Self-relieving non-return-oil oil atomizer and refitting method of same

A technology of self-relieving pressure and fuel injectors, which is applied to fuel injection devices, charging systems, machines/engines, etc. It can solve problems such as fuel leakage, reliability problems of drainage pipeline devices, etc., to reduce energy loss and simplify modification methods , Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

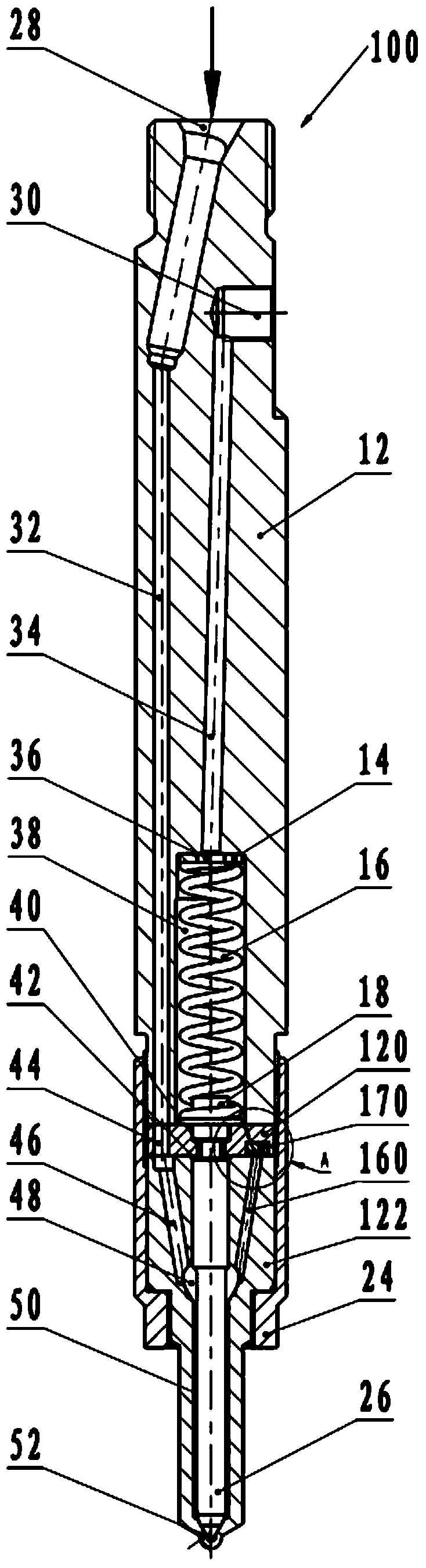

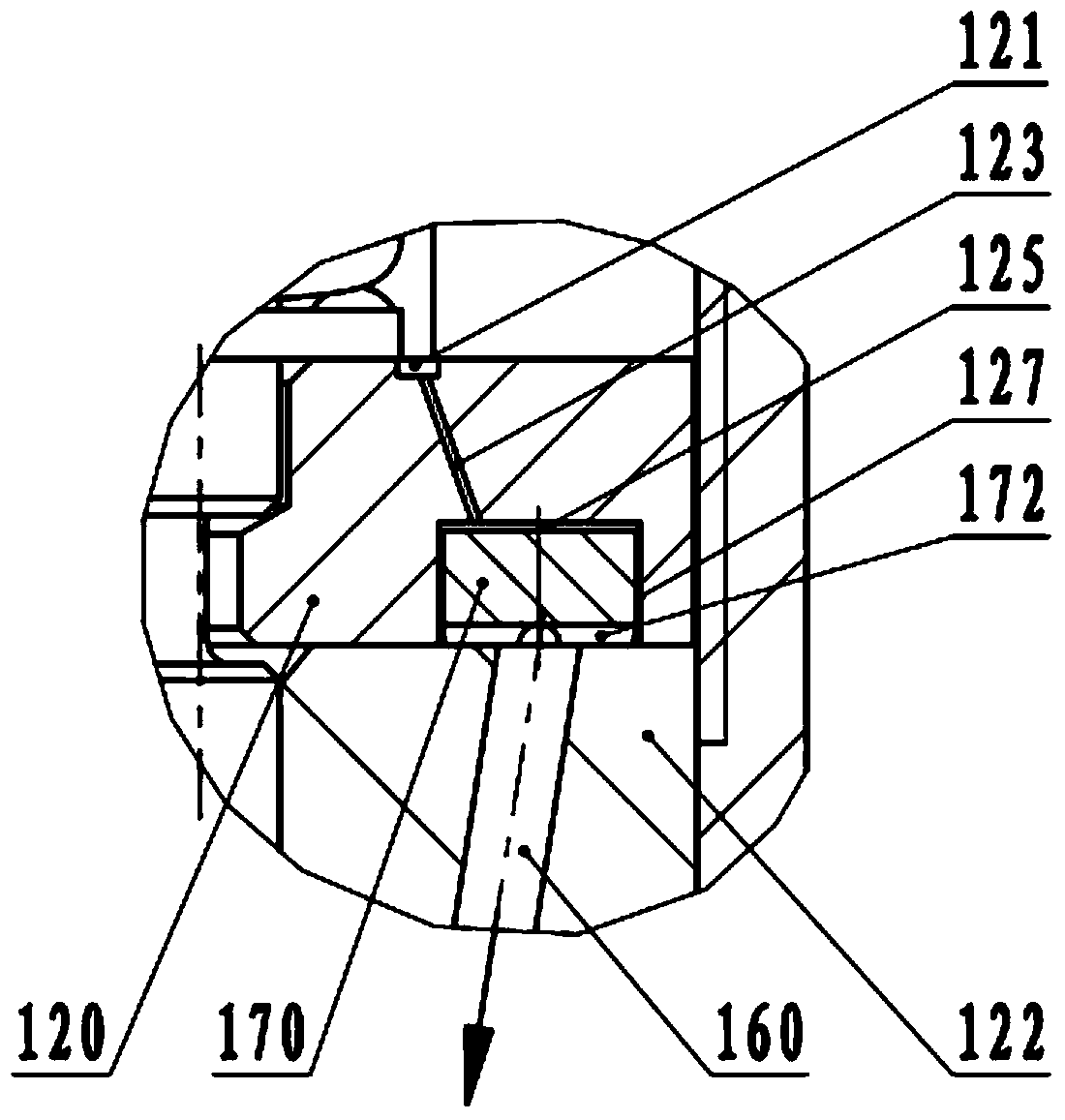

[0039] The present invention includes a self-relieving pressure-free oil-return fuel injector and its refitting method. In order to better introduce the technical solution adopted in the present invention, firstly, a known traditional mechanical fuel injector is converted into a self-releasing pressure-free oil-return fuel injector. method, and then introduce a self-relieving pressure-free oil-return injector with a new structure directly formed by this technology in order to better understand the technical solution of the present invention.

[0040] A method for refitting a traditional mechanical fuel injector into a self-relieving pressure-free fuel injector.

[0041] supply:

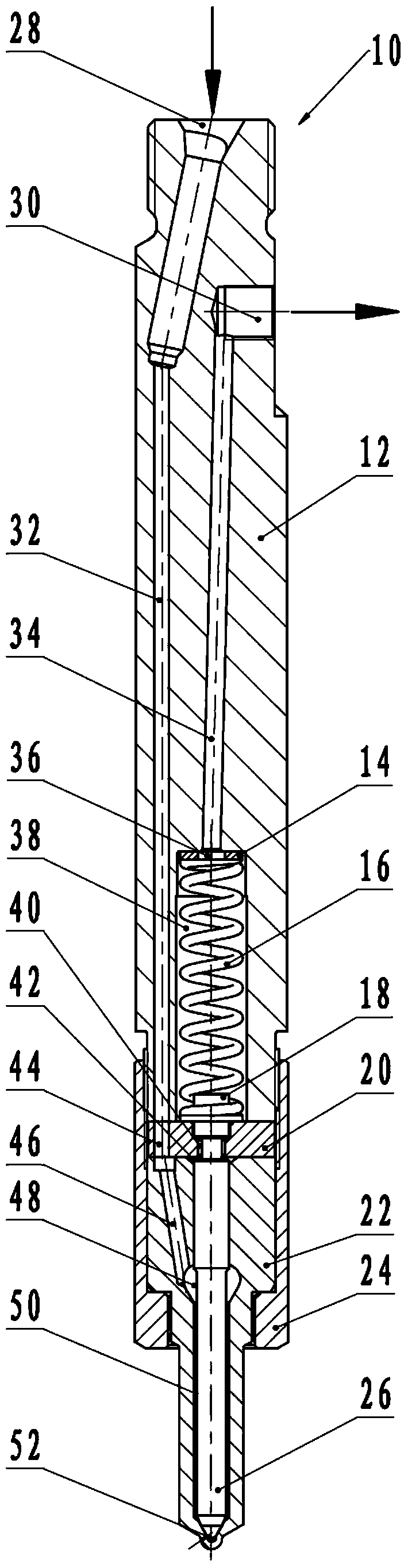

[0042] like figure 1 The traditional mechanical injector 10 shown is one, including: injector body 12, spring washer 14, spring 16, spring seat 18, pressure plate 20, positioning pin (not shown), nozzle body 22, tight cap 24, needle valve 26; also provide figure 2 One each of a check valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com