Large-section water-rich saturated fine sand railway tunnel excavation method

A technology for tunnel excavation and silty sand, which is applied in tunnels, tunnel linings, drainage, etc., can solve the problems of poor self-stability of silty sand, deterioration in contact with water, and outflow of quicksand, so as to improve construction quality and reduce Construction errors and the effect of ensuring construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

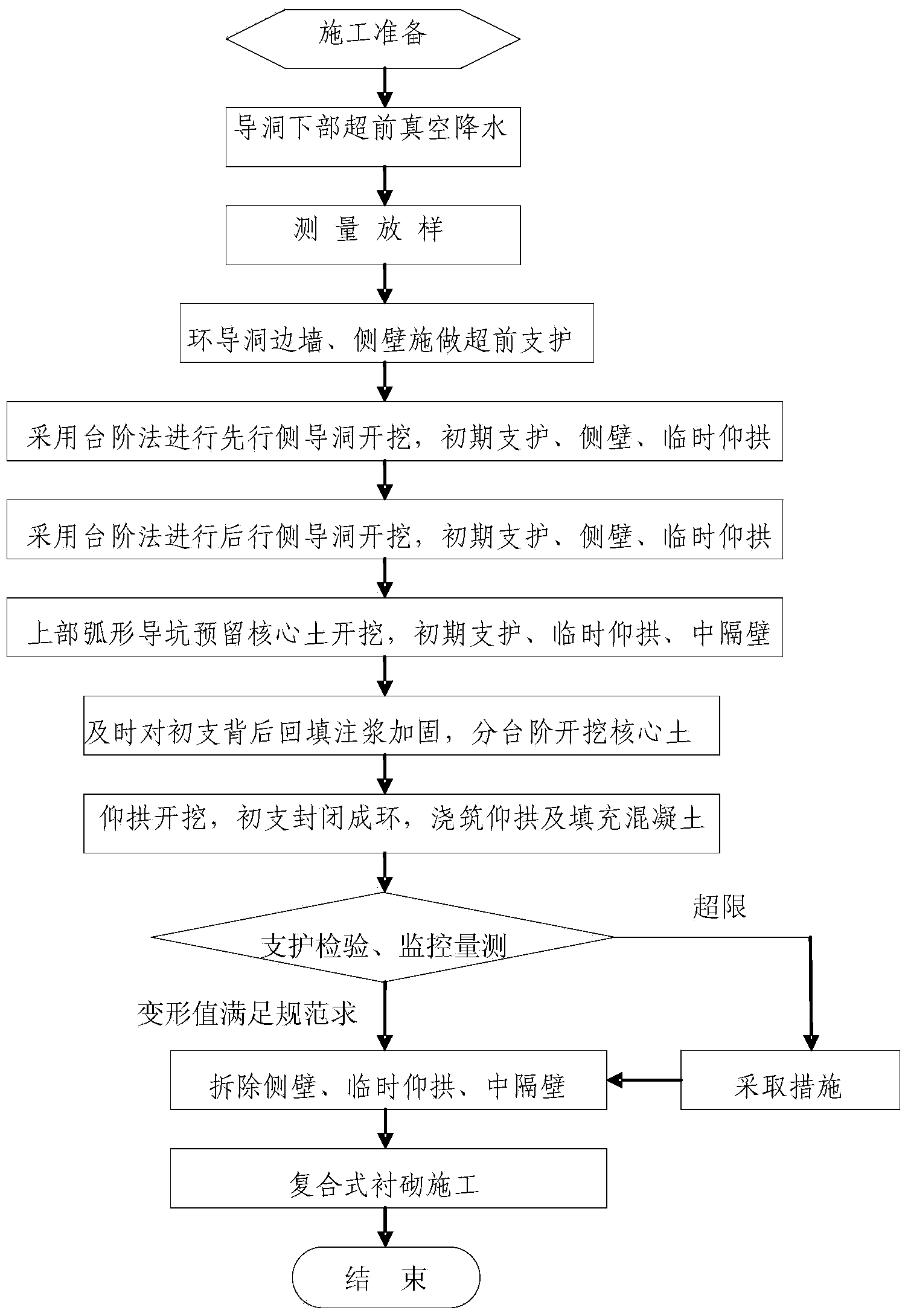

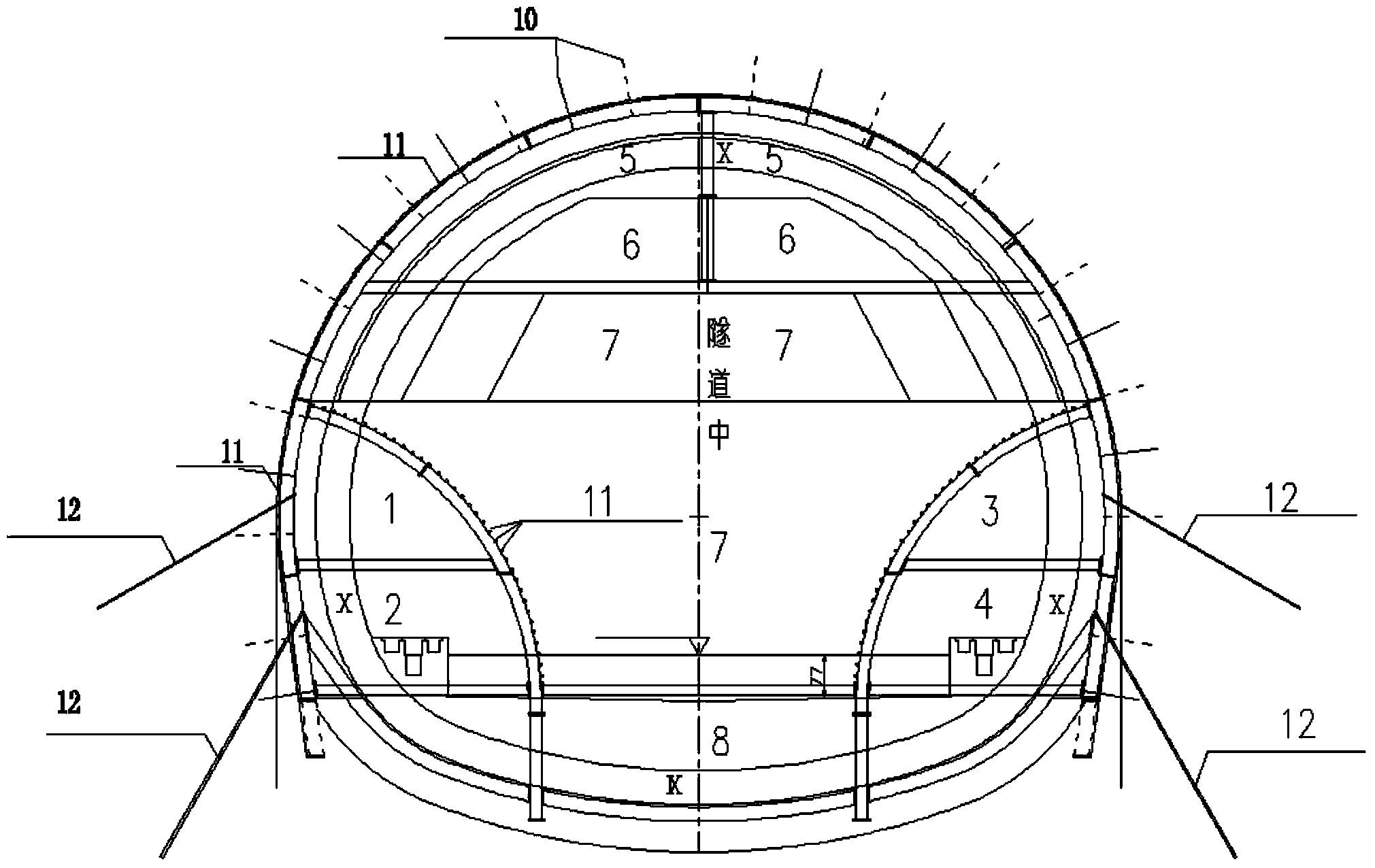

[0026] A method for excavating a large-section water-rich saturated silty sand railway tunnel, comprising the following steps:

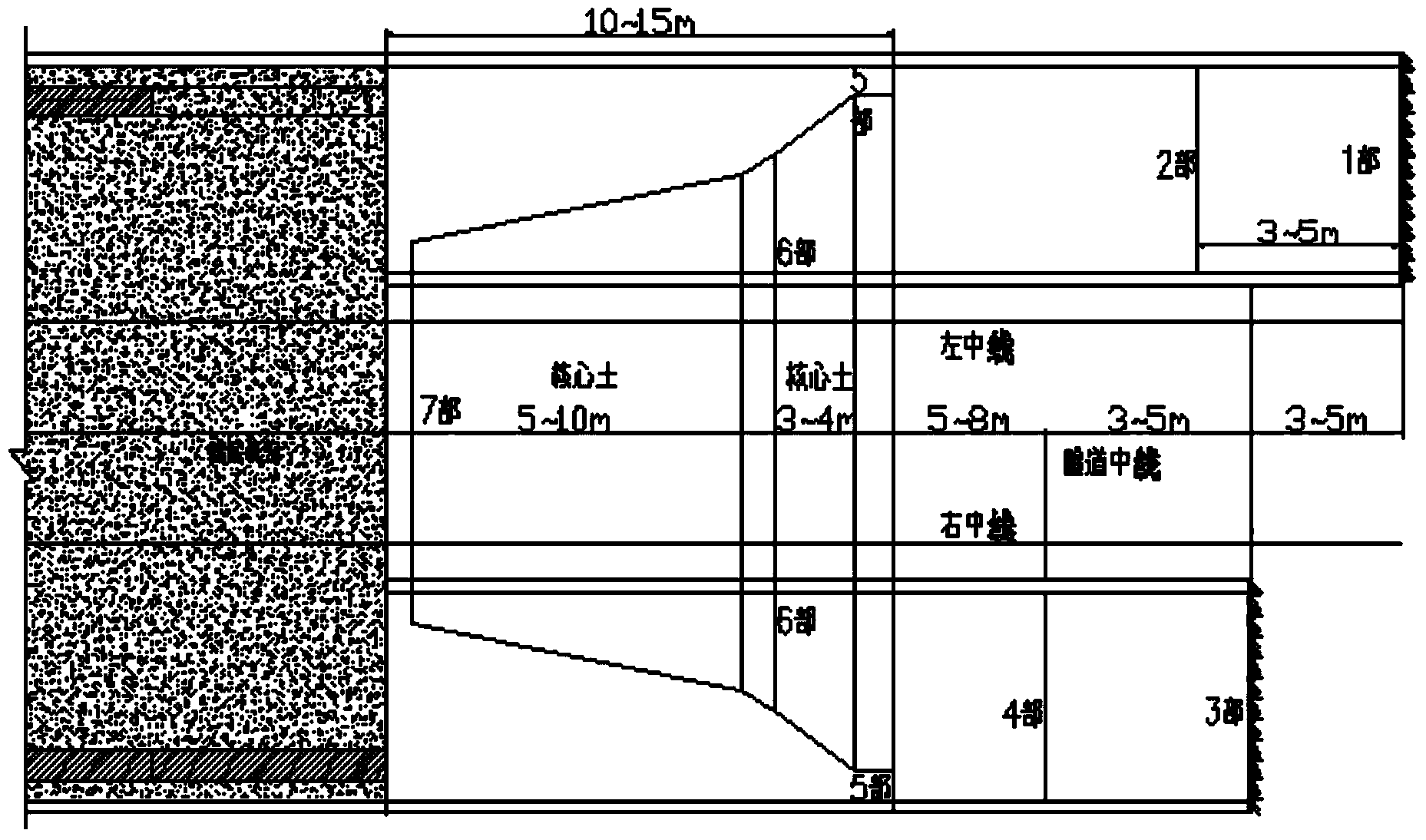

[0027] 1. A double-side-wall pilot tunnel is constructed ahead of time in the lower half of the main tunnel. The pilot tunnel is excavated in steps, and temporary inverted arches are set up separately, and the sections are closed to form a ring. The specific steps are:

[0028] 1. (1) Use the steel frame erected in the previous circulation to implement the advance support of the tunnel; (2) Excavate a part of the soil; (3) Implement the initial support and temporary support in time, and set up temporary inverted arches Closed into a loop, the steel frame lock foot anchor pipe is installed.

[0029] 2. After the first part is constructed to an appropriate distance, the second part is excavated, the steel frame is extended, and the initial support, side wall and bottom temporary inverted arch are applied to make it closed into a ring.

[0030] 3. As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com