Device for testing supercritical water fluidized bed two-phase flow and heat-transfer characteristic

A heat transfer characteristic and supercritical technology, applied in the field of multiphase flow, can solve problems such as heat imbalance, temperature fluctuation, and flow linear increase, so as to reduce heating area and power, ensure stability, and effectively control the total flow range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

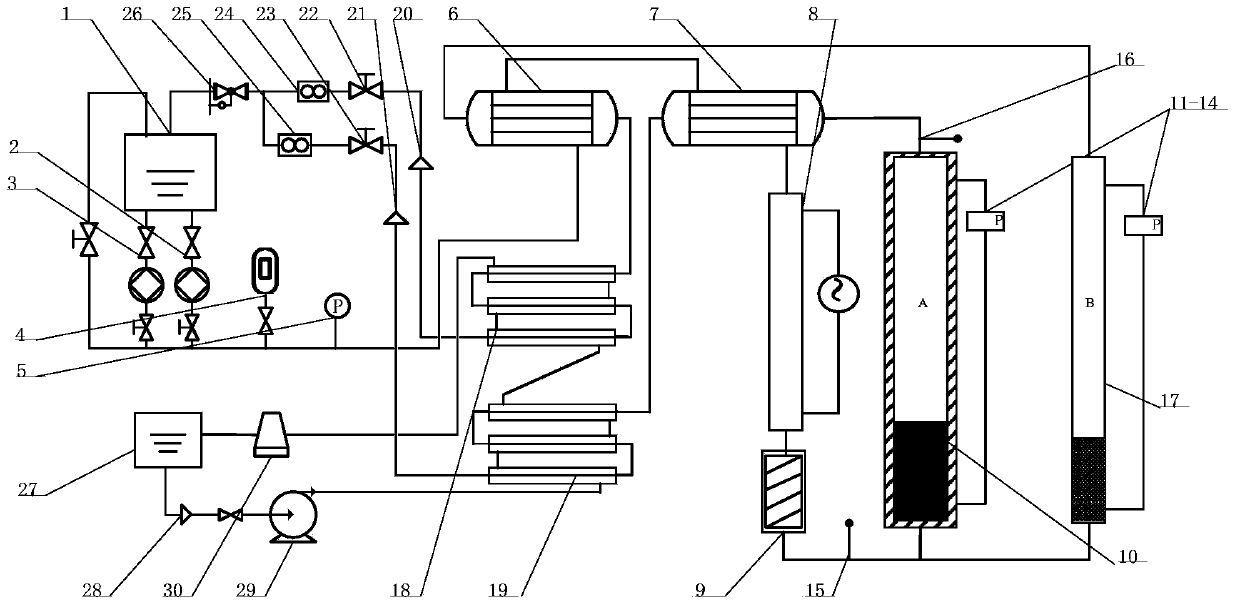

[0021] As shown in Figure 1, the supercritical water fluidized bed two-phase flow and heat transfer characteristic testing device of the present invention is composed of a main circulation system and an auxiliary circulation system, and the main circulation system includes No. I water tank 1, the first plunger pump 2 (high pressure ) and the second plunger pump 3 (high pressure), pulse damper 4, pressure sensor 5, No. Ⅰ counterflow regenerator 6, No. Ⅱ counterflow regenerator 7, preheater 8, coil heater 9, Fluidized bed A test section 10, differential pressure sensor 11-14, armored thermocouple 15-16, fluidized bed B test section 17, No. 1 counterflow cooler 18 (casing type), No. 2 counterflow cooler 19 ( Casing type), No. I filter 20, No. II filter 21, No. I flow regulating valve 22, No. II flow regulating valve 23, No. I mass flow meter 24, No. II mass flow meter 25, back pressure valve 26; The auxiliary circulation system includes No. II water tank 27 , No. III filter 28 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com