Cryogenic fixed ball valve

A fixed ball valve, low temperature technology, applied to the valve details, valve device, valve shell structure, etc., can solve the problems of poor effect, easy leakage, valve sealing effect, etc., to achieve simple structure, timely pressure relief, and good sealing effect leaked effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

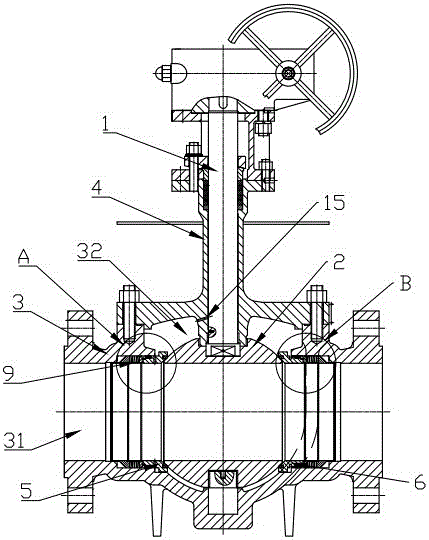

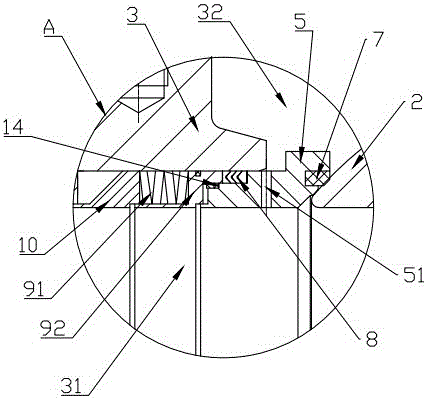

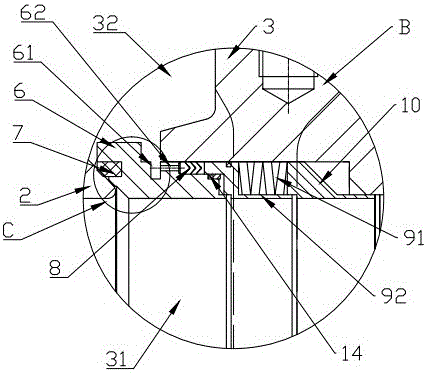

[0027] like figure 1 , figure 2 and image 3 As shown, a low-temperature fixed ball valve includes a valve body 3, a ball body 2, a valve stem 1, and a valve cover 4. The valve body 3 is provided with a flow channel 31, and the ball body 2 is arranged in the flow channel 31 of the valve body 3. , linked with the valve stem 1; the two sides of the sphere 2 are provided with a valve seat support ring, a valve seat 7 is provided between the valve seat support ring and the sphere 2, and a valve seat 7 is provided between the valve seat support ring and the valve body 3 There is a sealing component 8; the valve seat support ring, the valve seat 7, the valve cover 4, the valve body 3 and the outer ring of the ball 2 constitute the valve body cavity 32;

[0028] The first valve seat support ring 5 on one side of the ball 2 is provided with a pressure relief hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com