Buoyancy-type liquid level meter

A liquid level gauge and buoyancy type technology, applied in the field of buoyancy type liquid level gauges, can solve problems such as inability to meet requirements, and achieve the effects of low manufacturing cost, low temperature, and improved accuracy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

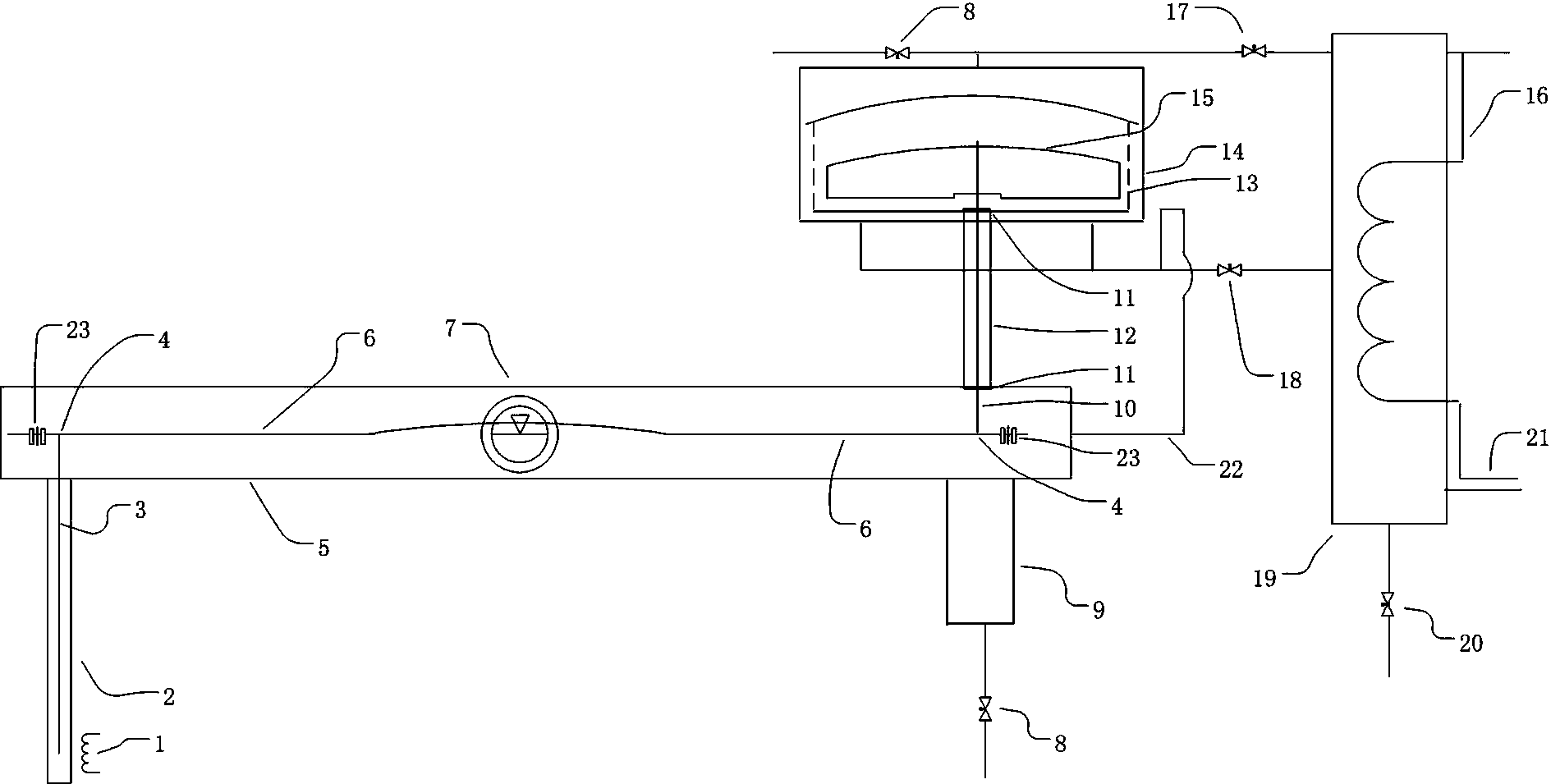

[0044] (1), open the upper and lower two holes from the steam drum wall, and connect the upper and lower connecting pipes of the mother water level measuring cylinder 19. Multiple sub buoys with different heights can be connected to the mother cylinder. The height of these two pipes will meet the height requirements of all sub-tubes drawn from the mother tube.

[0045] Master cylinders are not required. When there are multiple water level measuring switches with different heights, the mother barrel can reduce the openings on the wall of the steam drum, and the temperature in the mother buoy can be made closer to the temperature in the measured container, and can be installed close to the measured container, which can Reduce measurement errors.

[0046] (2), lead the heat tracing pipe from the steam side of the mother cylinder to trace the heat around the mother cylinder. It is also possible to install the mother barrel close to the wall of the steam drum, and do a good job ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com