Test piece and method for testing fracture toughness of hybrid mode of double-material interface

A fracture toughness and hybrid mold technology, applied in the direction of applying a stable bending force to test the strength of materials, can solve the problems of difficulty in making brittle materials, unsuitable for fracture toughness, etc., and achieve the effect of simple geometry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0048] Material 1 and material 2 are two different ceramic materials combined by sintering. The Young's modulus of material 1 is 210GPa and Poisson's ratio is 0.31, and the Young's modulus of material 2 is 70GPa and Poisson's ratio is 0.27.

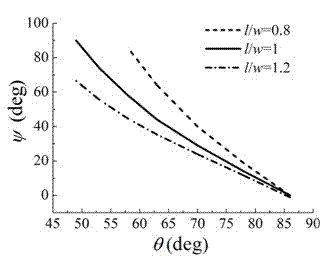

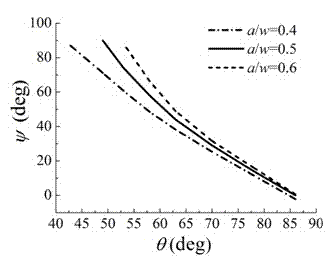

[0049] 1) Refer to the national standard and the nature of the specimen to select the span l =20mm, l 2 =2mm. Then, a trial calculation is carried out by displacement extrapolation method, l / w When taking different values, ψ with θ The value changes as figure 2 shown, seen, l / w The larger the value, the minimum required to achieve a 90° phase angle θ The smaller the value; a / w When taking different values, ψ with θ The value changes as image 3 as shown, a / w The larger the value, the minimum required to achieve a 90° phase angle θ The larger the value. because θ The specimen with larger value is easier to process, so it is selected by comparison l / w =1, a / w =0.5, that is w =20mm, a =10mm, and ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Poisson's ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com