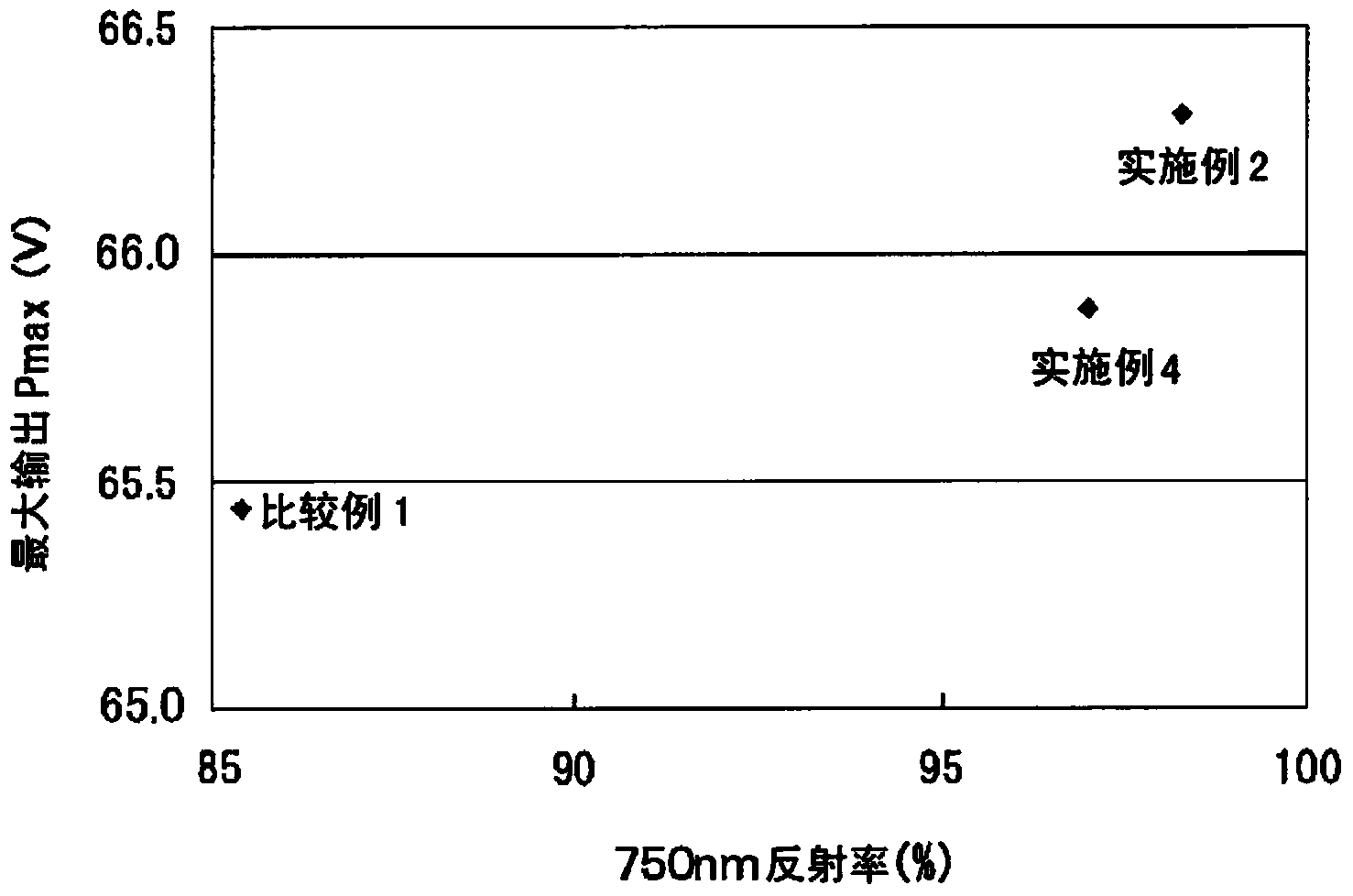

A solar cell and backplane technology, applied in applications, circuits, electronic equipment, etc., can solve the problems of expensive and weak mechanical strength of fluorine-based resin films, and achieve stable performance, high cost reduction effect, and excellent light reflectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1、2、6、10、11

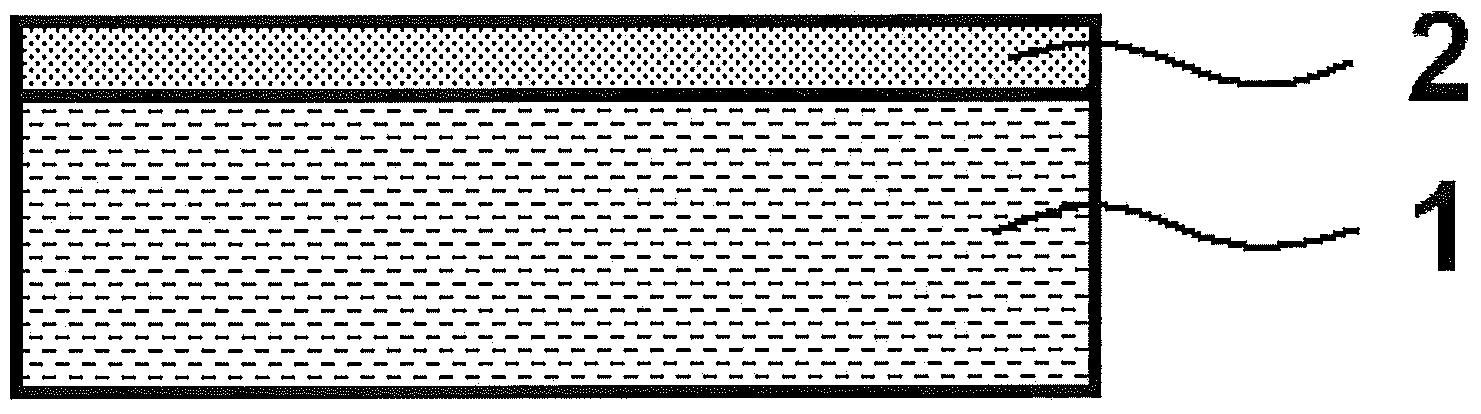

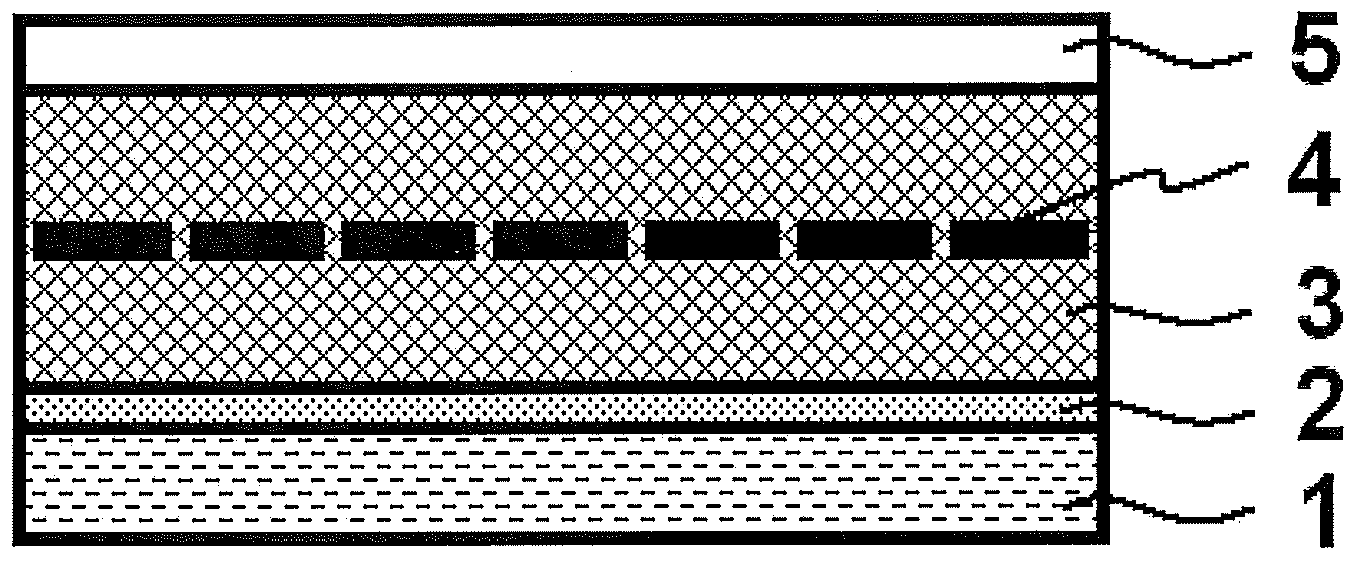

[0139] Composition (B) obtained by mixing the materials described in Table 1 at the compounding ratio described in Table 2 was melt-kneaded at 250° C. using an extruder. Then, this was extruded into a sheet form and cooled to about 60° C. with a cooling roll to obtain a thermoplastic resin sheet. This thermoplastic resin sheet was reheated to 145° C., and stretched at the ratios listed in Table 2 in the longitudinal direction by utilizing the peripheral speed difference of a plurality of roller groups.

[0140] Next, the composition (A) obtained by using the materials described in Table 1 as described in Table 2 was melt-kneaded at 250° C. using another extruder, and melt-extruded onto the thermoplastic resin sheet obtained above. A laminate with (A) / (B) structure was obtained.

[0141] Next, this laminate was reheated to 160° C., and stretched at the ratios described in Table 2 in the transverse direction by a tenter. Thereafter, after performing annealing treatment at 165°...

Embodiment 3

[0144] Composition (B) obtained by mixing the materials described in Table 1 at the compounding ratio described in Table 2 was melt-kneaded at 250° C. using an extruder. Then, this was extruded into a sheet form and cooled to about 60° C. with a cooling roll to obtain a thermoplastic resin sheet. This thermoplastic resin sheet was reheated to 145° C., and stretched at the ratios listed in Table 2 in the longitudinal direction by utilizing the peripheral speed difference of a plurality of roller groups.

[0145] Next, the composition (A) obtained by using PP1 described in Table 1 was melt-kneaded at 250° C. with another extruder, and melt-extruded on one side of the thermoplastic resin sheet obtained above to obtain a compound having ( Laminates of sequential composition of A) / (B) are passed between embossing rolls (150 lines per 1 inch, gravure (reverse cone) type) formed of rubber rolls and metal rolls, The surface on the side of the adhesive layer formed of the composition ...

Embodiment 4、5

[0149] As the material constituting the adhesive layer (A), the composition (A) described in Table 2 was used, stretched at the magnification described in Table 2, and the surface treatment by corona discharge treatment and surface treatment layer was not performed, except Other than that, the laminated body was obtained by the method similar to Example 1, and this was used as the back sheet for solar cells.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com