Method for preparing high-alkali coal water slurry from coking wastewater

A technology for coking wastewater and coal-water slurry, which is applied in the petroleum industry, liquid carbon-containing fuels, fuel additives, etc., can solve the problems of low concentration of coal-water slurry, unsatisfactory gasification efficiency, and easy sedimentation of pulverized coal. Meet process requirements, achieve low-cost treatment, and improve gasification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

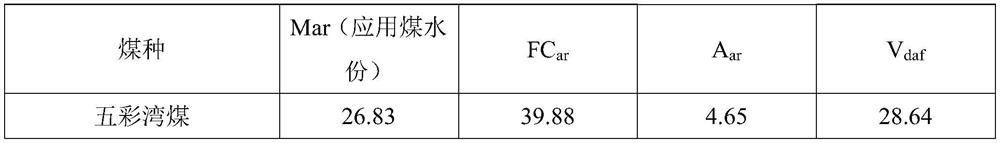

[0034] When preparing coal-water slurry, the high-alkali coal is used as Wucaiwan coal in Zhundong, Xinjiang, which is ground and sieved to a particle size below 200 μm. The industrial analysis and ash composition of the Wucaiwan coal are shown in Table 1 and Table 2 below, respectively.

[0035]

[0036] Table 1 Wucaiwan Coal Industry Analysis / %

[0037] Table 1, M ar Indicates coal moisture, FC ar Indicates that coal fixes carbon, A ar Indicates coal ash content, V daf Indicates coal volatiles.

[0038]

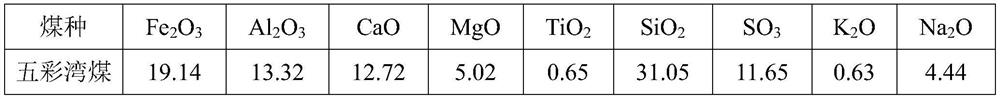

[0039] Table 2 Ash composition analysis / %

[0040] From the ash composition in Table 2, the content of alkali metal Na in Wucaiwan coal is much higher than that of ordinary coal.

[0041] The coking waste water that adopts, through testing, the content of ammonia nitrogen in it is 2684mg / L, the content of phenols is 3105mg / L, COD (chemical oxygen demand) is 21000mg / L.

[0042] The additives that adopt include 2 parts of stabilizing agent (below unless otherwise ...

Embodiment 2

[0045] When preparing coal-water slurry, the high-alkaline coal is made of Xinjiang Zhundong Wucaiwan coal, which is ground and sieved to a particle size below 200 μm.

[0046] The coking waste water that adopts, through testing, the content of ammonia nitrogen in it is 2684mg / L, the content of phenols is 3105mg / L, COD (chemical oxygen demand) is 21000mg / L.

[0047] The additives that adopt include 1 part of stabilizer, 0.05 part of dispersant, 0.07 part of emulsifier and 3 parts of concentration of formaldehyde solution, wherein the stabilizer adopts polyacrylamide, and the dispersant includes 6 parts of sodium lignosulfonate and 4 parts sodium naphthalenesulfonate, emulsifiers include 8 parts acetic acid and 2 parts sulfuric acid.

[0048] During preparation, the above 60 parts of Wucaiwan coal powder smaller than 200 μm, 30 parts of coking wastewater and 4 parts of additives were stirred at 80° C. to make coal water slurry.

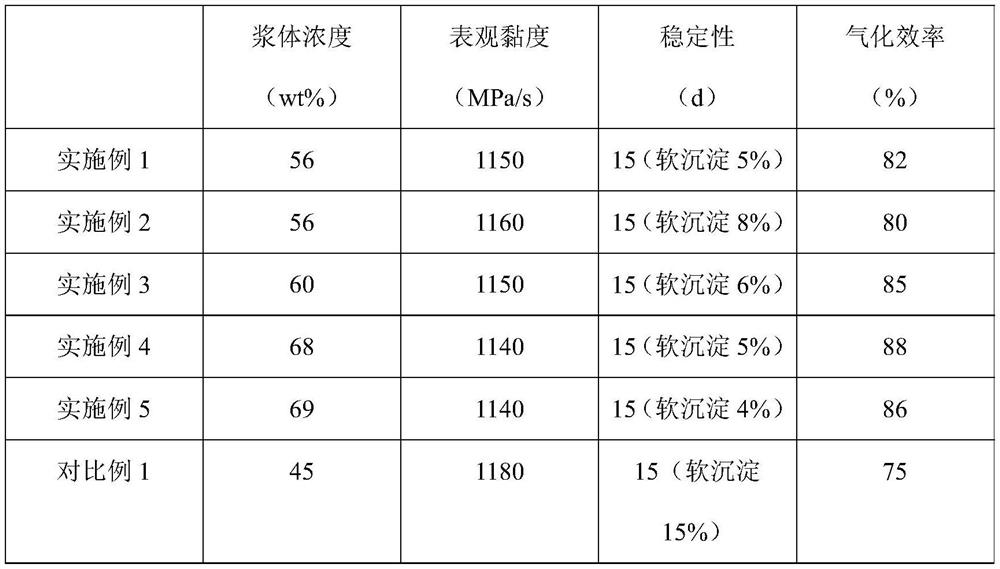

[0049] In Example 2, the prepared coal-water sl...

Embodiment 3

[0051] When preparing coal-water slurry, the high-alkaline coal is made of Xinjiang Zhundong Wucaiwan coal, which is ground and sieved to a particle size below 200 μm.

[0052] The coking waste water that adopts, through testing, the content of ammonia nitrogen in it is 2684mg / L, the content of phenols is 3105mg / L, COD (chemical oxygen demand) is 21000mg / L.

[0053] The additives that adopt include 3 parts of stabilizer, 0.2 part of dispersant, 0.08 part of emulsifier and 5 parts of concentration of formaldehyde solution, wherein the stabilizer adopts polyacrylamide, and the dispersant includes 5.5 parts of sodium lignosulfonate and 3.5 parts sodium naphthalene sulfonate, emulsifier consisting of 7 parts acetic acid and 1.5 parts sulfuric acid.

[0054]During preparation, the above 63 parts of Wucaiwan coal powder smaller than 200 μm, 37 parts of coking wastewater and 5 parts of additives were stirred at 85° C. to make coal water slurry.

[0055] In Example 3, the prepared co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com