A kind of preparation method of waterborne acrylic polyurethane matting resin with phase separation structure

A technology of acrylic polyurethane and matting resin, applied in the coating and other directions, can solve the problems of the coating being easily affected by the solvent, insufficient masking of mold scars, increased energy consumption, etc., and achieve excellent masking of mold marks, improve mechanical strength and surface Scratch resistance, the effect of a wide range of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

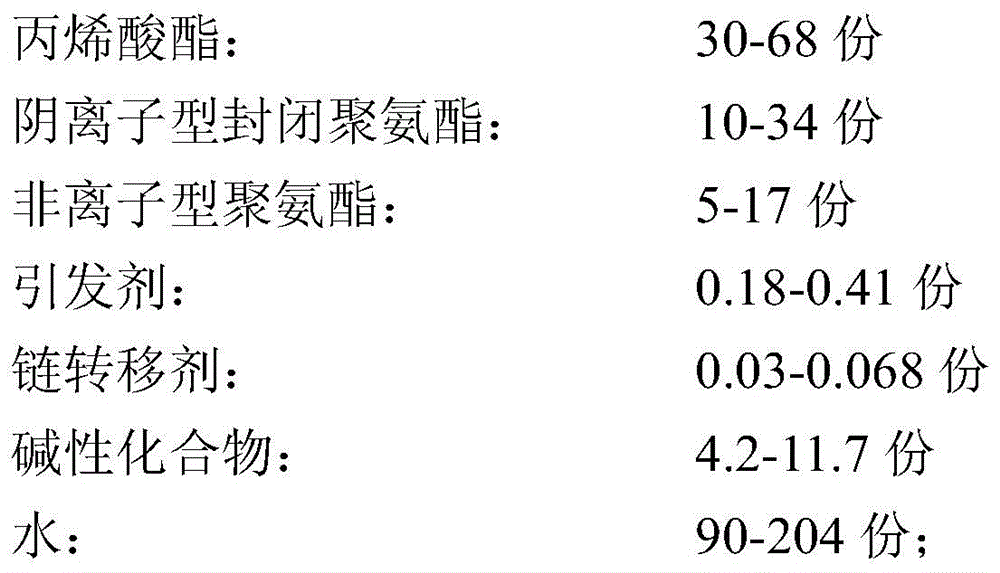

Method used

Image

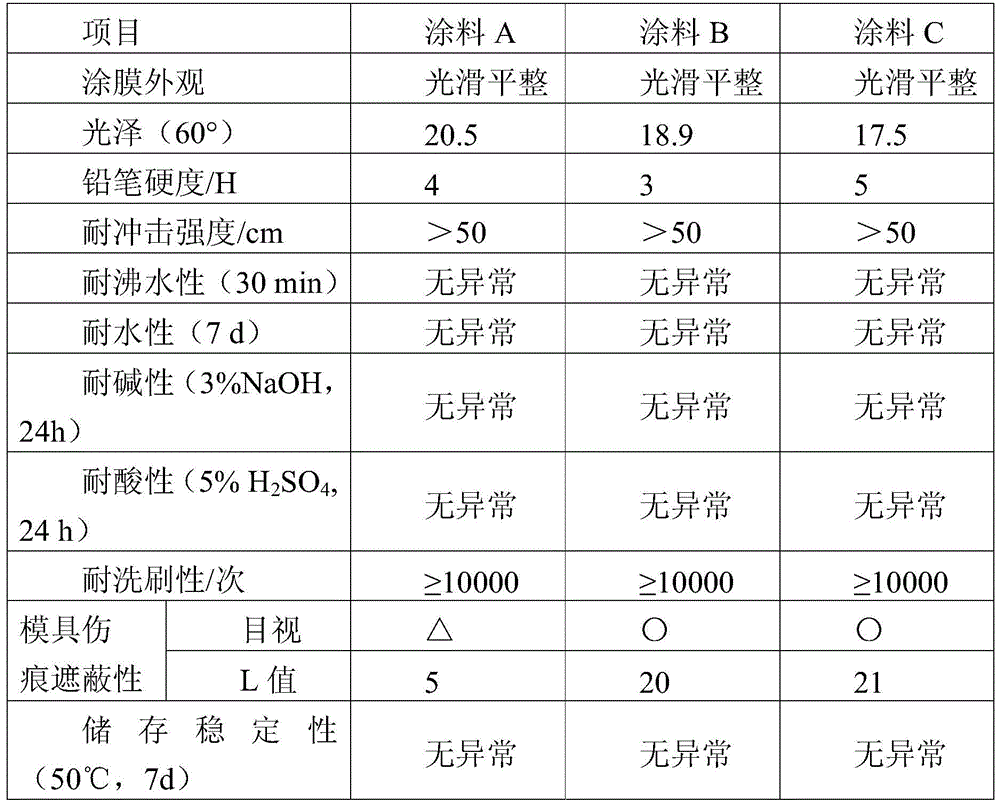

Examples

Embodiment 1

[0046] A preparation method of acrylic polyurethane matting resin with phase separation structure, comprising the following steps:

[0047] (1) Preparation of anionic blocked polyurethane: mix 0.10mol isophorone diisocyanate with 0.025mol polyethylene glycol (molecular weight 400), add 1-2 drops of catalyst dibutyltin laurate, 50ml acetone, stir well, Reflux reaction in a constant temperature water bath at 80°C for 1.5h, add 0.0125mol 1,4-butanediol to continue the reaction for 1h while stirring, then add 0.0525mol dimethylol propionic acid to continue the reaction for 4h, add 0.8mol methyl ethyl ketone oxime to continue the reflux reaction for 2h, When it is determined that there is no free -NCO in the product by the dibutylamine method, cool down to 60°C, add 0.0525mol triethylamine to continue the reaction for 0.5h, add distilled water under high-speed stirring, vigorously shear and stir for 0.5h, cool down, Extract acetone to obtain anionic blocked polyurethane;

[0048] ...

Embodiment 2

[0053] A preparation method of acrylic polyurethane matting resin with phase separation structure, comprising the following steps:

[0054] (1) The preparation method of anionic polyurethane is the same as the step (1) of Example 1;

[0055] (2) Preparation of non-ionic polyurethane: add 0.05mol HDI trimer and 0.15mol polyethylene glycol monomethyl ether (molecular weight 1000), 1-2 drops of catalyst dibutyltin laurate, 50ml acetone into the reactor, stir Evenly, reflux reaction in a constant temperature water bath at 80°C for 5 hours, and when the product does not contain free -NCO by the dibutylamine method, add distilled water under high-speed stirring, vigorously shear and stir for 0.5 hours, cool down and remove acetone, and prepare Obtain non-ionic polyurethane;

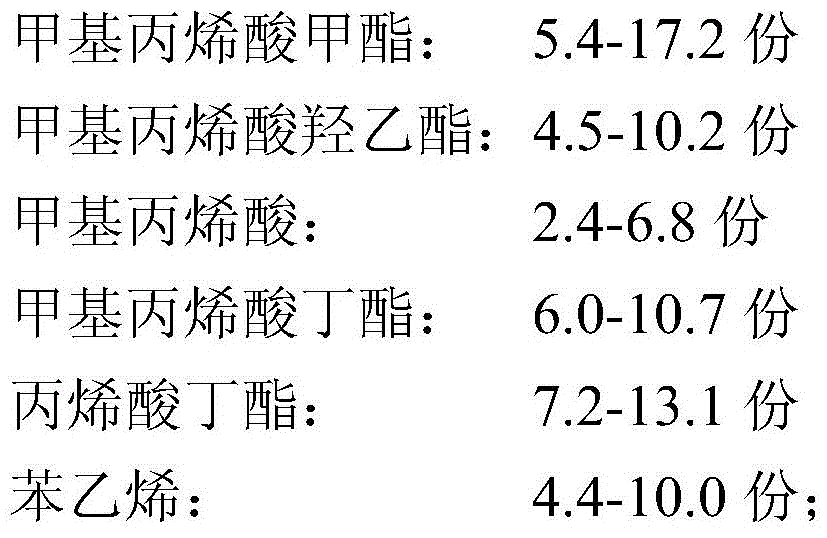

[0056] (3) Mix 12 parts of methyl methacrylate, 7.5 parts of hydroxyethyl methacrylate, 5.0 parts of methacrylic acid, 7.7 parts of butyl methacrylate, 10.2 parts of butyl acrylate, and 7.6 parts of styrene to...

Embodiment 3

[0060] A preparation method of acrylic polyurethane matting resin with phase separation structure, comprising the following steps:

[0061] (1) Preparation of anionic blocked polyurethane: mix 0.10mol isophorone diisocyanate with 0.025mol polyethylene glycol (molecular weight 1000), add 1-2 drops of catalyst dibutyltin laurate, 50ml acetone, stir well, Reflux reaction in a constant temperature water bath at 80°C for 1.5h, add 0.0125mol 1,4-butanediol to continue the reaction for 1h while stirring, then add 0.0525mol dimethylolpropionic acid to continue the reaction for 4h, add 0.8mol methyl ethyl ketone oxime to continue the reflux reaction for 2h, When it is determined that there is no free -NCO in the product by the dibutylamine method, cool down to 60°C, add 0.0525mol triethylamine to continue the reaction for 0.5h, add distilled water under high-speed stirring, vigorously shear and stir for 0.5h, and cool down. Extract acetone to obtain anionic blocked polyurethane;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com