Preparation method of polymer flooding produced fluid demulsifier

A technology of demulsifier and polymer, which is applied in the field of preparation of high-efficiency and fast polymer flooding production fluid demulsifier, which can solve the problem of low dehydration rate of polymer flooding production fluid, low demulsification speed of demulsifier, slow dehydration speed, etc. problem, to achieve high yield of demulsifier, reduce dehydration cost and high dehydration rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

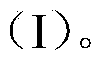

Examples

Embodiment 1

[0042] A preparation method for polymer flooding production fluid demulsifier, the steps are as follows:

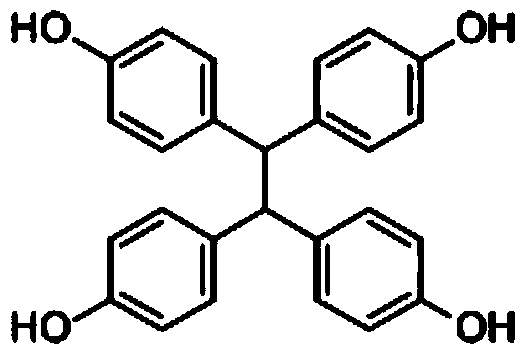

[0043] (1) Synthesis of tetraphenol ethane type phenolic amine resin starter:

[0044] Add 76g of tetraethylenepentamine to a 250ml three-necked flask, raise the temperature to 120°C and add 40g of tetraphenolyl ethane with stirring, after stirring and dissolving completely, cool down to 37°C, add dropwise 80g of 38wt% formaldehyde solution at a rate of 5g / min, and react After 2 hours, add 70 g of xylene, then raise the temperature to 100° C., dehydration reaction for 4 hours, and remove the xylene by distillation under reduced pressure to obtain a tetraphenol ethane type phenolamine resin initiator;

[0045] (2) Synthesis of lipophilic head of demulsifier:

[0046] Take 10g of tetraphenol-based ethane type phenolamine resin starter obtained in step (1) and put 2g of potassium hydroxide into the autoclave, after sealing the autoclave, start stirring and raise the tempera...

Embodiment 2

[0050] A preparation method for polymer flooding production fluid demulsifier, the steps are as follows:

[0051] (1) Synthesis of tetraphenol ethane type phenolic amine resin starter:

[0052] Step is with embodiment 1;

[0053] (2) Synthesis of lipophilic head of demulsifier:

[0054]Take 10g of the tetraphenol-based ethane type phenolamine resin starter obtained in step (1) and put 2g of sodium hydroxide into the autoclave, after sealing the autoclave, start stirring and raise the temperature, exhaust nitrogen 3 times, wait until the temperature rises When it reaches 80°C, use a vacuum pump to evacuate the autoclave until it reaches -0.1MPa, and stop vacuuming after 30 minutes; when the temperature rises to 130°C, slowly add 690g of propylene oxide, keep the pressure at 0.4MPa, and react for 10h to prepare Demulsifier lipophilic head;

[0055] (3) Synthesis of demulsifier for polymer flooding production fluid:

[0056] Take 60g of the lipophilic head of the demulsifier ...

Embodiment 3

[0058] A preparation method for polymer flooding production fluid demulsifier, the steps are as follows:

[0059] (1) Synthesis of tetraphenol ethane type phenolic amine resin starter:

[0060] Step is with embodiment 1;

[0061] (2) Synthesis of lipophilic head of demulsifier:

[0062] Take 10g of the tetraphenol-based ethane type phenolamine resin starter obtained in step (1) and put 3g of potassium hydroxide into the autoclave, after sealing the autoclave, start stirring and raise the temperature, exhaust nitrogen gas 3 times, wait until the temperature rises When it reaches 80°C, use a vacuum pump to evacuate the autoclave until it reaches -0.1MPa, and stop vacuuming after 30 minutes; when the temperature rises to 120°C, slowly add 990g of propylene oxide, keep the pressure at 0.4MPa, and react for 10h to prepare Demulsifier lipophilic head;

[0063] (3) Synthesis of demulsifier for polymer flooding production fluid:

[0064] Take 60g of the lipophilic head of the demu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com