Coal slurry and preparation method thereof

A technology of coal slurry and nano slurry, which is applied in the petroleum industry, liquid carbon-containing fuel, fuel, etc., can solve the problem of low concentration of coal slurry, achieve the prospect of large-scale industrial application, high concentration of slurry, and high solid content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1. Raw materials

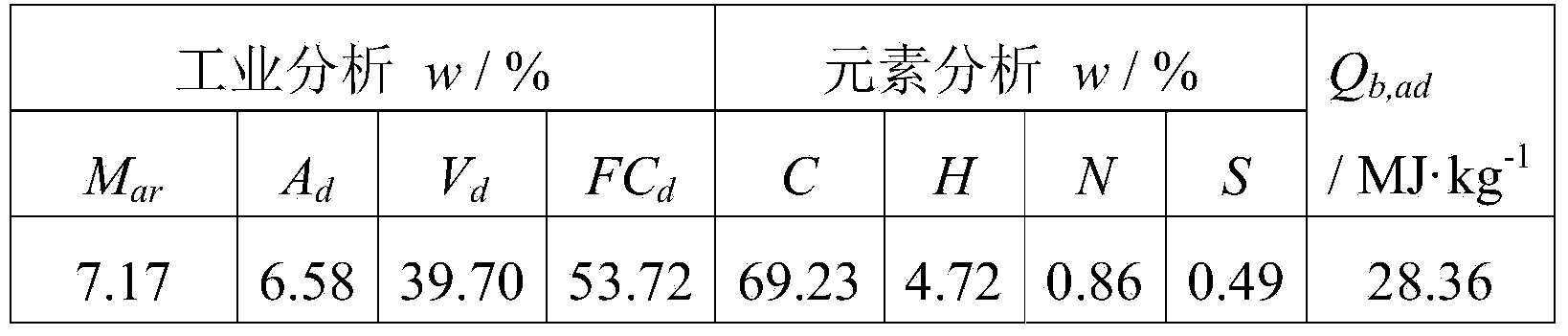

[0031] (1) Lignite, the specific composition is shown in the table below.

[0032]

[0033] (2) Dispersant: sodium naphthalenesulfonate

[0034] (3) Non-polar solvent: kerosene

[0035] (4) Nano powder: nano calcium carbonate, diameter 50nm

[0036] (5) water

[0037] 2. Preparation conditions

[0038] (1) Raw material ratio, weight fraction. 153 parts by weight of lignite (after drying, remove free water in coal), 118 parts by weight of water, 1.5 parts by weight of dispersant, 0.75 parts by weight of non-polar solvent, 0.15 parts by weight of nano Powder.

[0039] (2) Preparation method. First, the non-polar solvent is divided into B solvent and C solvent in two parts (the mass ratio of B solvent and C solvent is 1:1), B solvent is added to the pulverized lignite, and stirred for 30 minutes to make the surface of lignite particles become It is hydrophobic; C solvent is added to nano-powder, and stirred for 30 minutes to form a nano-slurry...

Embodiment 2

[0048] 1. Raw materials

[0049] (1) Lignite, the specific composition is shown in the table below.

[0050]

[0051] (2) Dispersant: sodium naphthalenesulfonate

[0052] (3) Non-polar solvent: kerosene

[0053] (4) water

[0054] 2. Preparation conditions

[0055] (1) Raw material ratio, weight fraction. 147 parts by weight of lignite (after drying), 118 parts by weight of water, 1.5 parts by weight of dispersant, and 0.75 parts by weight of non-polar solvent.

[0056] (2) Preparation method. First, the non-polar solvent is added to the pulverized lignite and stirred for 30 minutes to make the surface of the lignite particles hydrophobic to form a modified oil-coal slurry; the modified oil-coal slurry, water and dispersant mixing to form a raw material mixture; finally, the raw material mixture was stirred for 60 minutes to obtain the slurry.

[0057]3. Product performance indicators

[0058] (1) Appearance shape: gray-black paste. At 25 degrees Celsius, the appar...

Embodiment 3

[0065] 1. Raw materials

[0066] (1) Bituminous coal, the specific composition is shown in the table below.

[0067]

[0068] (2) Dispersant: sodium naphthalenesulfonate

[0069] (3) Non-polar solvent: kerosene

[0070] (4) Nano powder: nano calcium carbonate, diameter 50nm

[0071] (5) water

[0072] 2. Preparation conditions

[0073] (1) Raw material ratio, weight fraction. 213 parts by weight of bituminous coal (after drying), 118 parts by weight of water, 1.5 parts by weight of dispersant, 0.75 parts by weight of non-polar solvent, and 0.15 parts by weight of nanometer powder.

[0074] (2) Preparation method. First, divide the non-polar solvent into B solvent and C solvent (the mass ratio of B solvent and C solvent is 1:1), B solvent is added to the pulverized bituminous coal, and stirred for 20 minutes to make the surface of the bituminous coal particles change. It is hydrophobic; C solvent is added to nanopowder, and stirred for 20 minutes to form a nanoslurry;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com