Method for assembling cloth rolling machine advancing strips

An assembly method and a technology for advancing strips, which are applied in the directions of winding strips, transportation and packaging, thin material processing, etc., can solve the problems of difficult removal of residues on the surface of the reel, reducing the working efficiency of the cloth rolling machine, and difficult advancing effects. , to achieve the effect of novel design ideas, good promotion effect, economical and practical effect

Inactive Publication Date: 2014-03-19

孙光恩

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Due to the different materials of the cloth, it is difficult for the propulsion strips with the same friction force to have a good propulsion effect on the cloth of different materials; The time is long, it is not easy to replace, and the residue on the surface of the roller is not easy to remove, which reduces the working efficiency of the cloth winding machine

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

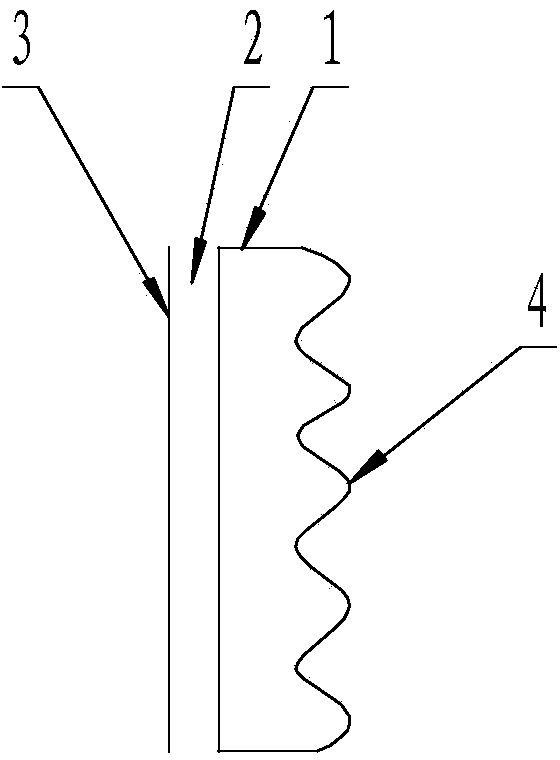

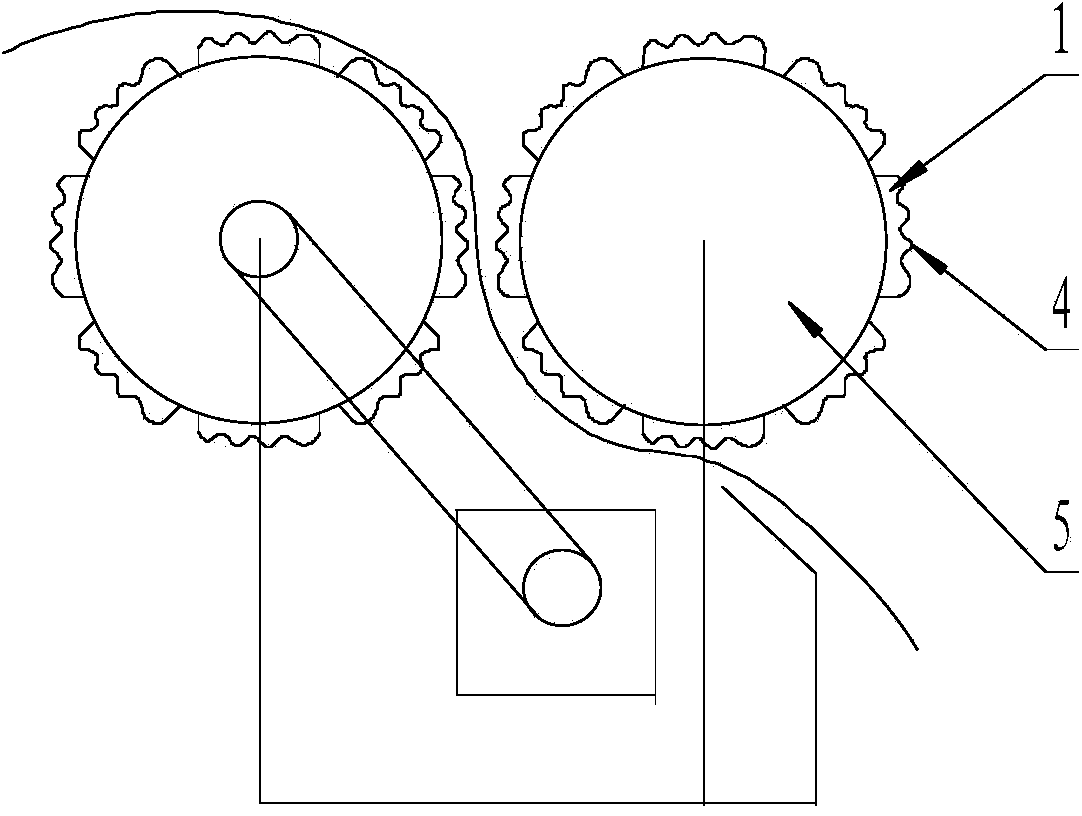

[0021] Remove the sticker 3 on the back of the propelling bar, and glue the adhesive layer 2 corresponding to the reel 5, and each reel 5 has at least 4 propelling bars.

Embodiment 2

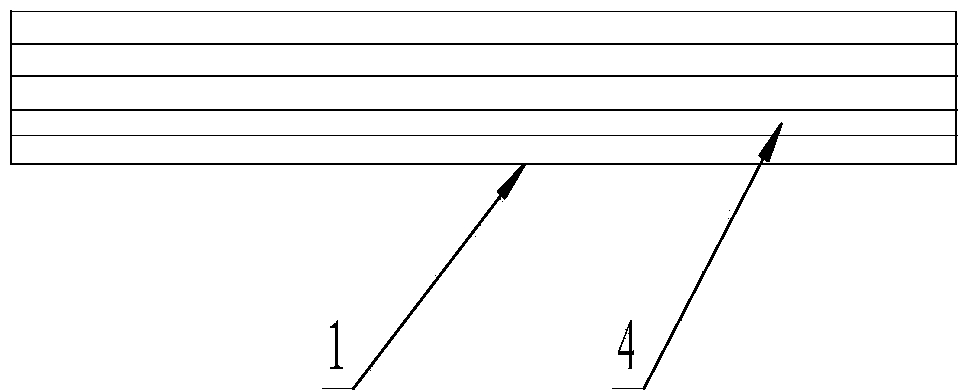

[0023] The propelling bar is made of rubber material, and the surface of the propelling bar is processed with wave patterns 4.

Embodiment 3

[0025] The length of the push bar is equal to the length of the reel 5.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a method for assembling cloth rolling machine advancing strips. The method relates to base plates, glue layers, pasters, wavy grains and rolling wheels. The pasters on the back faces of the advancing strips are torn down, the glue layers are bonded to the corresponding rolling wheels, and the number of the advancing strips on each rolling wheel is at least four. The friction force of the surfaces of the rolling wheels is effectively guaranteed, the advancing strips with different sizes of friction force can be adopted according to different cloths, and it is guaranteed that the advancing strips have the good advancing effect on the cloths.

Description

[0001] Technical field [0002] The invention relates to the field of cloth production and processing, in particular to a method for assembling a cloth rolling machine propelling strip. [0003] Background technique [0004] In the process of advancing the cloth, the cloth winder relies on the push bar on the surface of the cloth winder to generate friction on the cloth, and the cloth pushes forward under the action of the friction force of the push bar on the two reels. Due to the different materials of the fabrics, it is difficult for the propelling strips that produce the same friction to have a better propelling effect on the fabrics of different materials; the existing propelling strips of the cloth winding machine are long strips wound and fixed on the circumferential surface of the reel, and the replacement process is costly. Time is long, not easy to replace, and the residue on the surface of the reel is not easy to remove, which reduces the working efficiency of the cloth ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B65H27/00B65H20/02

Inventor 孙光恩

Owner 孙光恩

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com