Method for machining large-radius thin-wall semi-annular part

A processing method and semi-circular ring technology, applied in metal processing equipment, manufacturing tools, accessories of toolholders, etc., can solve the problems of easy deformation, scrapping, difficult to ensure geometric accuracy, etc., so as to improve the pass rate and improve the geometric accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

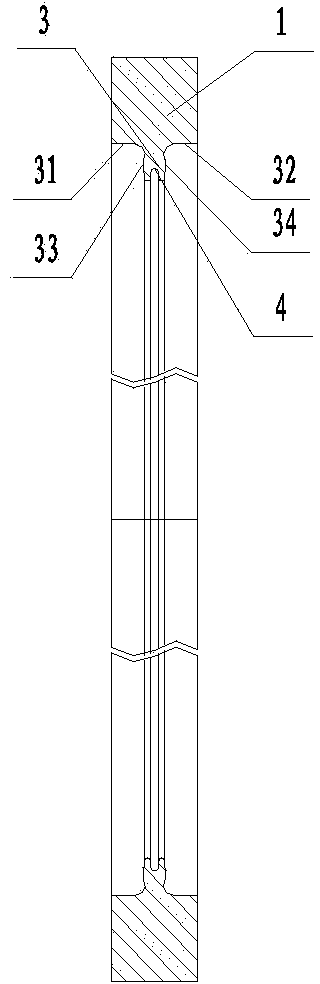

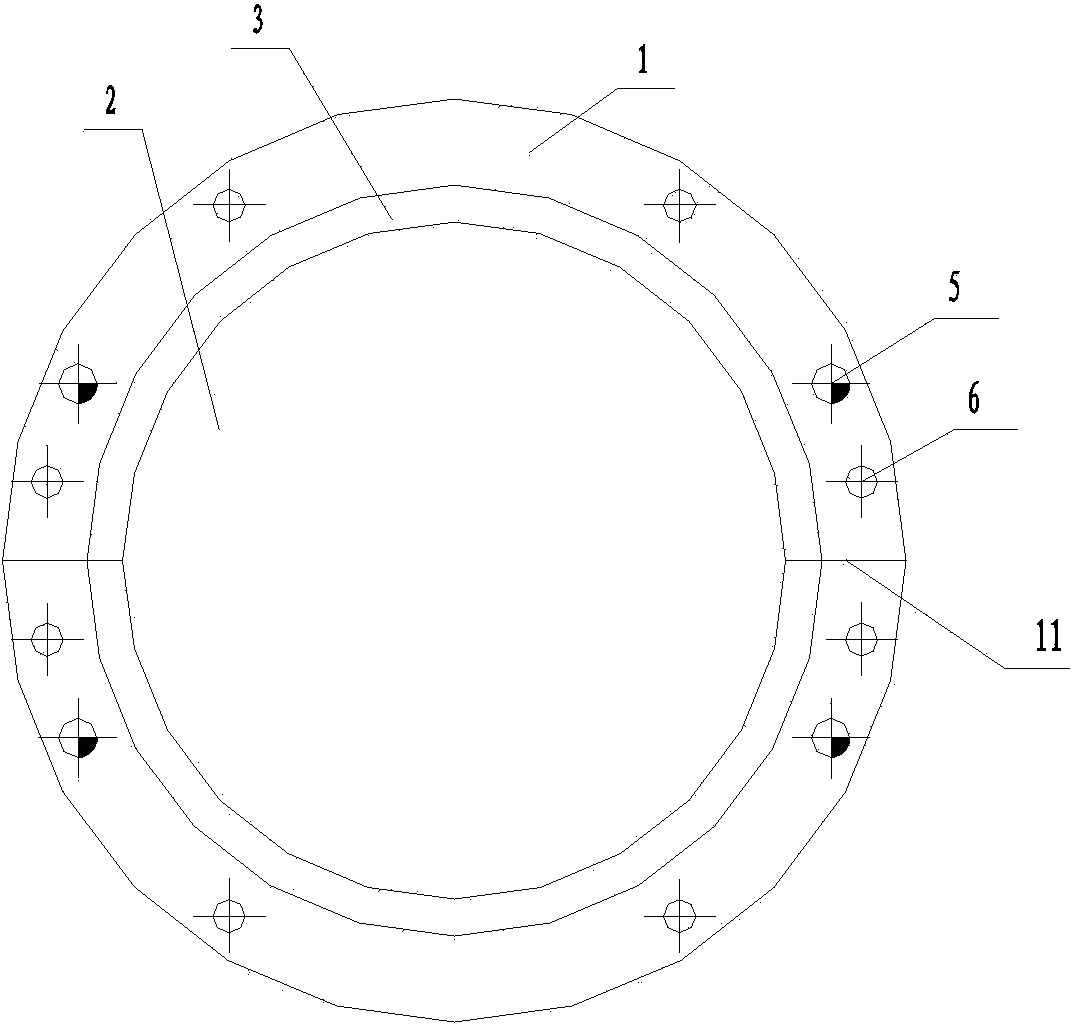

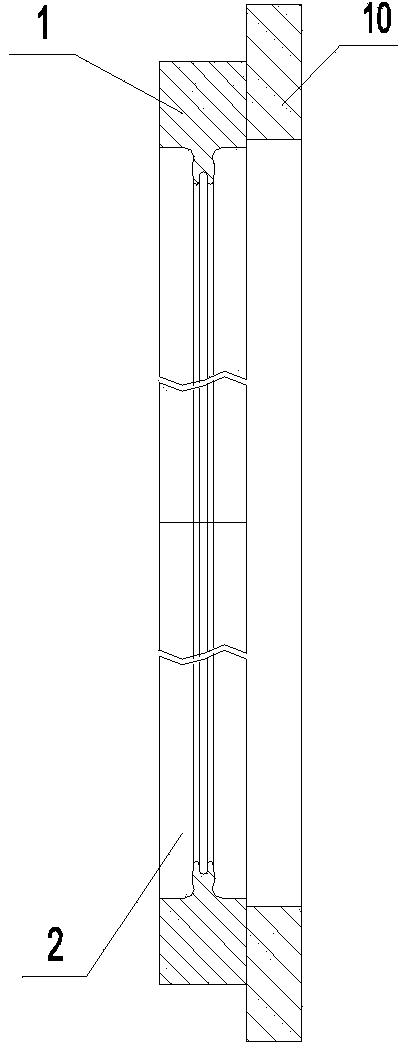

[0032] Such as Figure 1 to Figure 10 As shown, a method for processing large-radius thin-walled semi-circular parts specifically includes the following steps:

[0033] Step 1: Roughly machine the contour of the entire ring;

[0034] Use forgings to prepare materials according to a full-circle part, leave a margin of 5mm for the maximum outer contour, and rough-machine the inner hole 2, outer circle, and left and right two ends on the full-circle part to form a full-ring part, leaving 3-4mm on each side Allowance; then the whole ring part is subjected to high temperature tempering heat treatment, and the inner hole 2, outer circle and left and right two ends are roughed again, leaving 2 to 2.5mm allowance on each side;

[0035] Preparation material: 4Cr5MoV1Si; lathe model used for lathe processing: PT39; high temperature tempering ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com