Combined process for preparing fuel oil by hydro-cracking and hydro-upgrading of coal tar

A hydrogenation upgrading and combined process technology, applied in the field of coal chemical industry, can solve the problems of no further utilization of heavy components, low utilization of raw materials, low utilization rate of coal tar, etc., to improve product quality and reduce coke yield , The effect of reducing the incidence of coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1~3

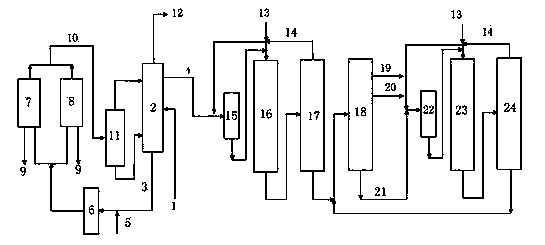

[0018] The embodiment of this solution is described in conjunction with the flow chart of the device to further illustrate the present invention.

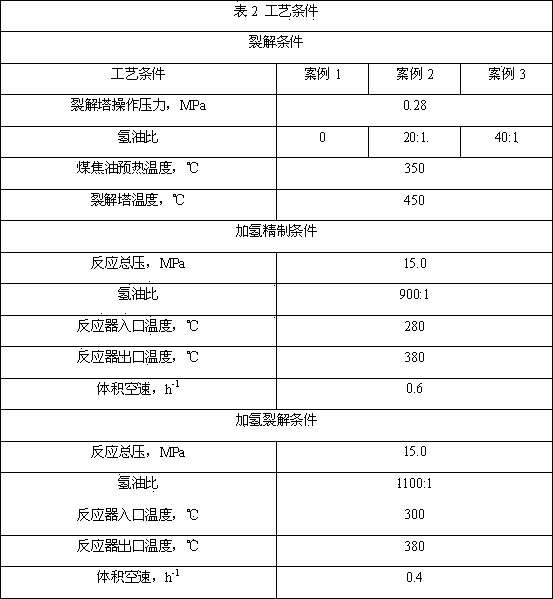

[0019] combine figure 1The coal tar raw material 1 is put into the cracking and fractionating tower 2, and the heavy component oil 3 with a temperature greater than 360°C is fractionated and sent to the cracking heating furnace 6 for recycling, and the light component oil 4 with a fractional distillation temperature lower than 360°C is sent to the hydrofining process, The heavy component oil 3 preheated to 320-420°C is mixed with hydrogen 5 and sent to the cracking heating furnace 6, heated to 400-480°C and entered into the hydrogen cracking towers 7 and 8 for cracking reaction. During operation, the reaction pressure of the cracking tower is controlled to 0.28MPa, and the temperature is controlled at 450~550°C. The ratio of hydrogen to oil is controlled as follows: Case 1 is 0; Case 2 is 20:1; Case 3 is 40:1. The two hydrocracki...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com