Method for simultaneously measuring multiple parameters of linear visco-elastic thin layer material by employing ultrasonic flat probe

A thin-layer material, ultrasonic technology, applied in the direction of using sound wave/ultrasonic wave/infrasonic wave to analyze solids, etc., can solve the problems of measurement result influence, wrong fitting result, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

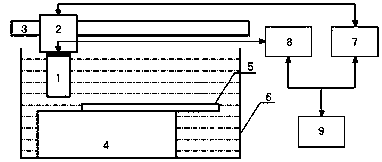

[0065] 2) Adjust the position of the linear motor 2 so that the ultrasonic flat probe 1 is located directly above the reference base material 4, and measure the ultrasonic echo signal s on the surface of the reference base material 4 0 (t);

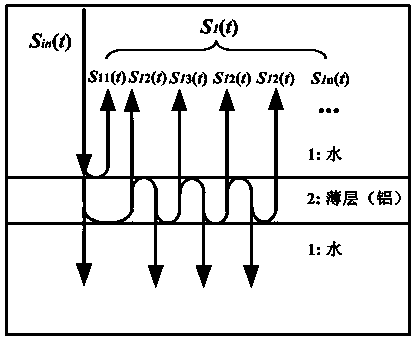

[0066] 3) Find the part of the thin-layer material 5 protruding from the surface of the reference base material 4, that is, the part where the upper and lower surfaces of the thin-layer material 5 are completely immersed in water, and control the movement of the linear motor 2 so that the ultrasonic flat probe 1 is located on the surface of the thin-layer material 5. Measure the ultrasonic echo signal s of the thin layer material 5 directly above the part of the surface of the reference base material 4 1 (t);

[0067] 4) Respectively for the ultrasonic echo signal s 0 (t), s 1 (t) performing low-pass filtering;

[0068] 5) for Z 2 Pick an estimate Z e2 , calculate s according to the formula 11 Estimated value of (t) s e11 (t):

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com