Zinc-nickel battery negative electrode sheet and preparation method thereof, and zinc-nickel battery using the same

A zinc-nickel battery and battery negative electrode technology, applied to battery electrodes, alkaline battery electrodes, circuits, etc., can solve the problems of battery short circuit, unfavorable winding core into the shell, and plate burrs, etc., to increase the effective negative electrode/positive electrode Capacity ratio, beneficial to increase and maintain, and reduce the effect of battery internal pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Preparation of the positive electrode: 90g of spherical nickel hydroxide, 5g of cobaltous oxide and 5g of T255 nickel powder are mixed evenly with an appropriate amount of CMC with a mass concentration of 2.5% and a PTFE aqueous solution with a mass concentration of 60% to make a positive electrode slurry, and then draw The slurry is put into the foamed nickel pre-pressed to a certain thickness, dried, rolled, and cut into a nickel positive electrode with a length and width of 90mm×43mm.

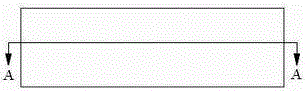

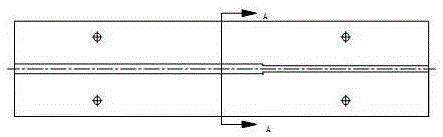

[0015] Preparation of the negative electrode: mix 86g of zinc oxide, 6g of bismuth oxide, 8g of calcium hydroxide with an appropriate amount of 2.5% CMC aqueous solution, 4% polyvinyl alcohol solution and 60% PTFE aqueous solution. The negative electrode slurry is made, coated on both sides of the tin-plated punched copper strip through a slurry drawing die, dried, rolled, and cut into a zinc negative electrode with a length and width of 122mm×43mm and a gradient thickness. The specifi...

Embodiment 2

[0021] The positive electrode preparation of the control group is the same as the above-mentioned specific embodiment, and the production material and formula of the negative electrode sheet are the same as the above-mentioned specific embodiment. Sheets, the manufacturing method of the battery is also basically the same as the above-mentioned specific embodiment, and there is no need to distinguish the front and rear ends of the winding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com