Automatic tray seedling picking and releasing device with movable finger and automatic tray seedling picking and releasing method

An automatic pick-and-place and plug-in seedling technology, which is applied in planting methods, applications, agriculture, etc., can solve the problems of difficult control and stability of gripping force, low success rate of seedling picking, and easy drop of seedlings in the tray, so as to avoid clipping Unstable force taking, simple and reliable operation, and the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The structure, principle and working process of the present invention will be further described below in conjunction with the accompanying drawings. It should be noted that the specific embodiments are only examples to illustrate the present invention, and are not intended to limit the disclosed scope of the present invention.

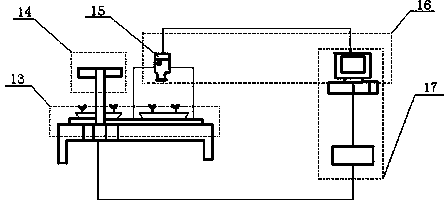

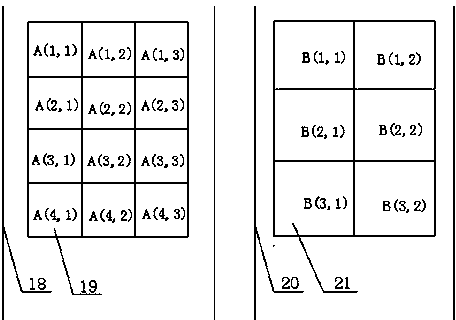

[0035] figure 1 and figure 2It is a schematic diagram of the automatic transplanting system for plug seedlings, including a plug transfer system 13; a transplanting mechanism system 14; a CCD camera 15; an image recognition processing system 16; a control system 17; The seedling transplanting tray 19 of A; the seedling tray conveyor belt 20; the seedling tray 21 comprising a plurality of seedling hole trays B.

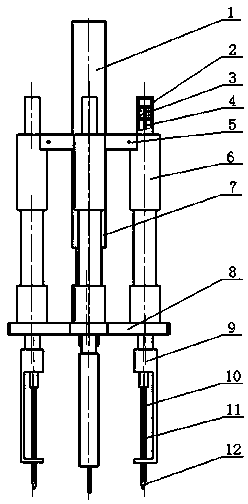

[0036] image 3 The automatic pick-and-place seedling device of the plug seedling of the present invention is shown. Including mechanical cantilever palm 1, support rod 7, finger distance adjustment plate 8, functional stopper with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com