Method for testing liquid lubrication machine seal sealing performance and devices thereof

A mechanical seal and testing method technology, which is applied in the direction of liquid tightness measurement by using liquid/vacuum degree, and by measuring the increase and decrease rate of the fluid, can solve the problems of difficult friction torque, centering difficulty, and large vibration of the sealing end face. Achieve the effect of convenient adjustment and overcoming large vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1 A kind of testing method of liquid lubricated mechanical seal sealing performance, comprises the following steps:

[0032] 1) Add sealing medium to the liquid storage tank, start the compressor to supply pressure to the sealing pressure, start the circulation pump to realize the circulation of the sealing medium in the sealing cavity, and the pressure of the sealing medium is controlled by the compressor;

[0033] 2) Measure the temperature of the end face: start the motor, the motor drives the moving components to rotate, insert a thermocouple sensor into the test hole on the static seal ring of the experiment, the thermocouple sensor transmits the real-time monitored temperature signal to the computer, and the computer performs the temperature signal received. Analysis and processing;

[0034] 3) Leakage rate measurement: Under the action of the pressure difference on the end face of the mechanical seal, the sealing medium will leak to the outside through...

Embodiment 2

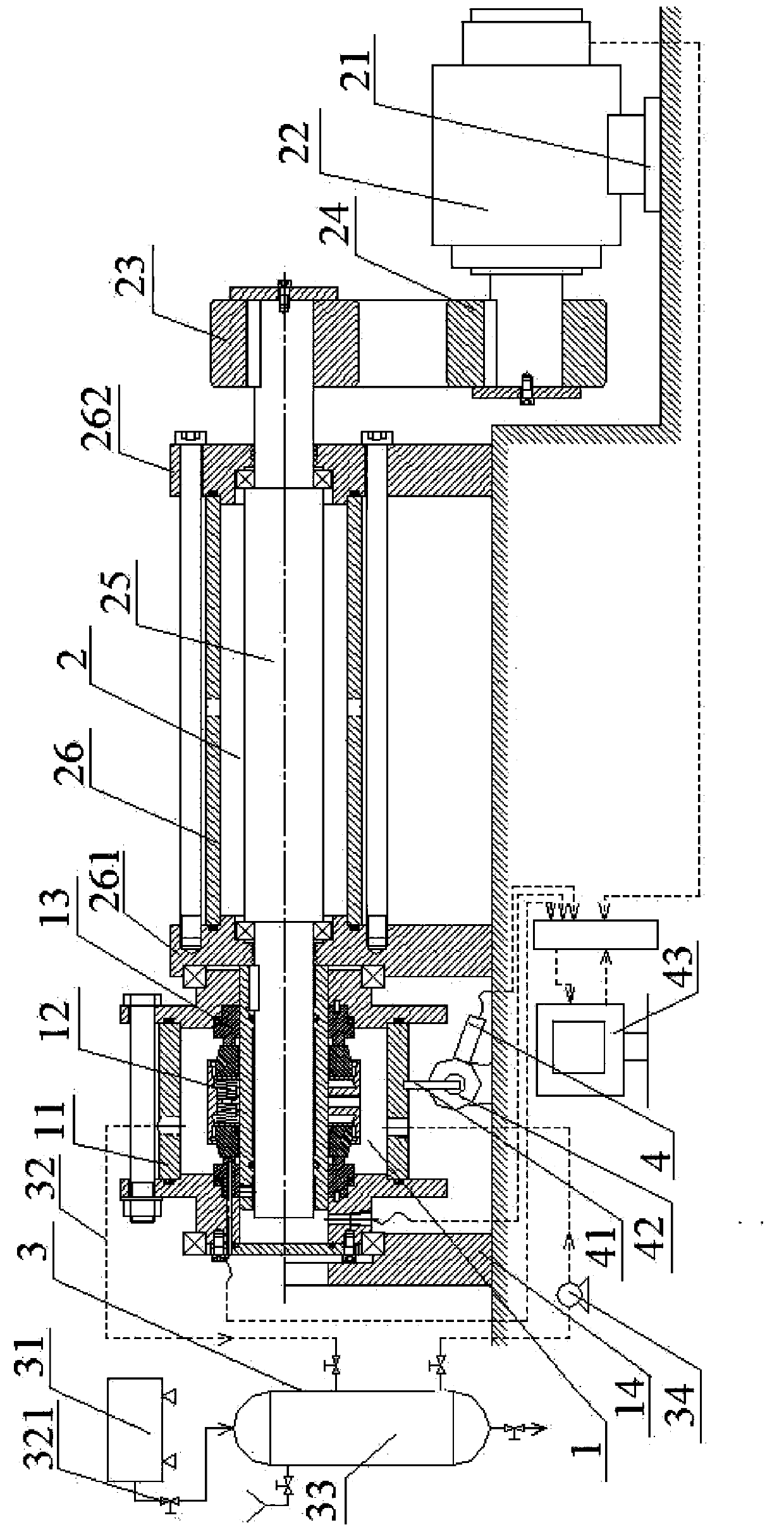

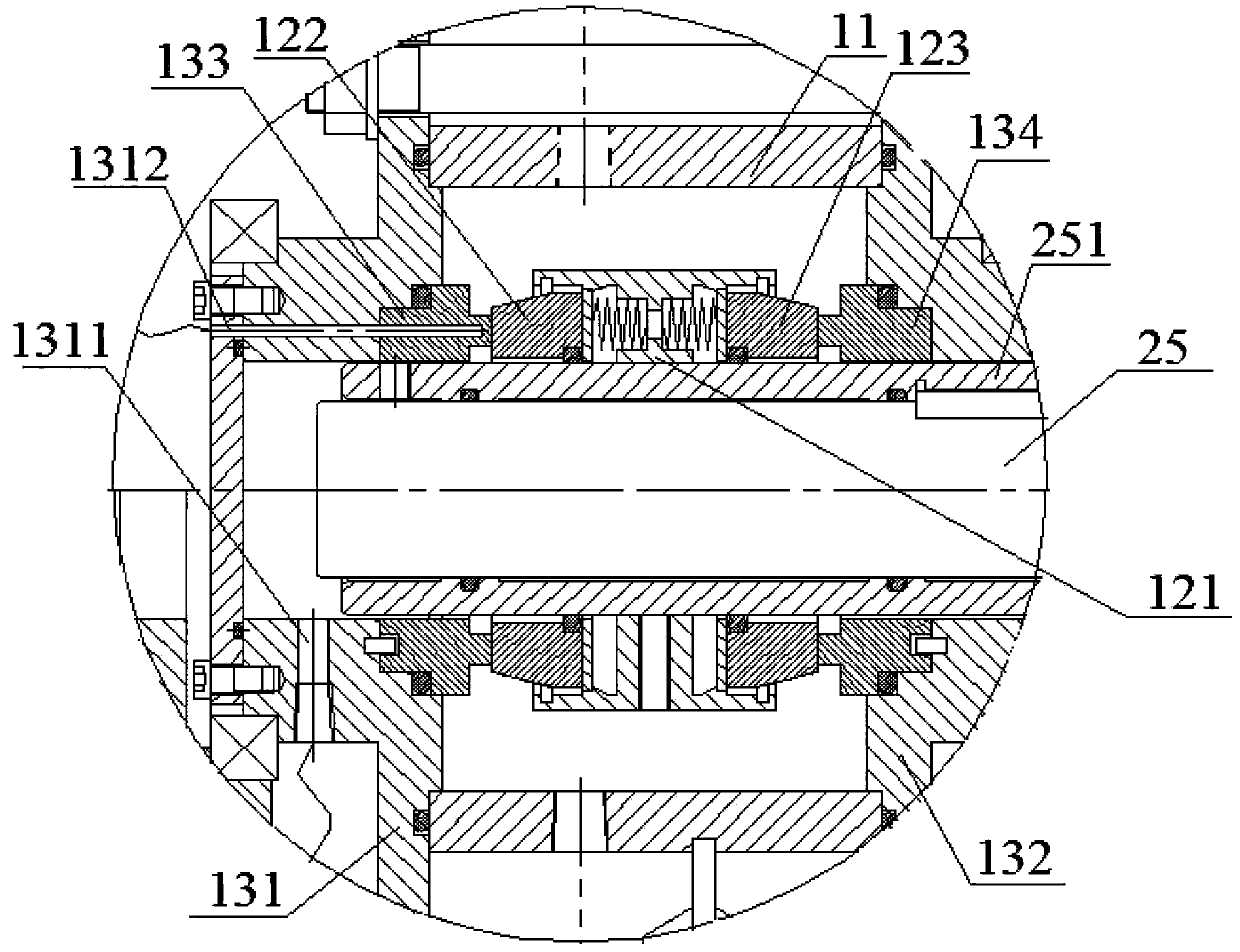

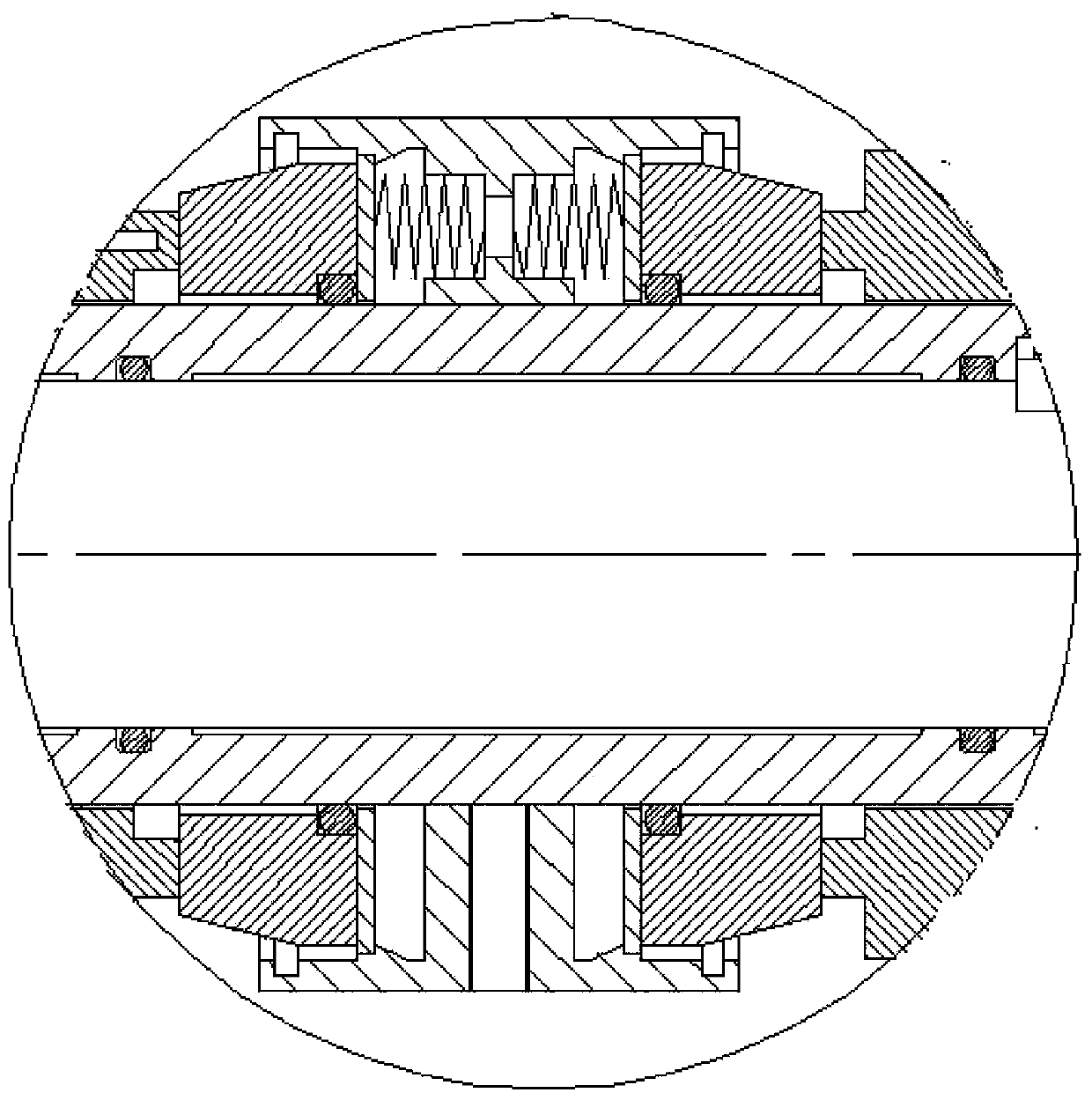

[0038]Embodiment 2 The device constructed according to the test method described in Embodiment 1 includes a sealing device 1, a driving device 2, an auxiliary device 3, and a testing device 4. The sealing device 1 includes a sealed cavity with a sealing liquid inlet and outlet 11. The moving assembly 12 and the static assembly 13 installed in the sealed cavity, the moving assembly 12 includes the moving ring seat 121, the experimental sealing moving ring 122, the auxiliary sealing moving ring 123, the experimental sealing moving ring 122, the auxiliary sealing The sealing dynamic ring 123 is installed on the shaft sleeve 251 of the rotating shaft 25; the static assembly 13 includes a static ring end cover 131, an auxiliary static ring end cover 132, an experimental sealing static ring 133 and an auxiliary sealing static ring 134. The sealing static ring 133 and the auxiliary sealing static ring 134 are respectively fixed with the static ring end caps 131 and the auxiliary stati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com