Temperature-adjustable and resistance-adjustable fluidized wind system of circulating fluidized bed boiler

A technology of circulating fluidized bed and wind system, which is applied in the direction of fluidized bed combustion equipment, burning fuel in molten state, lighting and heating equipment, etc. Great impact and other problems, to achieve the effect of shortening the start-up time, saving fuel, and ensuring stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

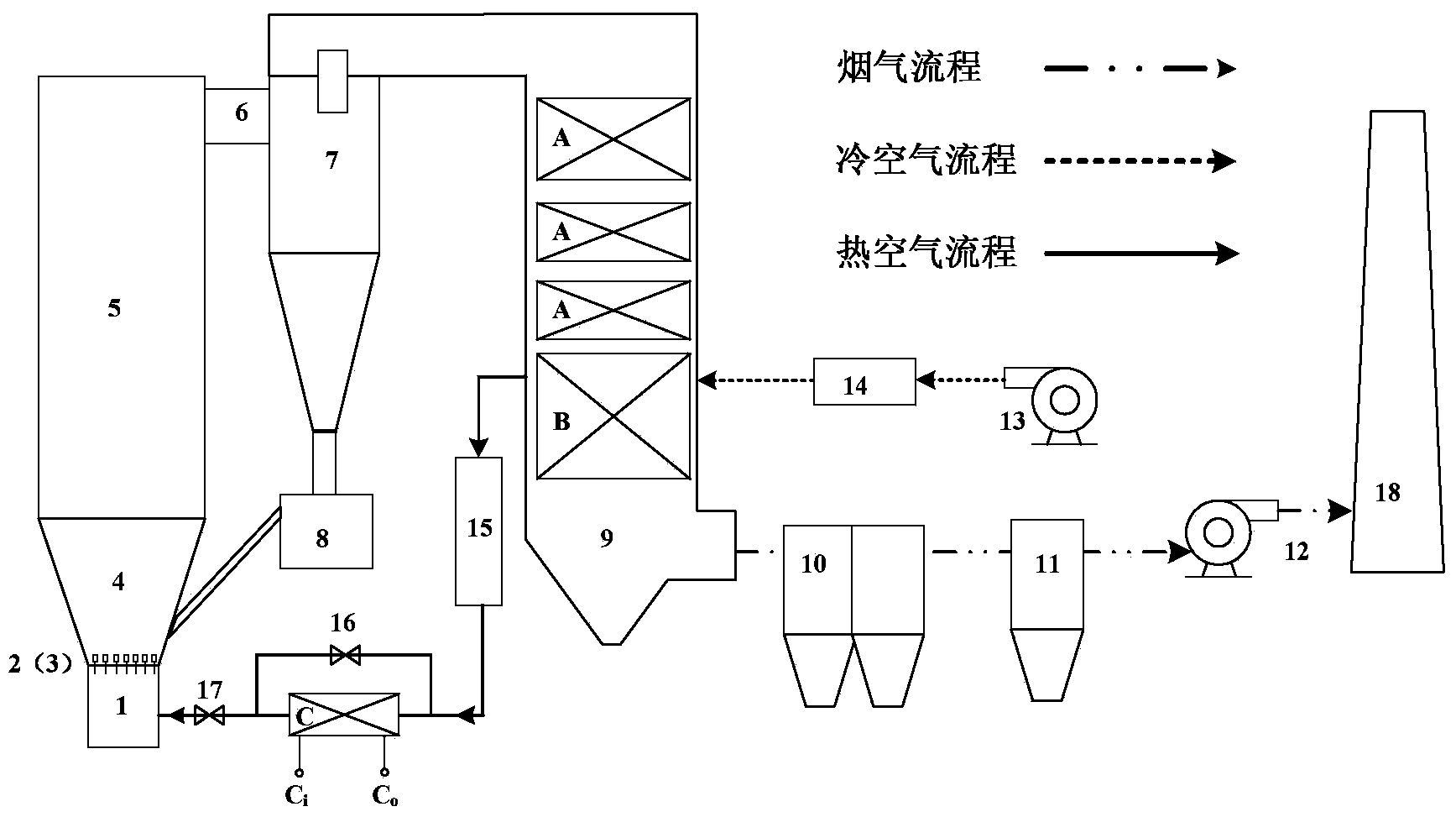

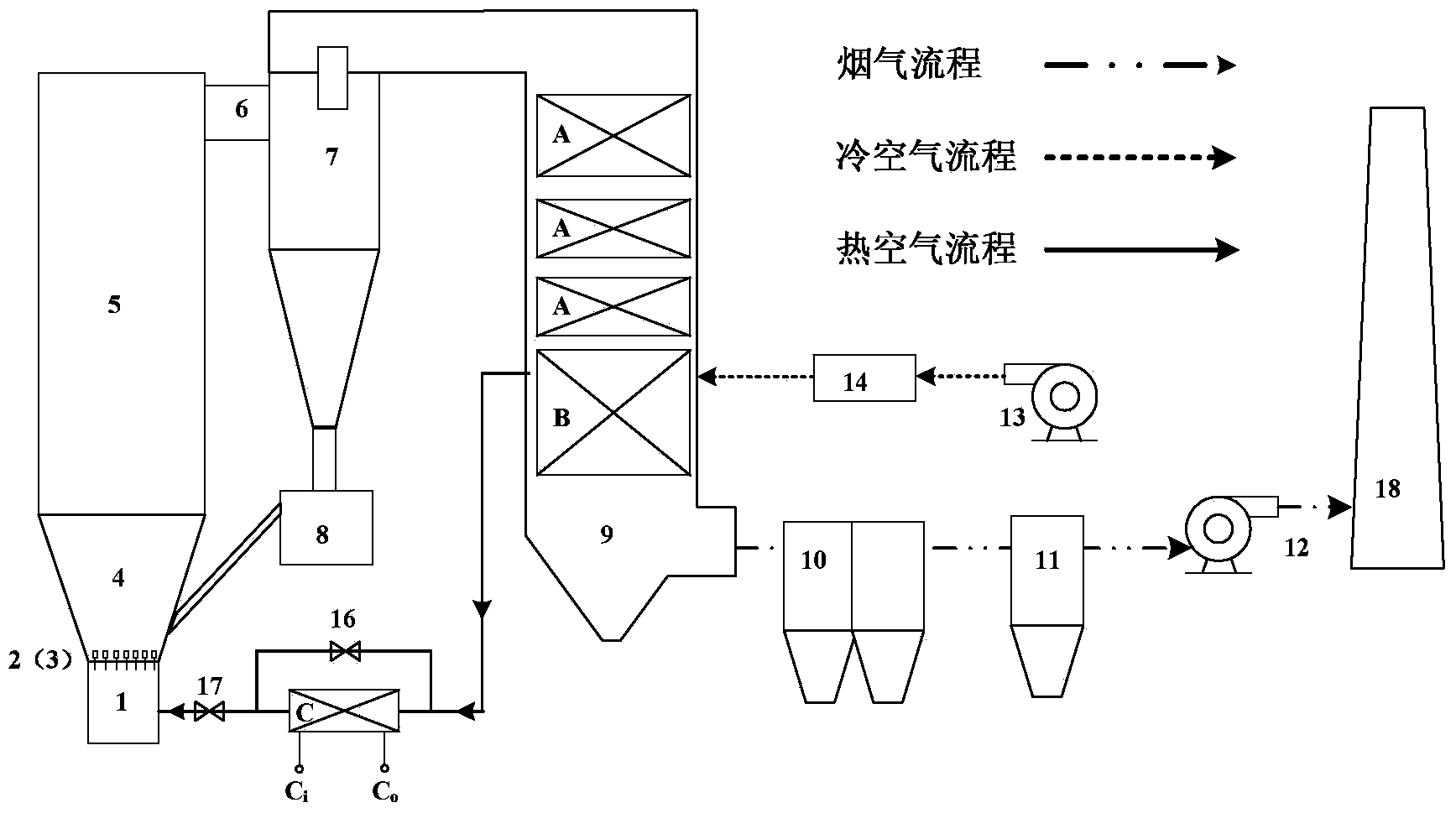

[0047] figure 1 Shown is a 300MW circulating fluidized bed boiler. When the load is above 75%, the primary air rate is 60%, the corresponding bed temperature is 960°C, the primary hot air temperature is 230°C, and the resistance of the air distribution plate is 6.8kPa. To implement SO 2 The emission concentration is lower than 200mg / m 3 , the calcium-sulfur molar ratio was as high as 4.5 during operation. The temperature of the primary hot air is reduced to 170°C through the primary hot air heat exchanger C, the resistance of the corresponding air distribution plate is reduced to 5.2kPa, the temperature of the dense phase area is reduced to 920°C, and the current of the primary fan is reduced to 45A. Under the same operating conditions, calcium sulfur SO can be realized under the condition of molar ratio as high as 2.8 2 The emission concentration is lower than 200mg / m 3 , the effect of energy saving and emission reduction is remarkable.

[0048] In this application exam...

Embodiment 2

[0052] figure 1 Shown is a 200MW circulating fluidized bed boiler. The boiler is equipped with a start-up burner. When operating at 50% load in winter, the primary hot air temperature is 150°C, the resistance of the air distribution plate is only 1.6kPa, and the slag leakage of the air cap is serious. coking. The temperature of the primary hot air is raised to 200°C through the primary hot air heat exchanger C, and the heat exchange medium in the primary hot air heat exchanger C is steam from the auxiliary steam header. After the primary hot air temperature increases, the resistance of the corresponding air distribution plate rises to 2kPa, the phenomenon of poor fluidization and slag leakage from the air cap disappears, and the operating safety of the unit is improved.

Embodiment 3

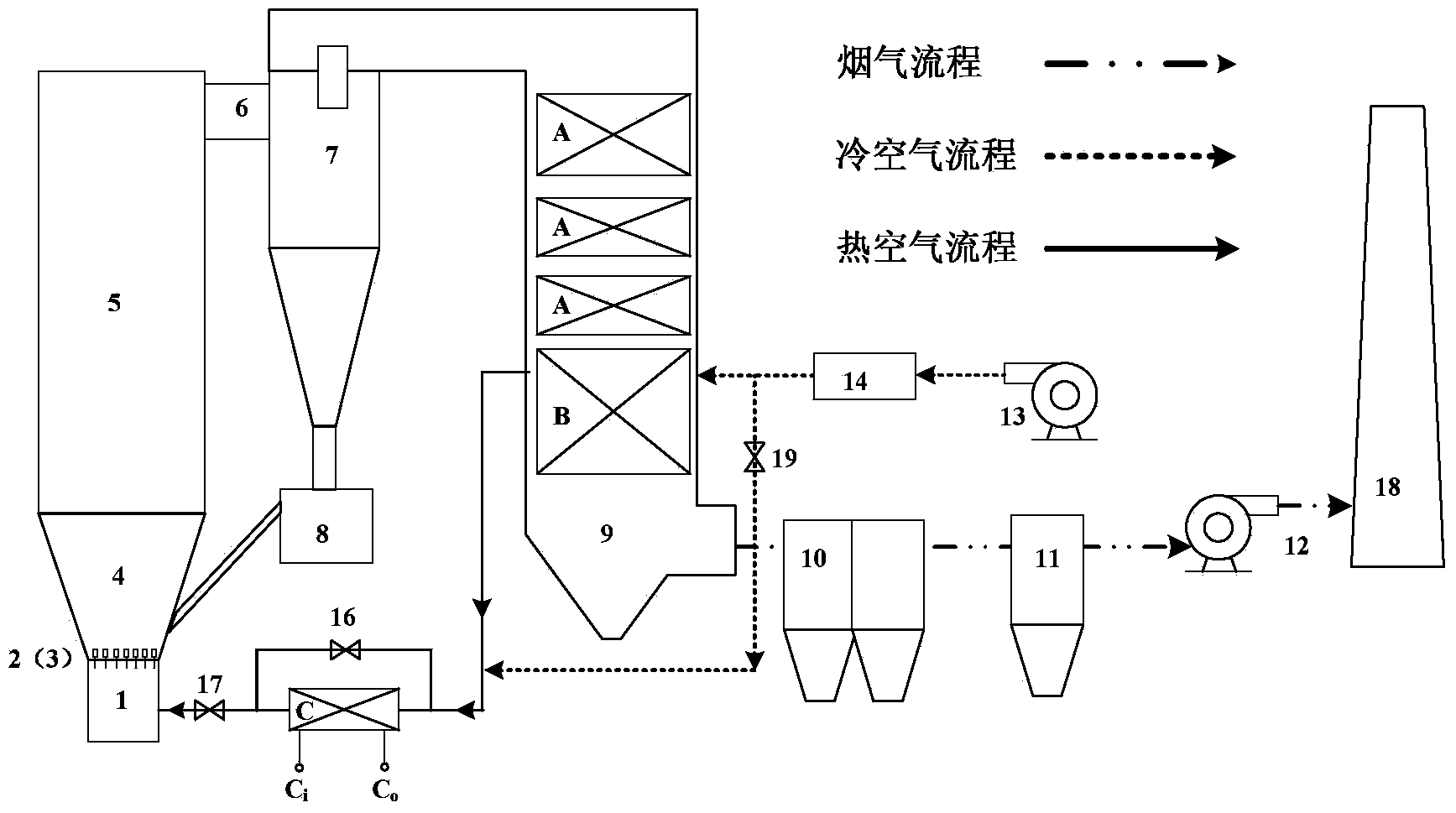

[0054] figure 2 Shown is a 150MW circulating fluidized bed boiler. The boiler does not have a start-up burner, and can only be started by the oil gun on the bed, and the fuel consumption is high during the start-up process. During start-up, the temperature of the fluidizing air is increased from 50°C to 150°C by starting the primary hot-air heat exchanger C. The heat exchange medium in the primary hot-air heat exchanger C is steam from the auxiliary steam header, and the start-up time is shortened by about 2 hours. Significant savings in starting oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com