A cast iron anode mold for increasing the amount of copper poured and its production method

A production method and anode technology, applied in casting molds, casting mold components, casting molding equipment, etc., can solve problems such as improper material selection, unreasonable structural design, and short service life of cast iron anode molds, and achieve significant economic and social benefits , reduce the labor load and reduce the effect of internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

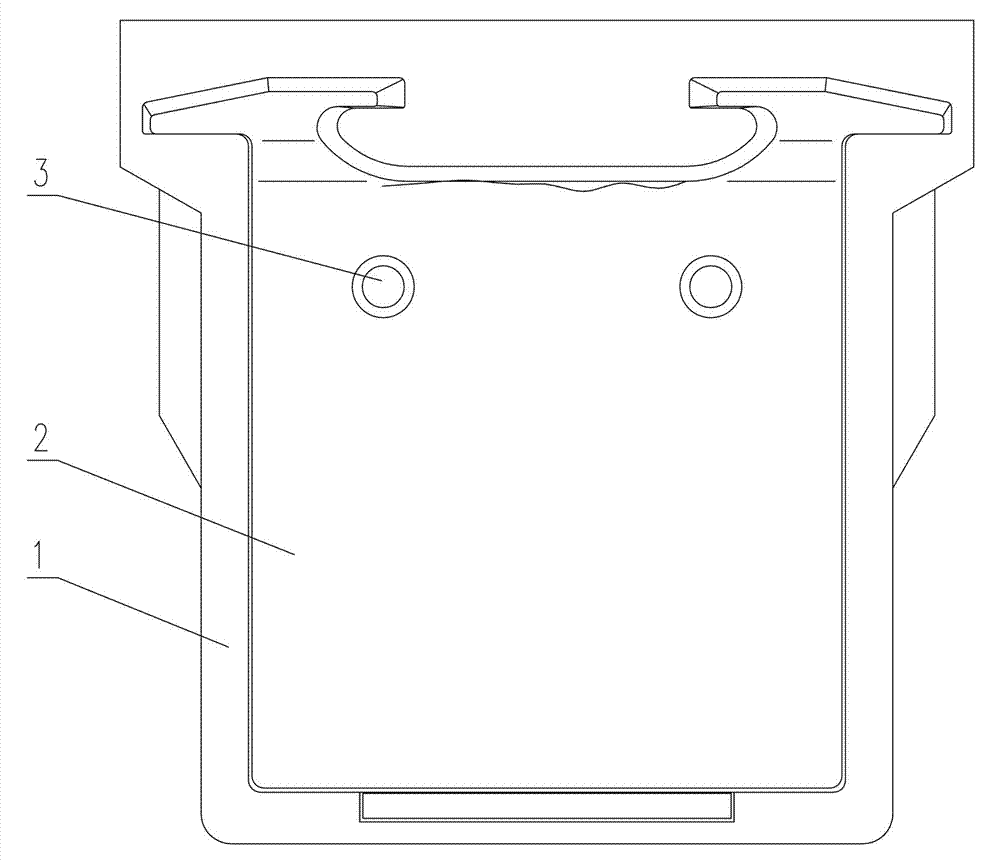

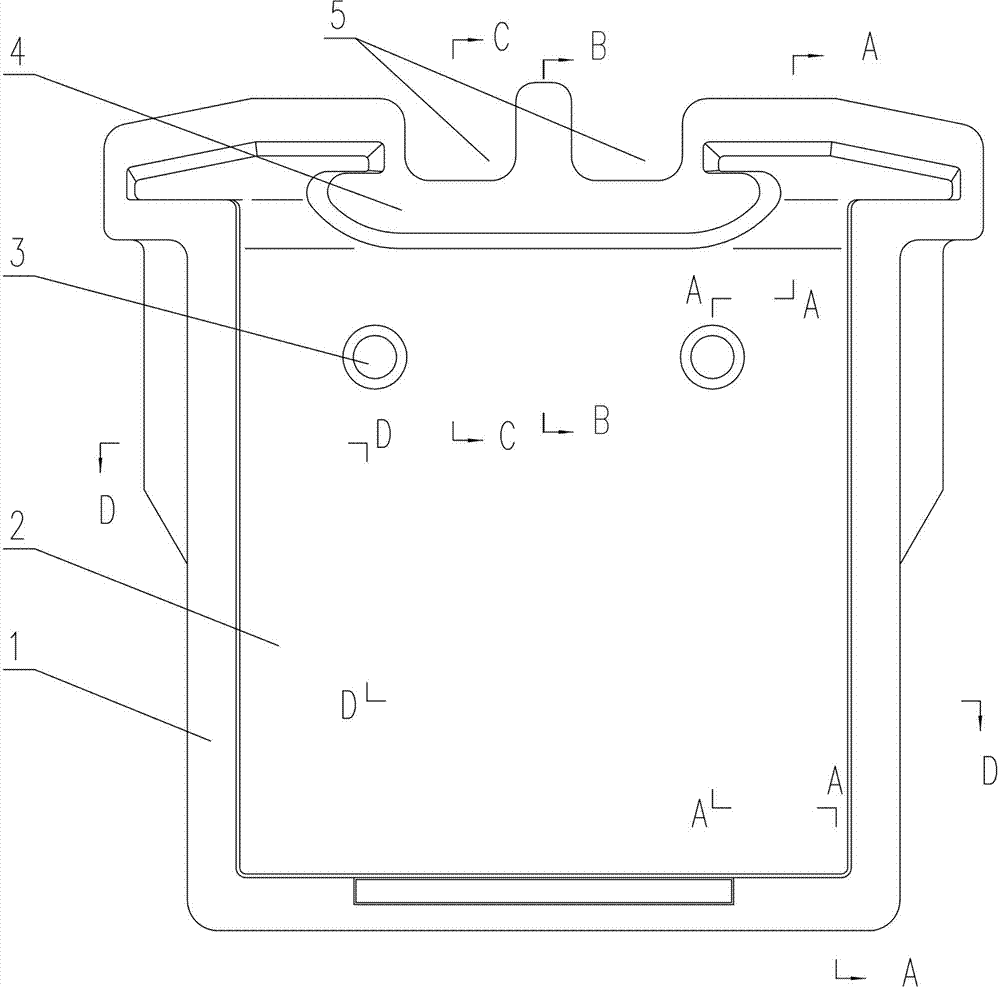

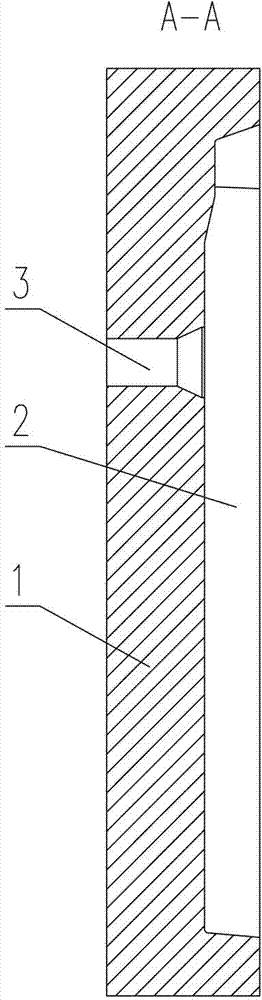

[0016] Example 1: see Figure 2-5 , a cast iron anode mold that increases the amount of copper pouring, it has a mold body 1, a copper pouring cavity 2 is opened on the mold body 1, and two release films are arranged on the mold body 1 and located on the upper part of the copper pouring cavity 2 The thimble hole 3 is characterized in that: the chemical composition weight percentage of the mold body 1 is: C: 3.6, Si: 1.6, Mn: 0.4, P<0.1, S<0.1, and the balance is Fe; the mold body There are two symmetrically arranged grooves 5 arranged in the middle section of the top of 1, forming a mountain-shaped surrounding structure 4.

[0017] Production Example 1 The production method of the cast iron anode mold with increased copper pouring amount is as follows: use 90% of the anode mold return material + 10% newborn iron, put it into the cupola for smelting, use dry mold clay sand molding, and pour the molten iron at a temperature of 1340°C , Insulated in the sand mold for 36 hours to...

example 2

[0018] Example 2: The physical structure of the cast iron anode mold of this embodiment is the same as Example 1, and its chemical composition weight percentage is: C: 3.7, Si: 1.5, Mn: 0.5, P<0.1, S<0.1, and the balance is Fe; this implementation The production method of example cast iron anode mold is basically the same as example 1, but the molten iron temperature is 1360 ℃, and the holding time in the sand mold is 38 hours.

example 3

[0019] Example 3: The physical structure of the cast iron anode mold of this embodiment is the same as Example 1, and its chemical composition weight percent is: C: 3.8, Si: 1.8, Mn: 0.6, P<0.1, S<0.1, and the balance is Fe; this implementation The production method of example cast iron anode mold is basically the same as example 1, but the molten iron temperature is 1380 ℃, and the holding time in the sand mold is 40 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com