Scale for rotary encoder, method of injection-molding same, and rotary encoder using same

A technology of rotary encoder and scale, which is applied in the direction of converting sensor output, instrument, measuring device, etc., can solve the problems of difficulty in improving the resolution of the rotary encoder, difficulty in maintaining the accuracy of the flash mold, difficulty in maintaining the performance of the rotary encoder, etc., to achieve maintaining Accuracy, suppression of variation in performance between products, and effect of widening the irradiation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] One embodiment of the present invention will be described with reference to the drawings.

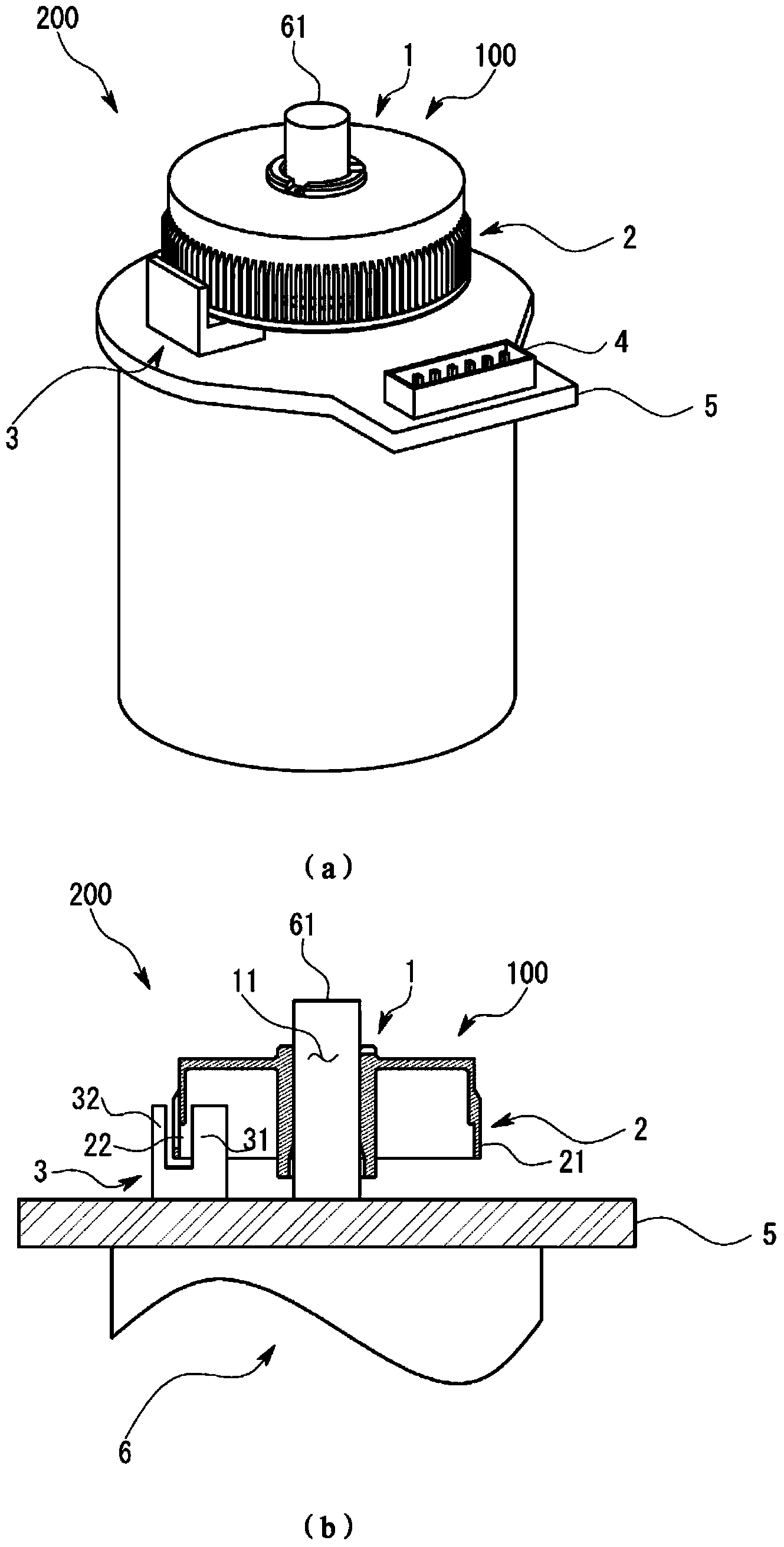

[0055] The rotary encoder scale 100 and the rotary encoder 200 of this embodiment are used, for example, to detect the rotation angle of small motors 6 such as printers and home appliances, and are particularly suitable for devices that house various devices and have a limited volume.

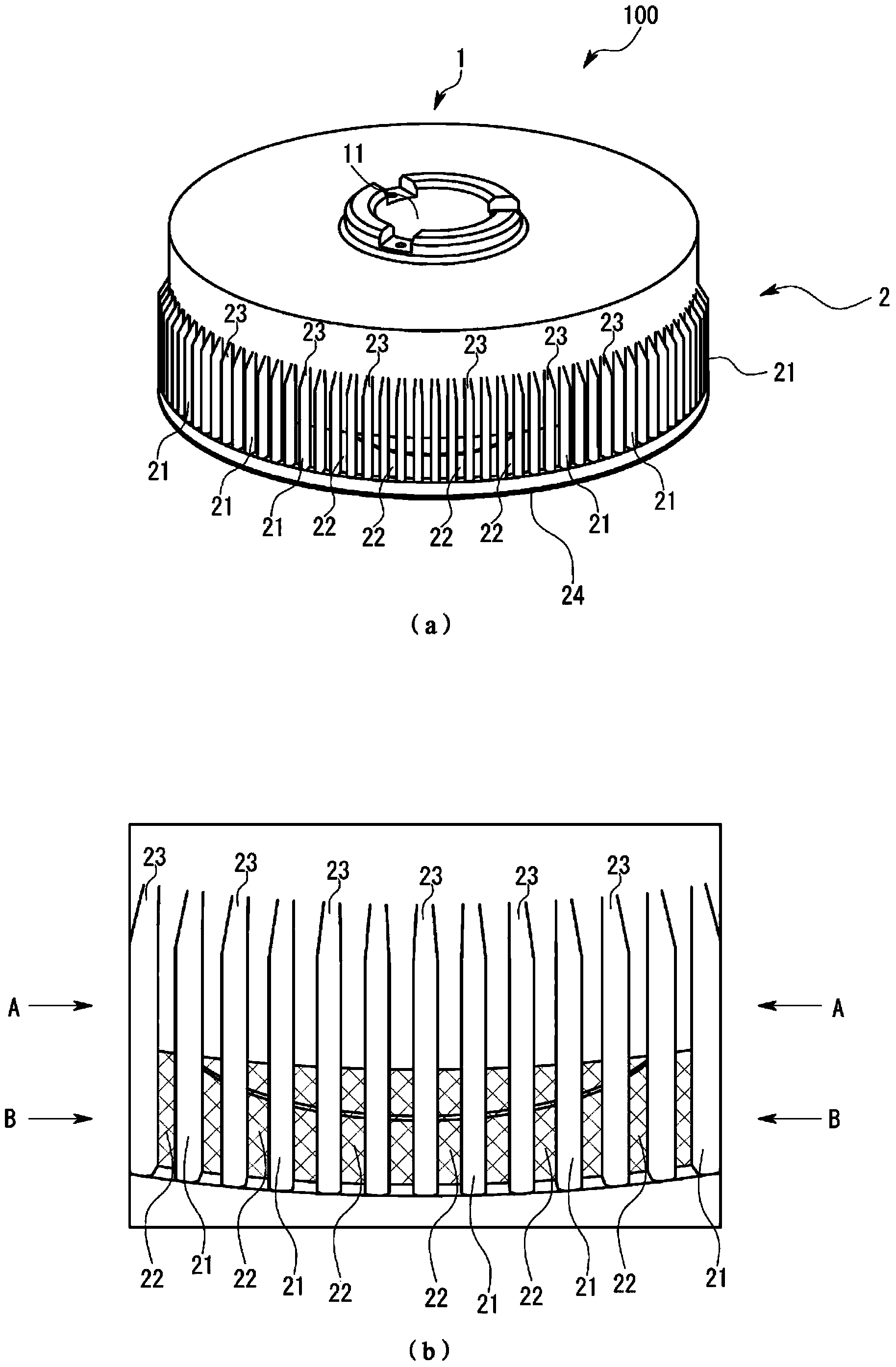

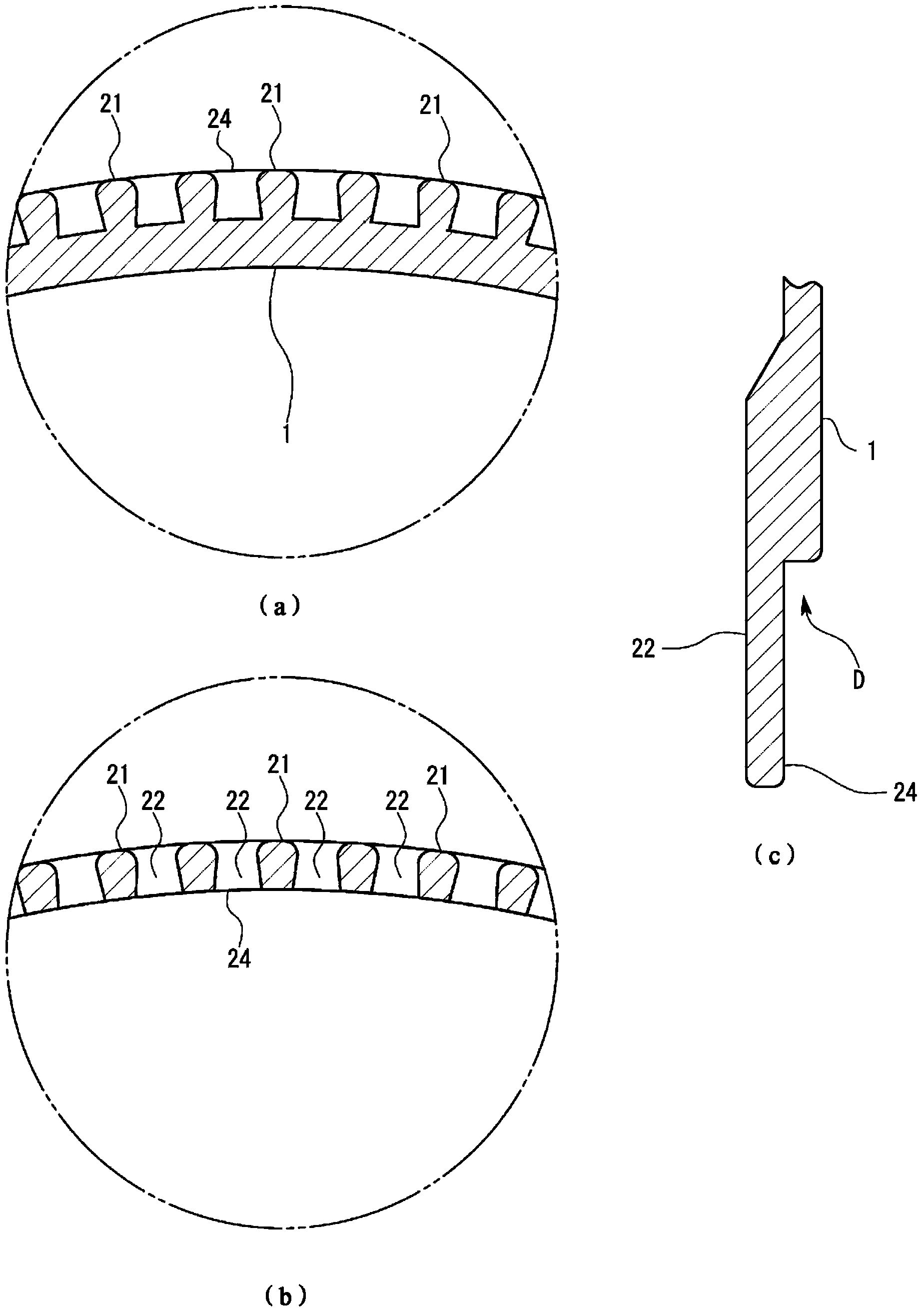

[0056] figure 1 The perspective view of (a) shows the state in which the rotary encoder 200 is attached to the small motor 6 . The rotary encoder scale 100 is generally flat cylindrical with an open bottom, the upper surface is fitted to the output shaft of the motor 6 , and the bottom is attached so as to face the main body of the motor 6 . In addition, the entire scale 100 for a rotary encoder is formed of resin. And, if figure 1 As shown in the perspective view of (a), a wiring substrate 5 for wiring is installed between the scale 100 and the main body of the motor 6, and the wiring substrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com