Glue injection and compaction fixture

A tooling and glue injection technology, applied in the direction of workpiece clamping devices, manufacturing tools, hand-held tools, etc., can solve problems such as unqualified, uneven upper and lower flanges, expansion, etc., and achieve convenient operation, simple structure, and high glue injection quality Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

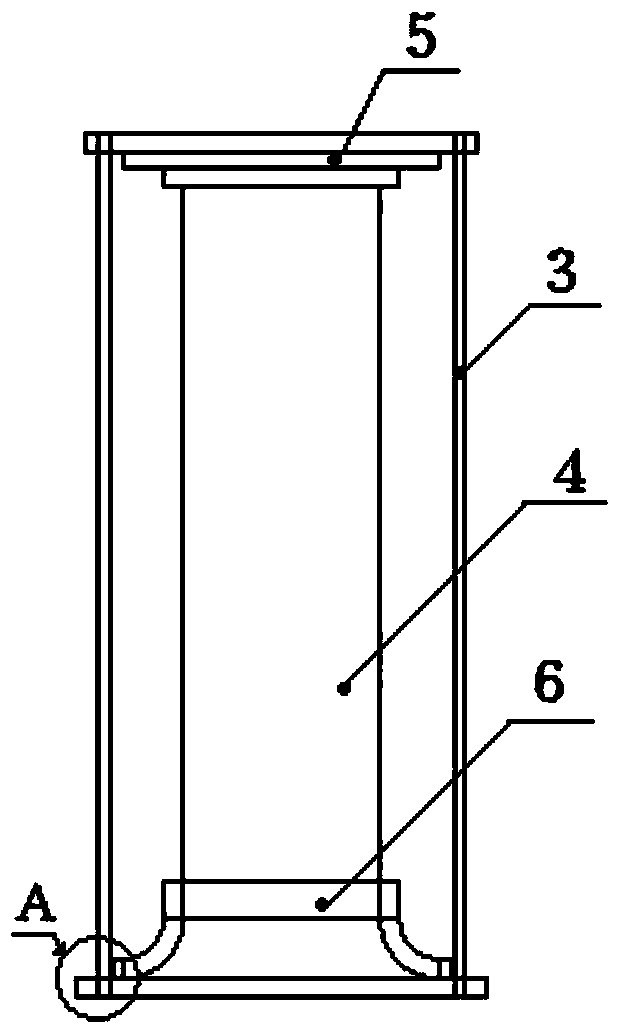

[0015] figure 1 Shown is the structural representation of the present invention.

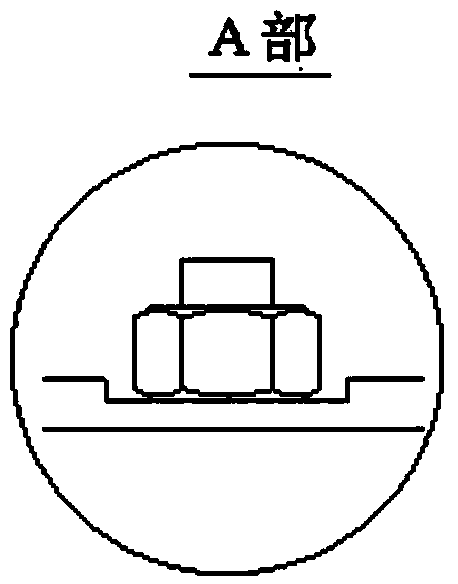

[0016] figure 2 shown as the present invention figure 1 The enlarged schematic diagram of part A.

[0017] The present invention includes an epoxy pipe 4, an upper flange 5 and a lower flange 7, an upper pressing plate 1, a lower pressing plate 2, a pull rod 3 and a base 6.

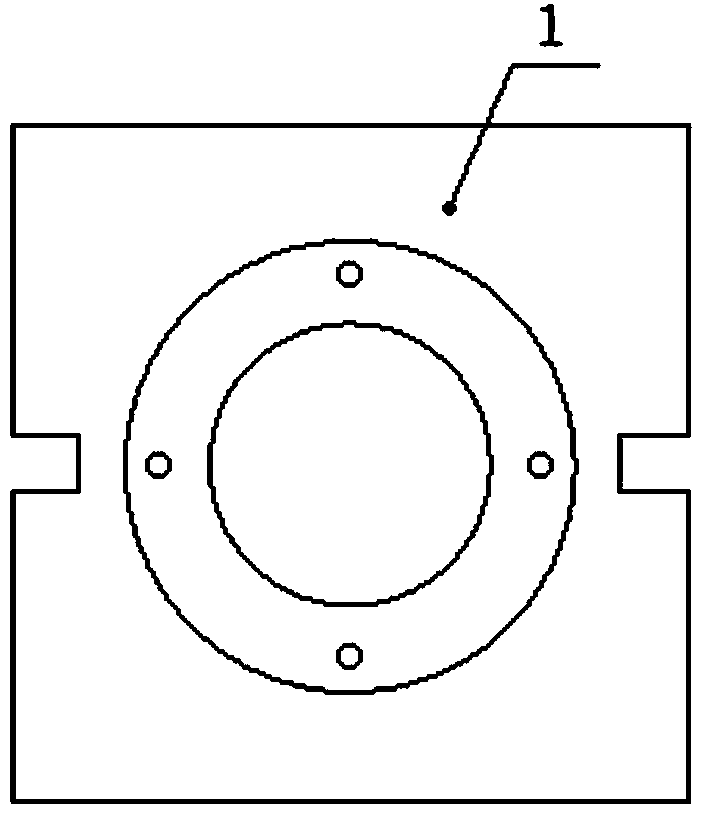

[0018] image 3 Shown is a schematic structural view of the upper platen of the present invention.

[0019] The upper platen 1 is a square structure with a screw hole in the middle and a groove on both sides. The upper flange 5 is fixed on the lower plane of the upper platen 1 by bolts.

[0020] Figure 4 Shown is a structural schematic diagram of the lower pressing plate of the present invention.

[0021] The lower platen 2 is a square structure, the middle part is provided with a base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com