Straightening mechanism of ceramic tile stack

A ceramic tile and rack technology, applied in the field of tile stack up and down straightening mechanism, can solve the problems of high manufacturing cost, slow working rhythm, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with specific embodiment:

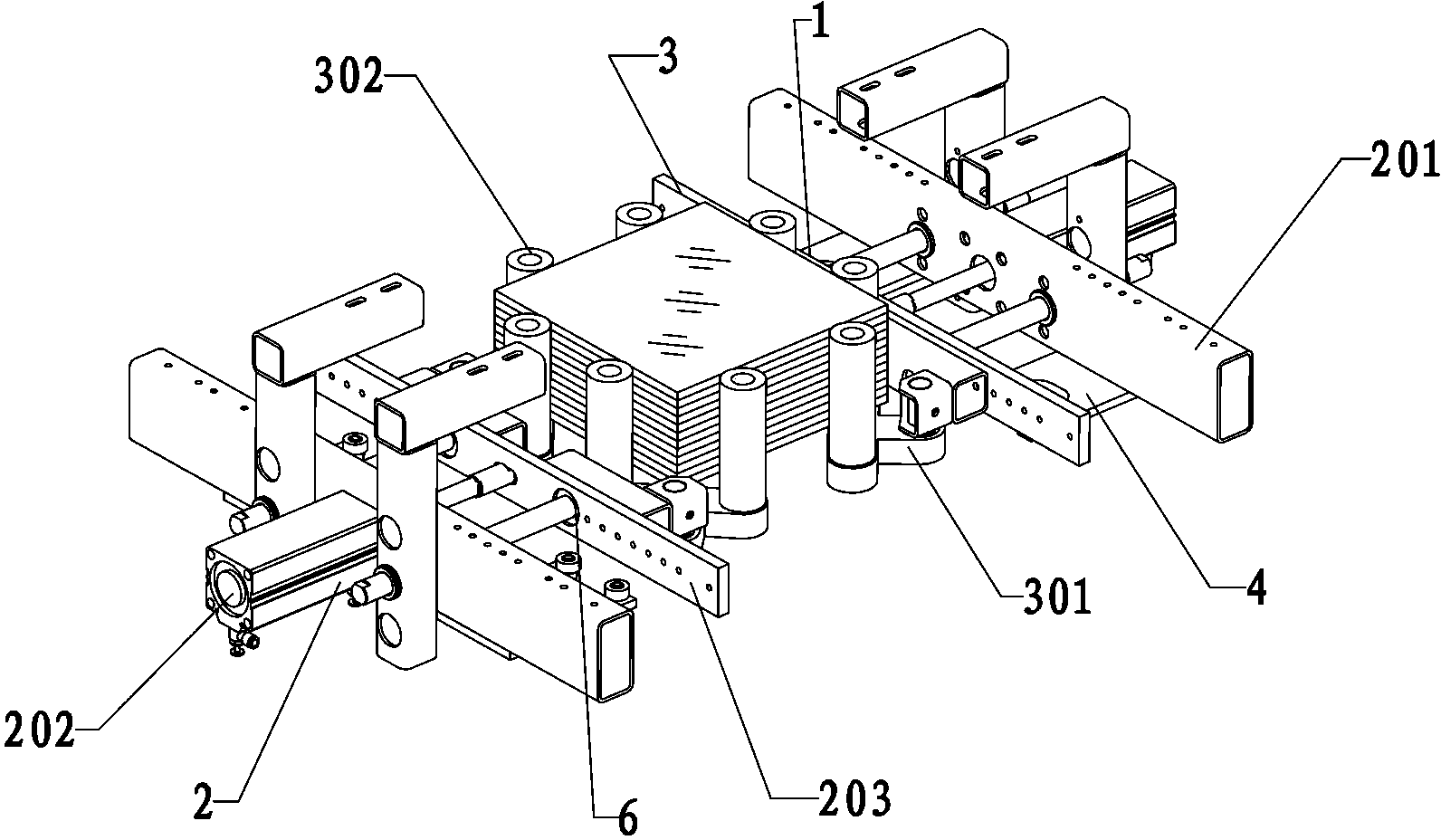

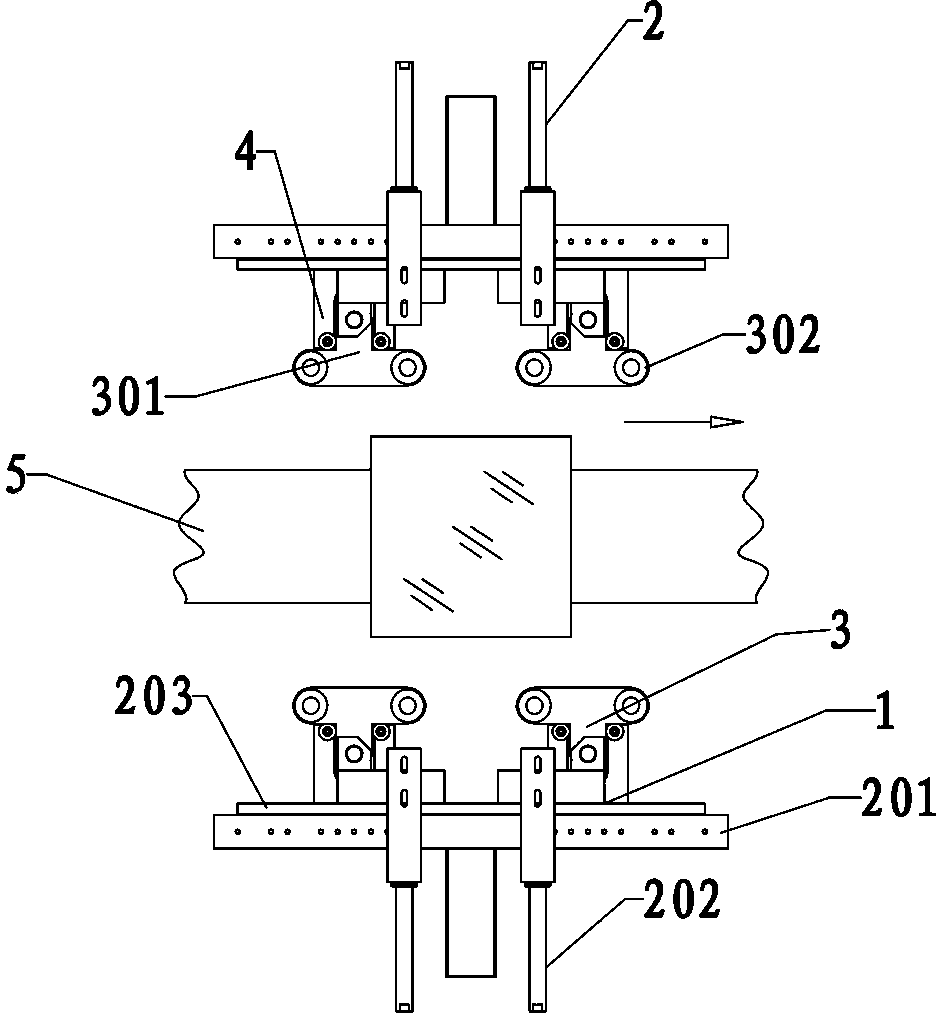

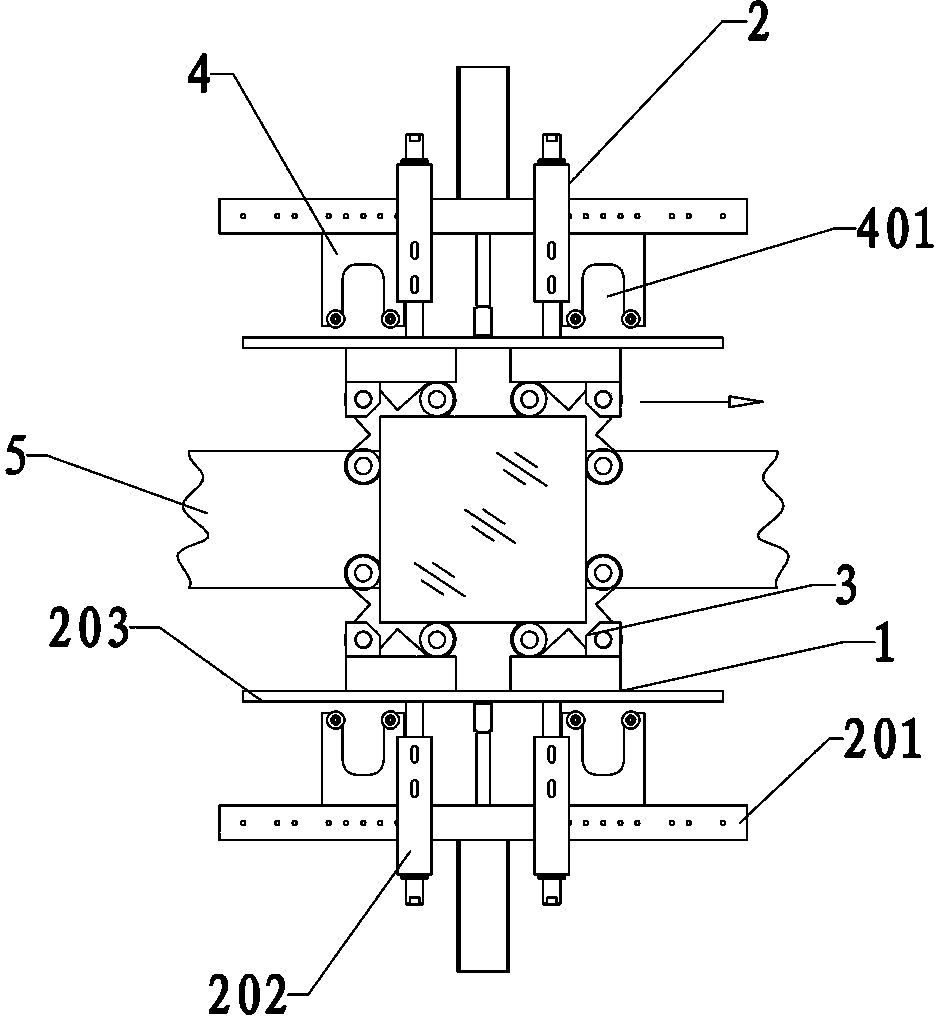

[0013] See attached Figure 1 to Figure 3 As shown, a tile stack straightening mechanism described in this embodiment includes a frame, a tile stack conveyor line 5 installed on the frame, and a pair of mirror-symmetrical tiles located on both sides of the conveyor line 5, respectively. Pushing alignment components 1, wherein each pushing alignment assembly 1 includes a pushing alignment driving device 2 and a straight stick assembly 3. The pushing device 2 includes a cylinder block 201, a moving cylinder 202 fixed on the cylinder block 201 and a sliding guide pair 6, and a pushing beam 203 driven by the pushing away cylinder 202 and connected to the sliding guiding pair 6, the sliding guiding pair 6 Keep the pushing beam 203 in horizontal translational motion. The straight stick assembly 3 includes a wrist-turning frame 301 and a pair of rotatable vertical sticks 302 moun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com