Explosion-proof PCB

A kind of PCB board, explosion-proof technology, applied in printed circuit components, circuit thermal devices, printed circuit stress/deformation reduction and other directions, can solve problems such as damage and explosion of PCB boards, prolong service life, reduce production costs, and prevent deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The embodiment of the invention discloses an explosion-proof PCB board,

[0027] Specifically include:

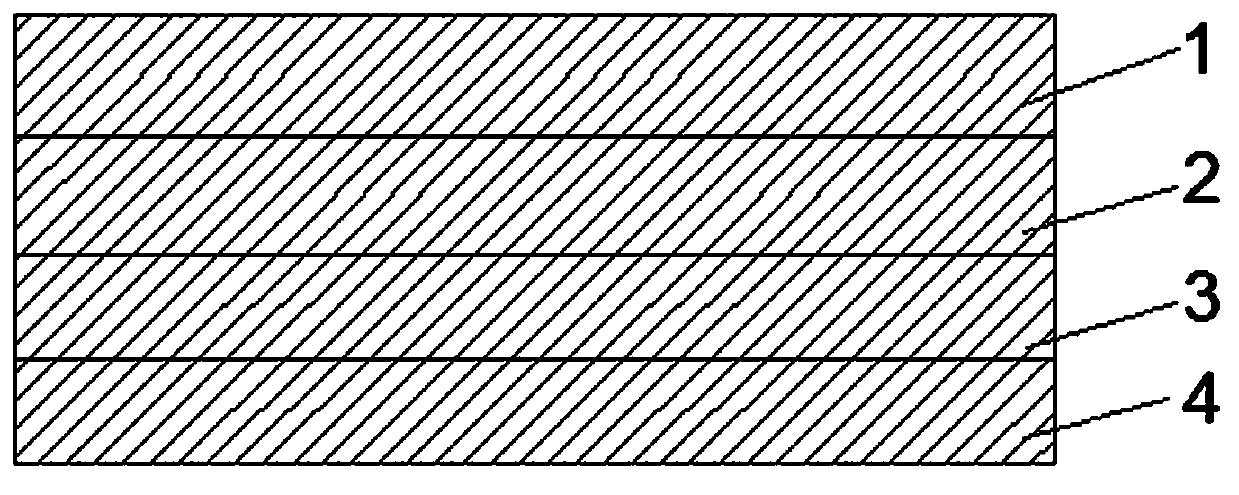

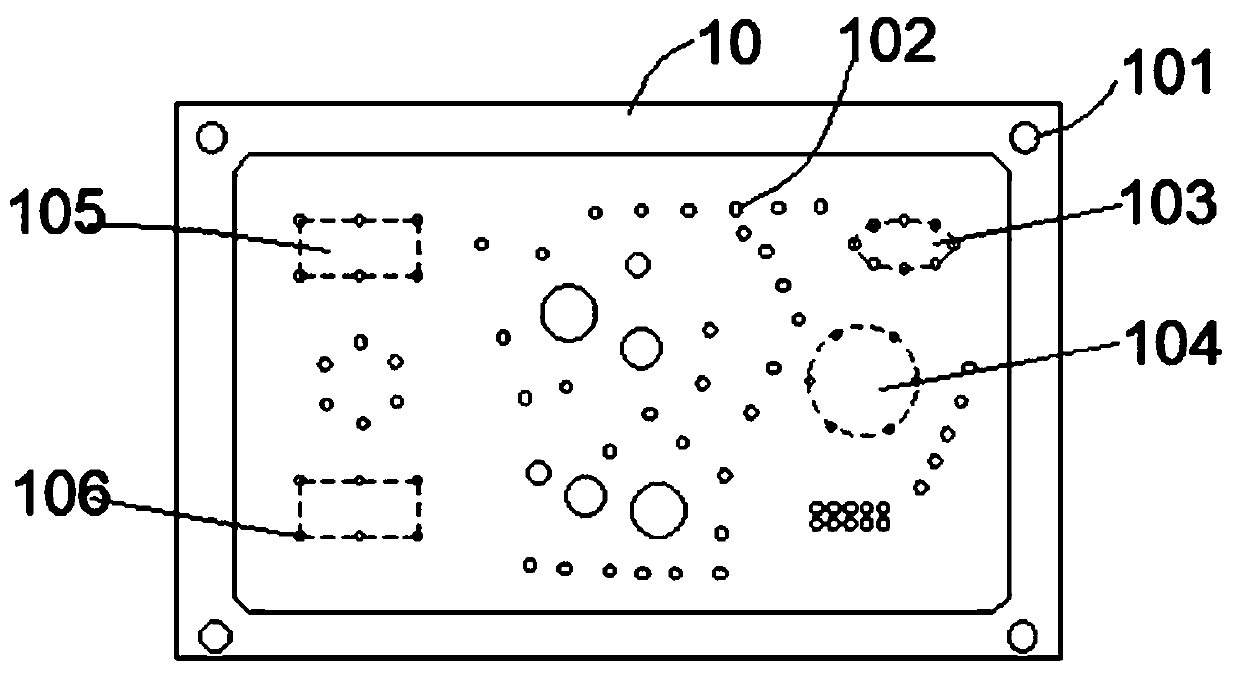

[0028] see figure 1 , figure 2 , an explosion-proof PCB board, including a top board 1, a wire layer 2, a signal layer 3 and a bottom board 4 connected in sequence, the top board 1, the wire layer 2, the signal layer 3 and the bottom board 4 have the same structure, each The layers are bonded with an insulating bonding material, and the top layer board 1 is a PCB substrate 10;

[0029] The PCB substrate 10 includes a mounting hole 101, a circuit connection pad 102, an oval mounting area 103, a circular mounting area 104, a rectangular mounting area 105 and an explosion-proof hole 106;

[0030] The bottom of the bottom plate 4 is provided with a layer of natural graphite heat dissipation film.

[0031] The explosion-proof PCB board is formed by laminating a top layer board 1 , a wire layer 2 , a signal layer 3 and a bottom board 4 .

[0032] The PCB substrate 10...

Embodiment 2

[0043] The embodiment of the invention discloses an explosion-proof PCB board,

[0044] Specifically include:

[0045] see figure 1 , figure 2 , an explosion-proof PCB board, including a top board 1, a wire layer 2, a signal layer 3 and a bottom board 4 connected in sequence, the top board 1, the wire layer 2, the signal layer 3 and the bottom board 4 have the same structure, each The layers are bonded with an insulating bonding material, and the top layer board 1 is a PCB substrate 10;

[0046] The PCB substrate 10 includes a mounting hole 101, a circuit connection pad 102, an oval mounting area 103, a circular mounting area 104, a rectangular mounting area 105 and an explosion-proof hole 106;

[0047] The bottom of the bottom plate 4 is provided with a layer of artificial graphite heat dissipation film.

[0048] The explosion-proof PCB board is formed by laminating a top layer board 1 , a wire layer 2 , a signal layer 3 and a bottom board 4 .

[0049] The PCB substrate...

Embodiment 3

[0060] The embodiment of the invention discloses an explosion-proof PCB board,

[0061] Specifically include:

[0062] see figure 1 , figure 2 , an explosion-proof PCB board, including a top board 1, a wire layer 2, a signal layer 3 and a bottom board 4 connected in sequence, the top board 1, the wire layer 2, the signal layer 3 and the bottom board 4 have the same structure, each The layers are bonded with an insulating bonding material, and the top layer board 1 is a PCB substrate 10;

[0063] The PCB substrate 10 includes a mounting hole 101, a circuit connection pad 102, an oval mounting area 103, a circular mounting area 104, a rectangular mounting area 105 and an explosion-proof hole 106;

[0064] A layer of nano-carbon heat dissipation film is provided on the bottom of the bottom plate 4 .

[0065] The explosion-proof PCB board is formed by laminating a top layer board 1 , a wire layer 2 , a signal layer 3 and a bottom board 4 .

[0066] The PCB substrate 10 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com