Insulator detecting robot

An insulator detection and robot technology, applied in manipulators, manufacturing tools, etc., can solve the problems of inability to obtain insulator status information in real time, high labor intensity, low detection efficiency, etc., and achieve the effect of simple structure, avoiding potential safety hazards and improving detection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

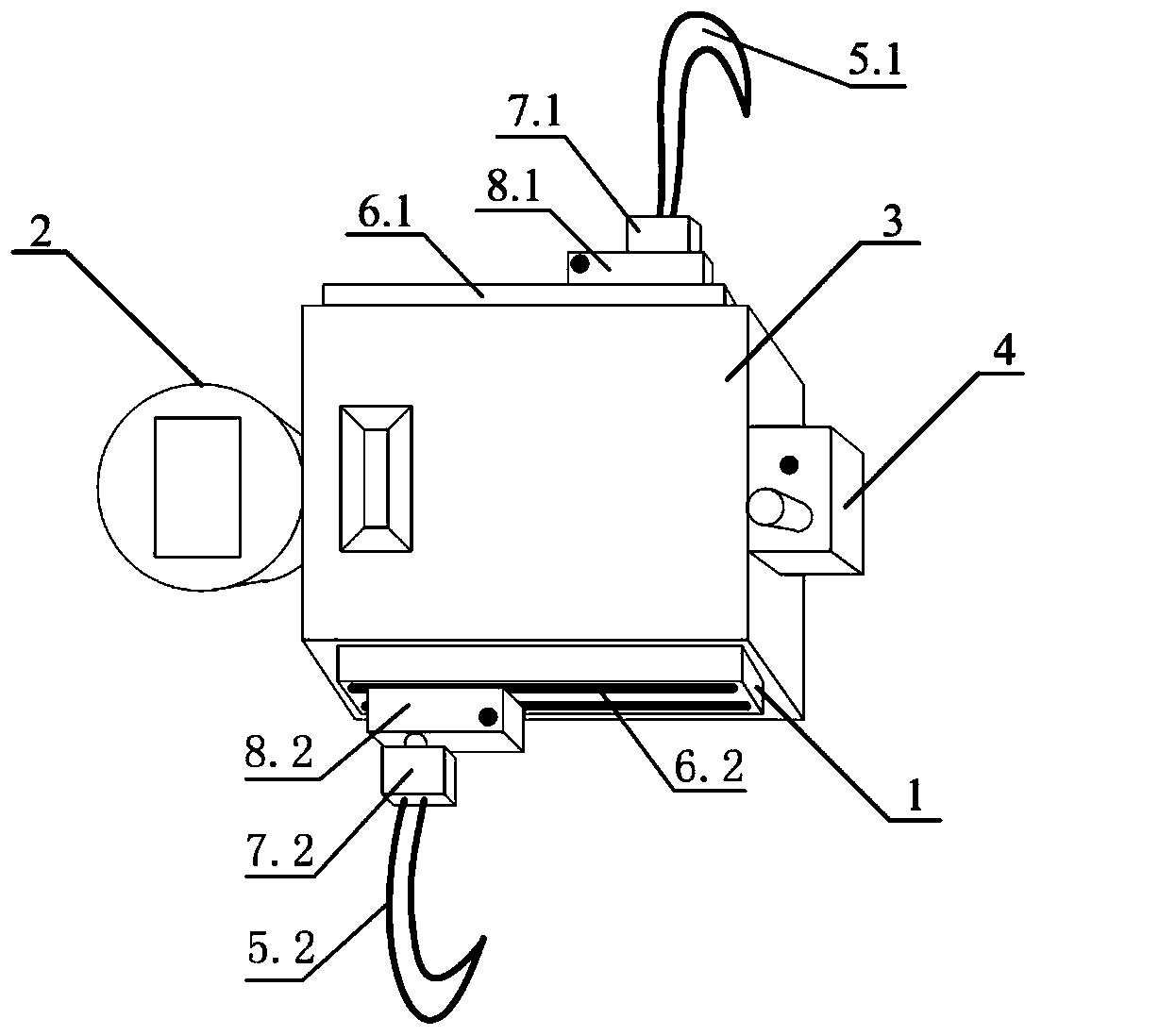

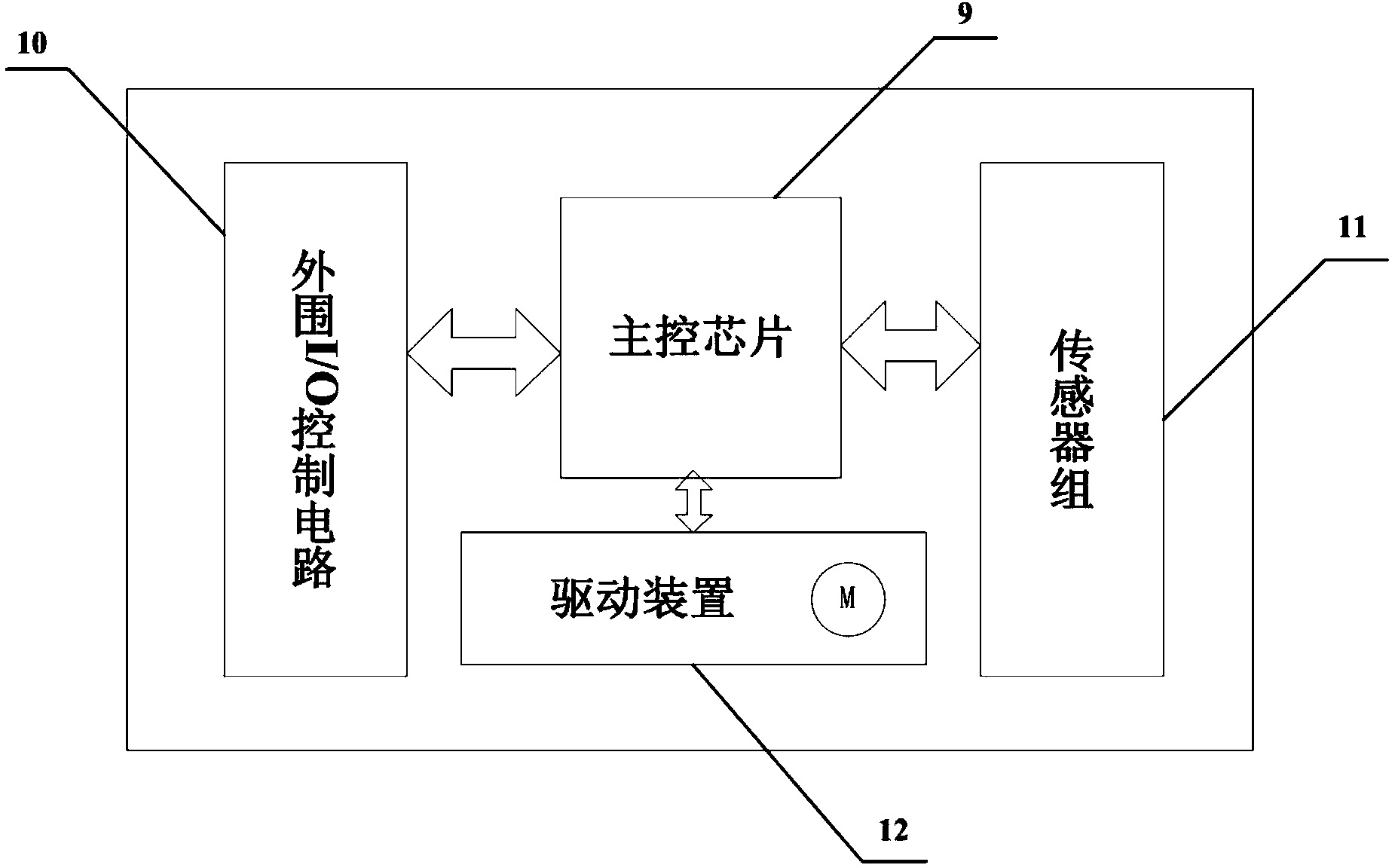

[0017] Such as figure 1 and figure 2 As shown, the insulator detection robot of the present invention includes: a connecting rod transmission device 1, a control device 3, a wireless communication device 4 and an insulator detection device 2, and the wireless communication device 4 and the insulator detection device 2 are respectively connected to the control device 3.

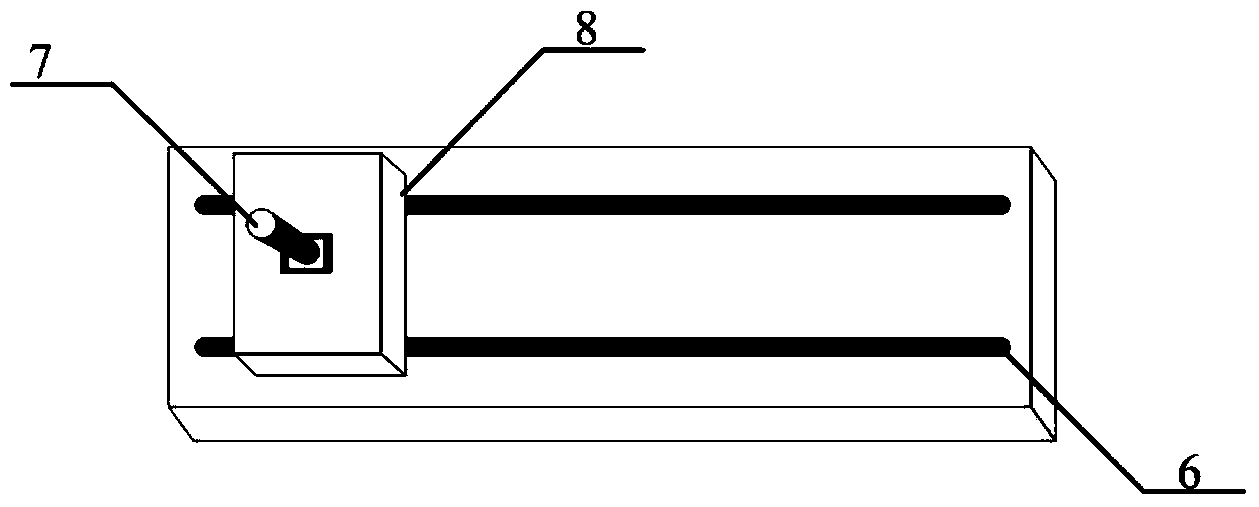

[0018] The connecting rod transmission device 1 includes sliding guide rails 6 respectively arranged on the top and bottom ends of the control device 3, the sliding guide rail 6 is provided with a sliding block 8, the sliding block 8 is provided with a steering bearing 7, and the steering bearing 7 is connected with a hook-shaped motion measuring arm 5 . In this embodiment, the top of the control device 3 is provided with an upper sliding guide rail 6.1, the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com