LED bulb

A technology for LED bulbs and LED light sources, which is applied in lampshades, lighting and heating equipment, semiconductor devices of light-emitting elements, etc., can solve the problems of low heat dissipation efficiency, low system efficiency, and large light loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

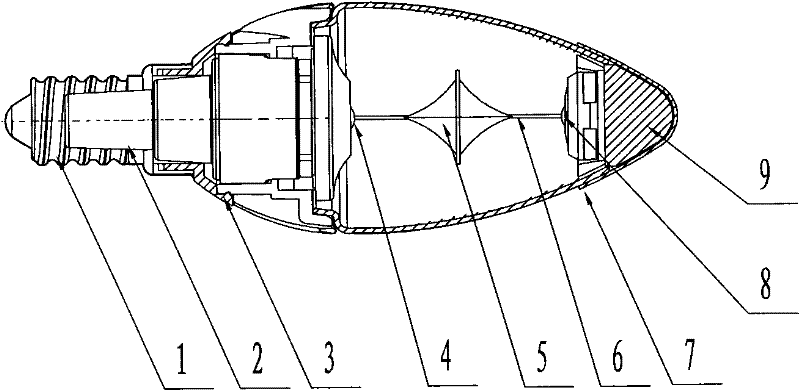

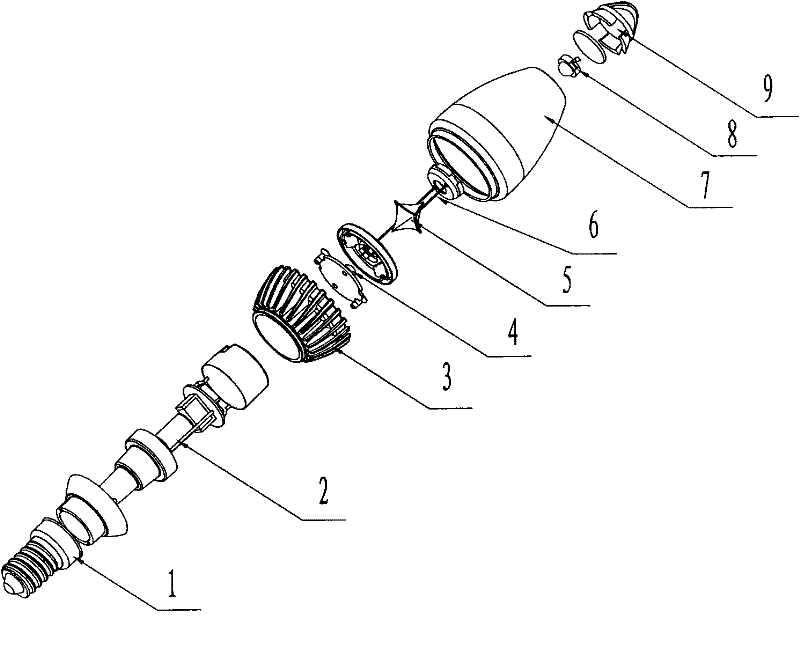

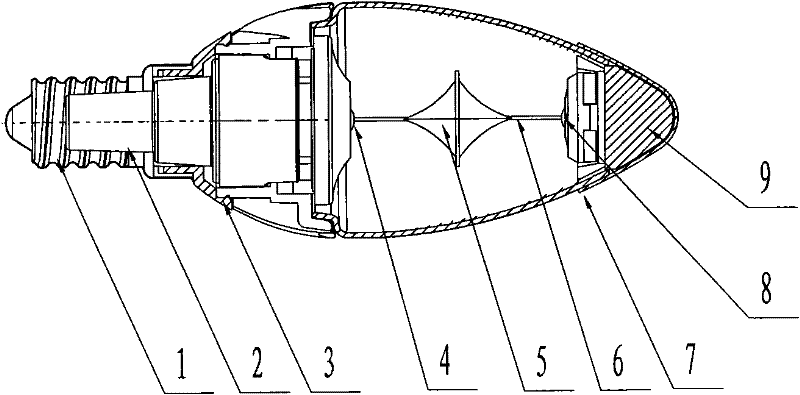

[0012] Such as figure 1 , figure 2 As shown, this embodiment uses 2 LED light sources, and 4, 6, and 8 LED light sources can also be used. The LED light bulb is composed of a lamp holder 1, a driver 2, a lower cooling block 3, a lower LED light source 4, a polyhedral light distribution optical device 5, a conductive support body 6, a transparent cover 7, an upper LED light source 8, and an upper cooling block 9. . The lower LED light source 4 is fixed on the lower cooling block 3, and the upper LED light source 8 is fixed at an appropriate position on the upper cooling block 9, which can quickly dissipate the heat generated by the upper and lower LED light sources, and at the same time support the middle polyhedral light distribution optical device 5. The conductive support body 6 is electrically connected to the lower LED light source 4 and the upper LED light source 8, so that the lower LED light source 4 and the upper LED light source 8 can be energized, and the multi-f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com