A kind of piezoelectric bimorph and its preparation method

A piezoelectric bimorph and bimorph technology, which is applied in piezoelectric/electrostrictive/magnetostrictive devices, circuits, electrical components, etc. device failure and other problems, to achieve the effects of stable and reliable working process, reduced diffusion depth, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

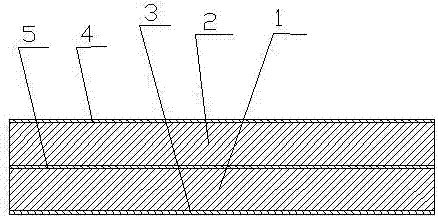

[0024] The piezoelectric bimorph of this embodiment has a wafer structure, the upper and lower piezoelectric bodies use the same soft PZT material, and the electrode layer uses silver-palladium electrodes. The schematic diagram of the structure is as follows figure 1 As shown, it includes a lower piezoelectric body 1, an upper piezoelectric body 2, a lower conductive electrode layer 3, an upper conductive electrode layer 4, and a common electrode layer 5. The lower piezoelectric body 1 and the upper piezoelectric body 2 have the same size.

[0025] The preparation method of the piezoelectric bimorph in the present embodiment comprises the following steps:

[0026] Step 1: Grind the sintered lower piezoelectric body 1 and upper piezoelectric body 2 respectively, wash them with ultrasonic water, ultrasonic alcohol and ultrasonic acetone respectively, and dry them at 120°C for use;

[0027] Step 2: Print silver-palladium paste on both sides of the lower piezoelectric body 1 and ...

Embodiment 2

[0034] The piezoelectric bimorph of this embodiment has a rectangular structure, the upper and lower piezoelectric bodies are all made of the same hard PZT material, and the electrode layer is made of silver electrodes; the structure includes a lower piezoelectric body 1, an upper piezoelectric body 2, a lower conductive electrode layer 3, The upper conductive electrode layer 4, the common electrode layer 5, and the lower piezoelectric body have the same size as the upper piezoelectric body.

[0035] The preparation method of the piezoelectric bimorph in the present embodiment comprises the following steps:

[0036] Step 1: Grind the sintered lower piezoelectric body 1 and upper piezoelectric body 2 respectively, wash them with ultrasonic water, ultrasonic alcohol and ultrasonic acetone respectively, and dry them at 120°C for use;

[0037] Step 2: Print silver paste on the two sides of the lower piezoelectric body 1 and the upper piezoelectric body 2 respectively by printing p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com