Universal adjusting centering clamping device

A clamping device and universal technology, applied in the field of universal adjustment and centering clamping device, can solve the problems of high processing cost and use cost, low processing efficiency, easy to scratch tiles, etc., to reduce processing cost and use Cost and positioning process save time and effort, and the effect of low development cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

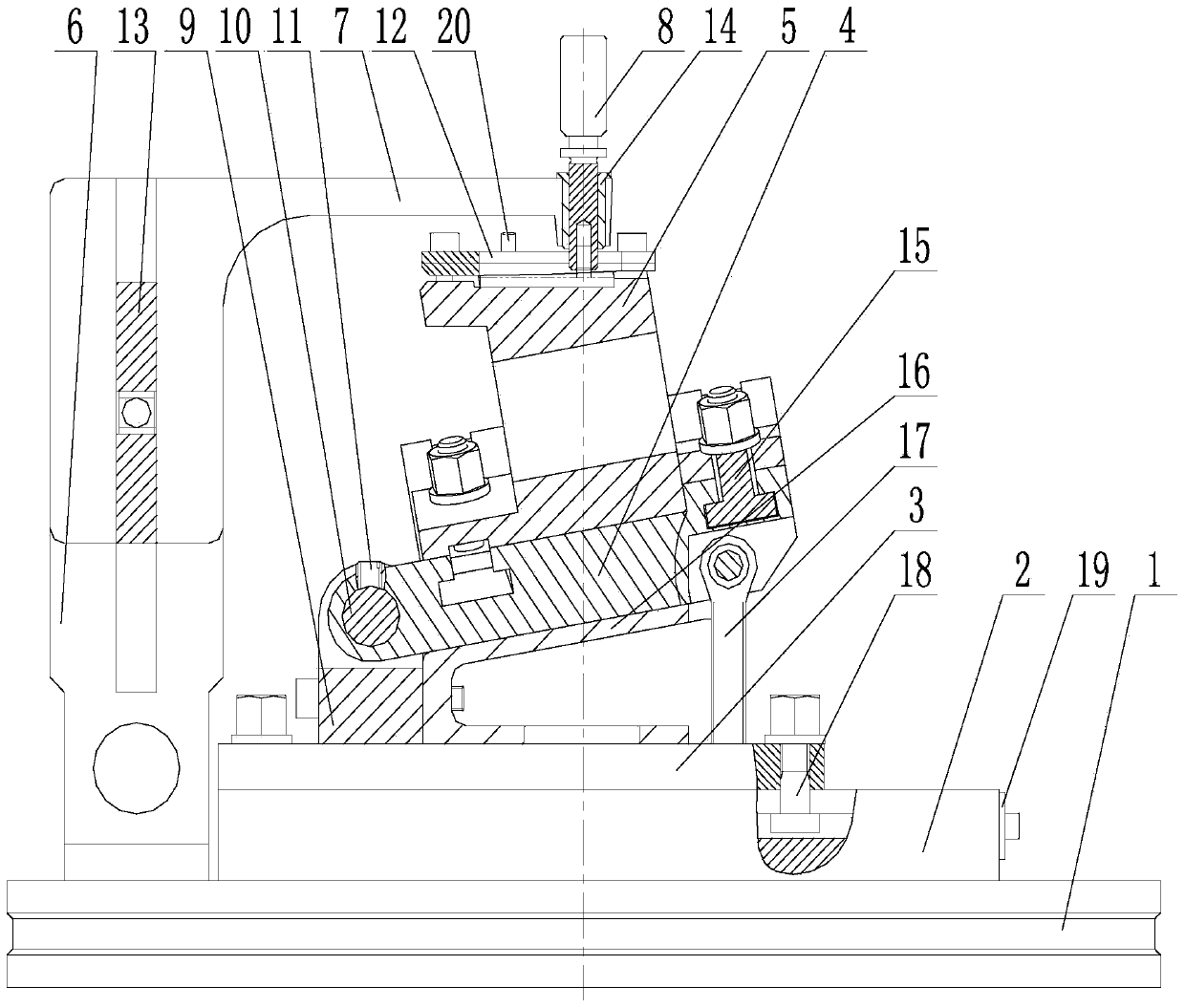

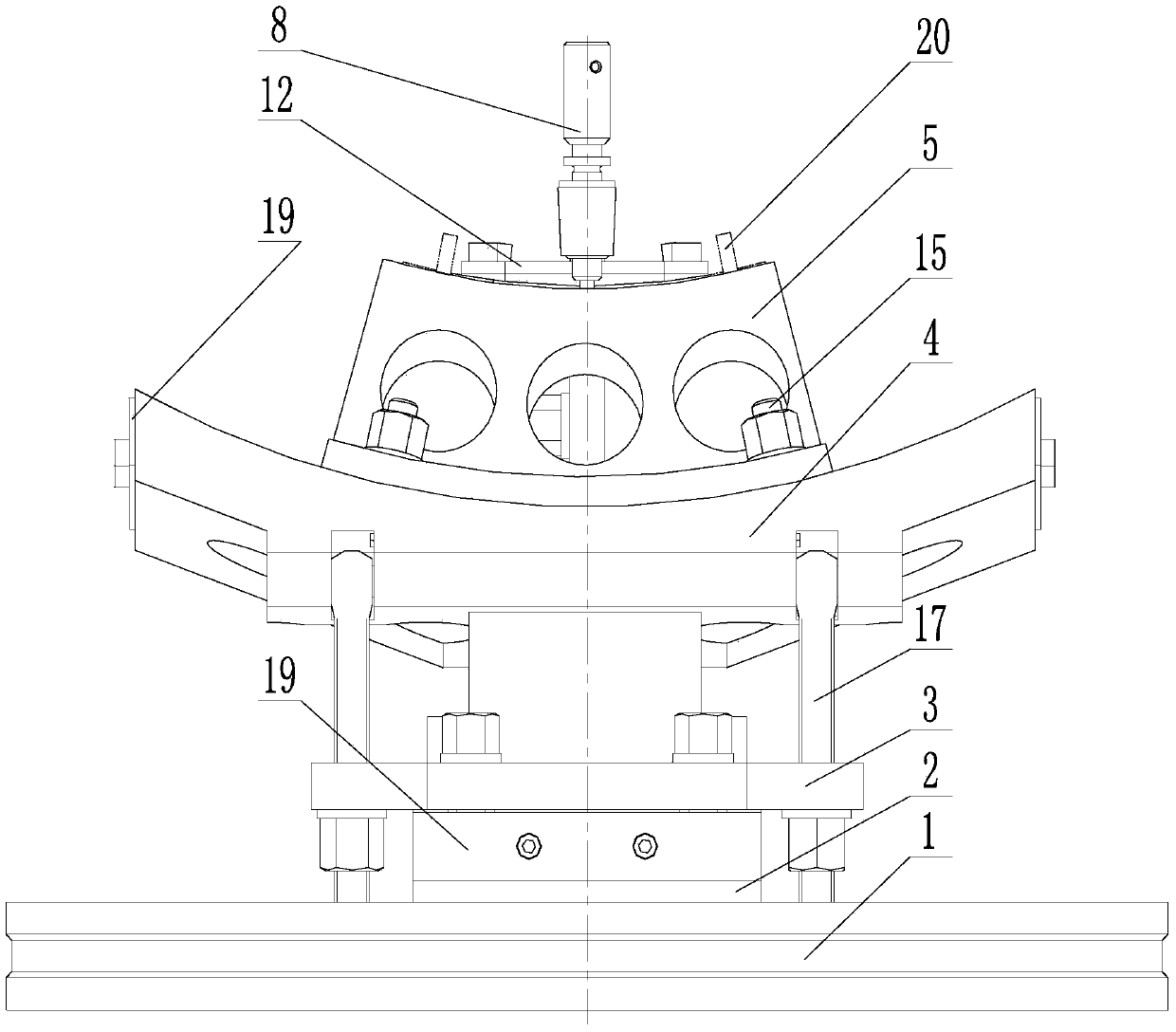

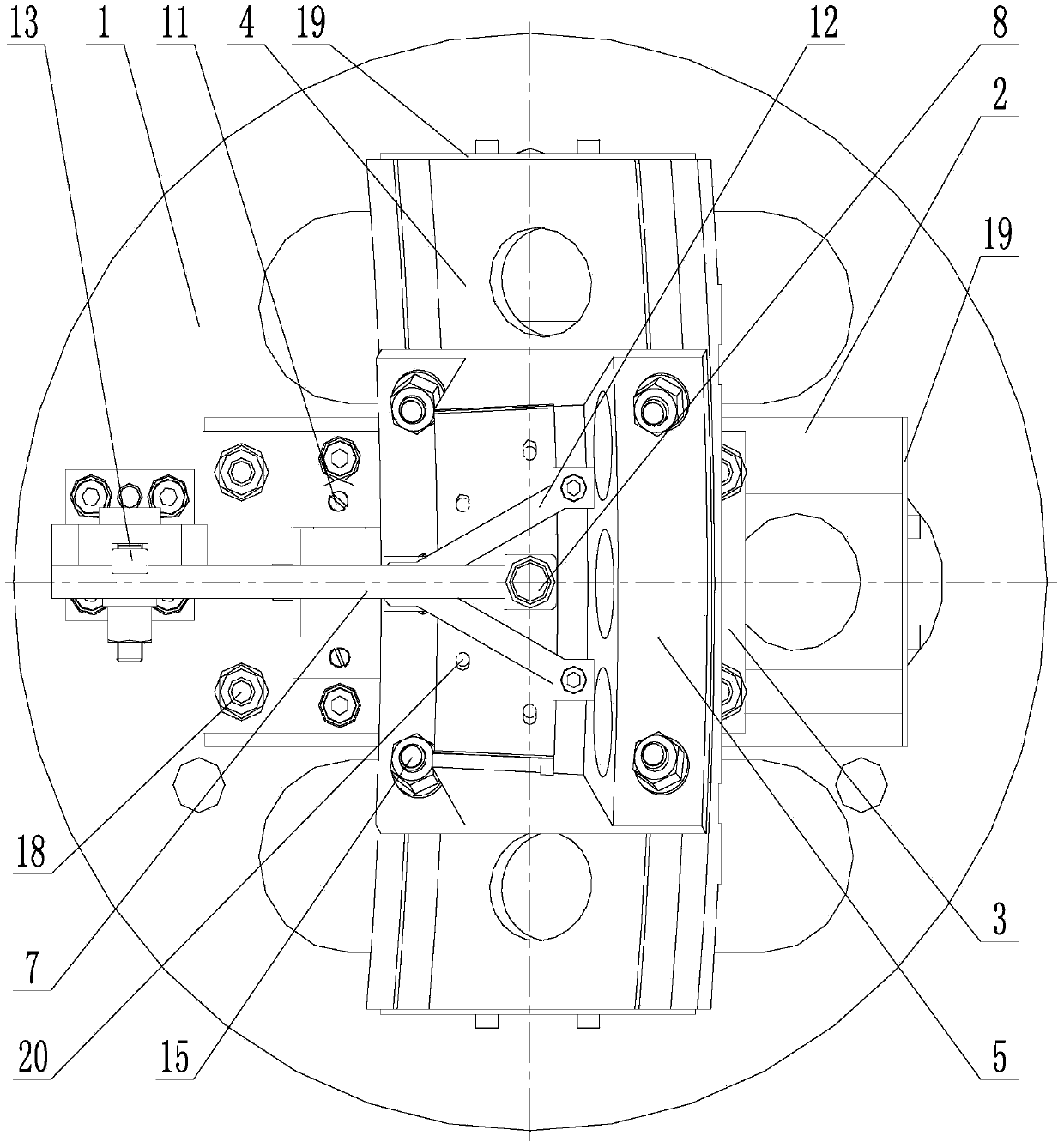

[0019] Such as figure 1 , 2 , 3, a universal adjustment centering clamping device, including a base 1, a plane track plate 2, a plane slide 3, an arc track plate 4, an arc slide 5, a bracket 6 and a center arm 7, The base 1 is configured as a disc-shaped structure, the plane track plate 2 is fixed on the base 1, and two mutually parallel T-shaped grooves are arranged on the upper end of the plane track plate 2; the plane slide seat 3 is arranged on a plane The upper part of the track plate 2 is slidably matched; four second T-bolts 18 are installed on the plane slide 3, and the plane slide 3 is connected with the plane track plate 2 through the second T-bolts 18, and every two The T-shaped head of the second T-shaped bolt 18 is located in the T-shaped groove of a plane track plate 2; 10 is connected with the rotating shaft fixed se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com