Muffler assembly with siphon tube

A siphon tube and component technology, applied in the field of muffler components, can solve problems such as increased noise, discoloration of parking areas, increased weight or cost, etc., to achieve the effects of worsening noise problems, less corrosion, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

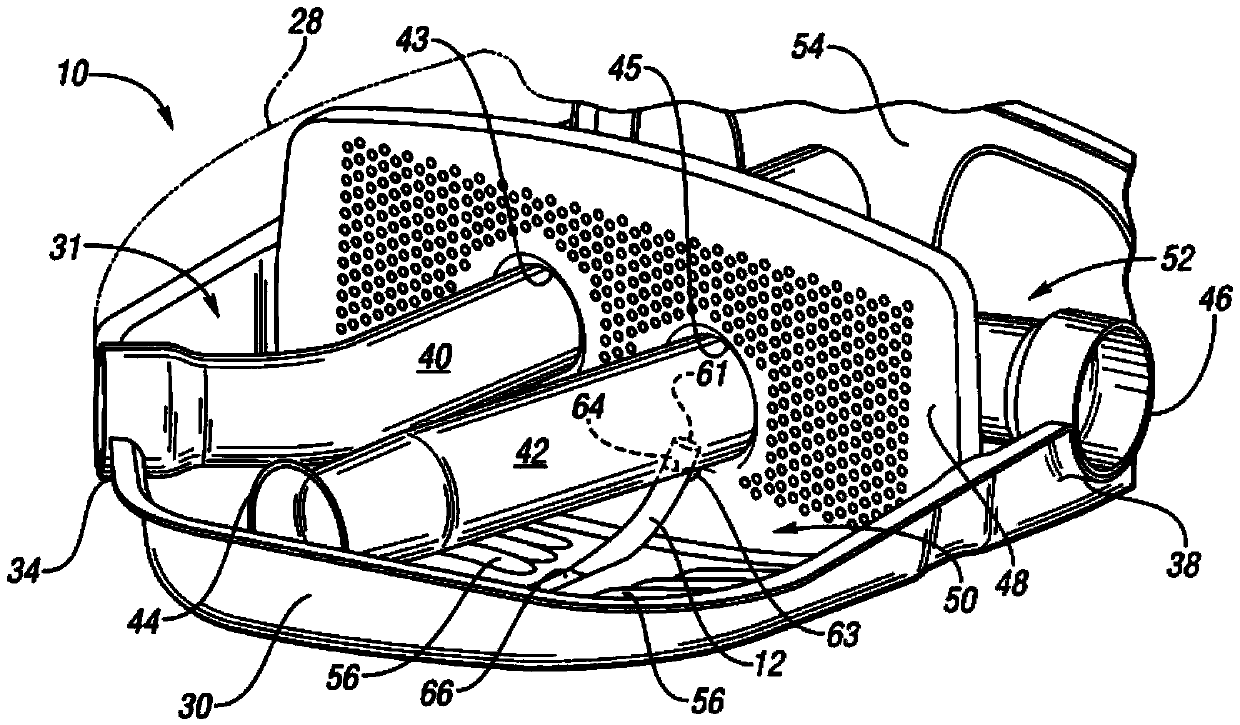

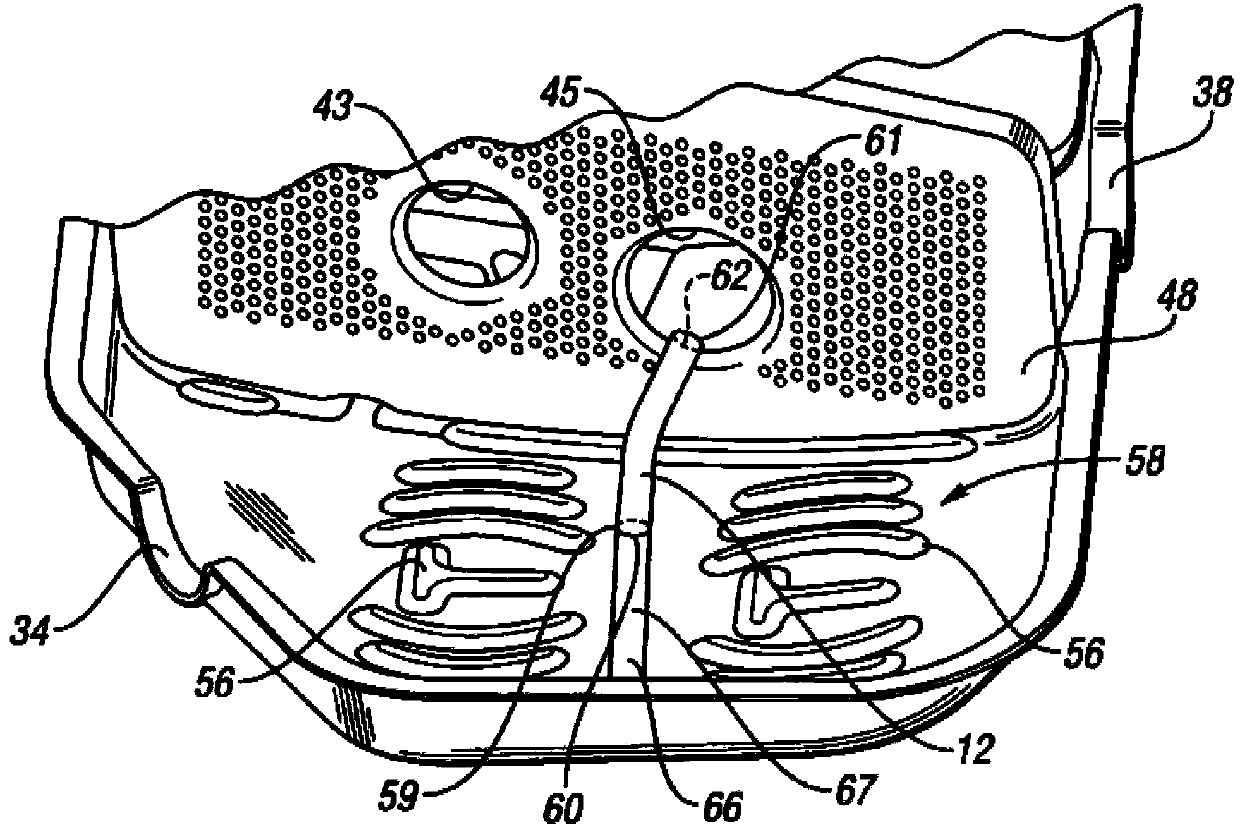

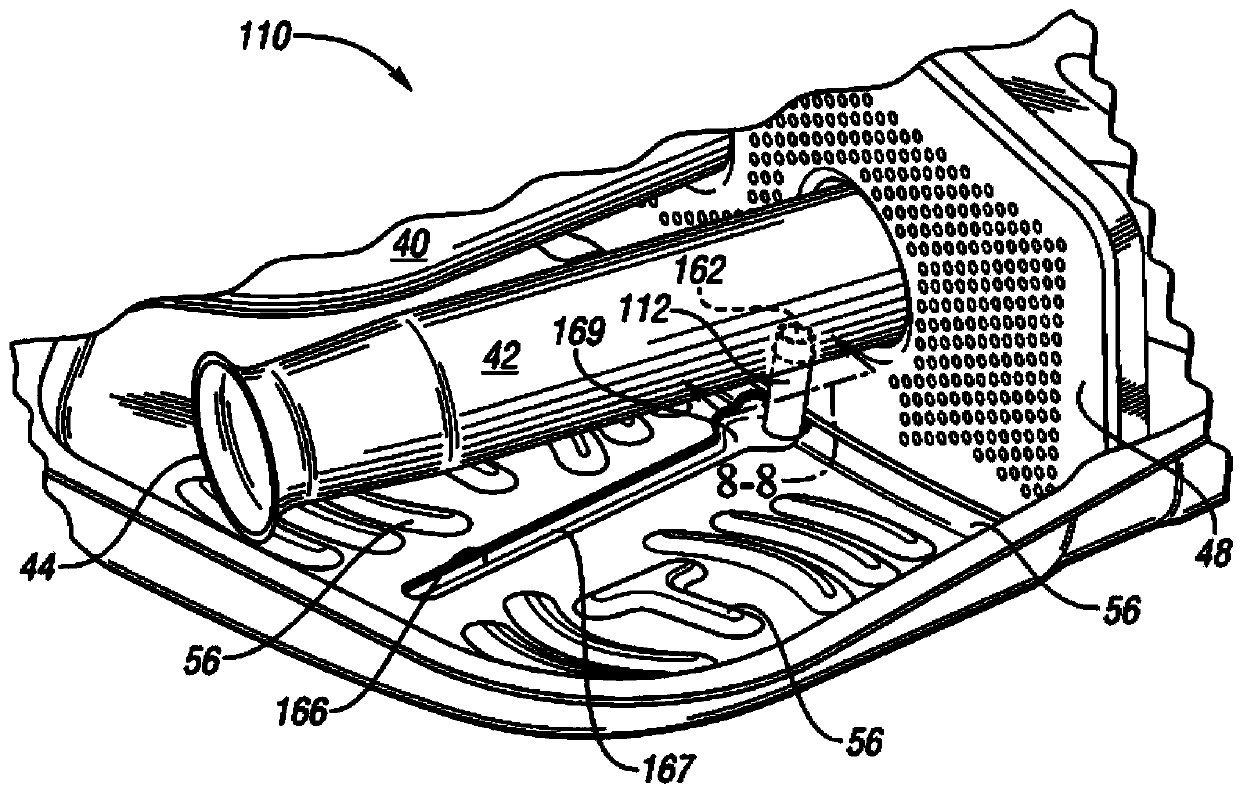

[0014] Referring to the drawings, wherein like reference numerals represent like parts throughout the several views, figure 1 A muffler assembly 10 is shown having a siphon 12 specifically designed to remove condensate from the muffler assembly 10 as further described herein. Specifically, the muffler assembly 10 is designed such that condensate collects below the siphon tube and is discharged from the muffler assembly 10 through the siphon tube 12 when the pressure differential across the siphon tube 12 reaches a predetermined level.

[0015] The muffler assembly 10 is part of an exhaust system 14 of a vehicle 16, such as Figure 5 shown. The vehicle 16 has front wheels 18 and rear wheels 20 . The powertrain 22 includes an engine 24 operatively connected to the front wheels 18 through a transmission 26 for propelling the vehicle. Exhaust system 14 extends from engine 24 to treat engine exhaust prior to expelling the exhaust to the atmosphere. One or more exhaust treatment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com