Method for inspecting low-magnification microstructure defects of titanium alloy raw materials

A technology of low magnification structure and raw materials, which is applied in the field of inspection of low magnification structure defects of titanium alloy raw materials, can solve the problem that the macro structure of titanium alloy raw materials cannot be found, and achieve the effect of intuitive judgment.

Active Publication Date: 2016-06-08

中国第二重型机械集团德阳万航模锻有限责任公司 +1

View PDF3 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] In order to overcome the deficiency that the existing conventional low-magnification corrosion method inspection cannot find the abnormal macrostructure of titanium alloy raw materials, the technical problem to be solved by the present invention is to provide a method for detecting low-magnification structural defects of titanium alloy raw materials that can find abnormal macrostructures of titanium alloy raw materials. method

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and experiment the present invention is further described.

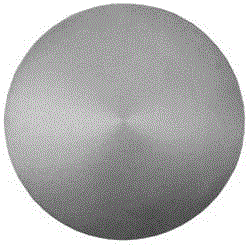

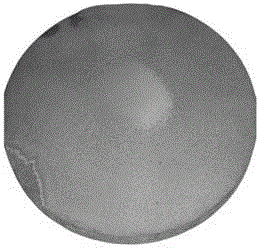

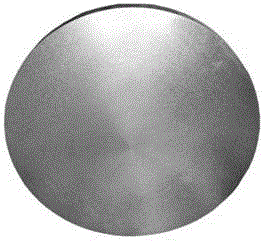

[0021] Such as Figure 1 to Figure 6 As shown, the method of the present invention is found and obtained through the following experiments.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a method for inspecting low-magnification structural defects of titanium alloy raw materials that can detect abnormal macrostructures of titanium alloy raw materials. The method can detect tissue genetic defects caused by abnormal forging deformation of titanium alloy raw materials after ingot casting. Cut a 20mm ± 3mm thick low-magnification tissue test piece from the titanium alloy raw material, first heat it in a heating furnace at 30-40°C below the β-transition temperature for 60 minutes, then raise the power to 15-20°C above the β-transition temperature, and the furnace temperature is uniform The stability requirement is within ±5°C, keep warm for 30 minutes and then air-cool, and then observe the low-magnification structure after corrosion. This method is suitable for the inspection of the low-magnification structure of α-type, α-β-type and near-β-type titanium alloy raw materials. The judgment of the macrostructure defects of titanium alloy raw materials is intuitive and clear, and it can control the production of forgings with titanium alloy raw materials with macrostructure defects. the resulting economic losses.

Description

technical field [0001] The invention relates to a method for inspecting metal macrostructure defects, in particular to a method for inspecting low-magnification structure defects of titanium alloy raw materials. Background technique [0002] Due to its high specific strength and excellent corrosion resistance, titanium alloys have been widely used in the fields of civil aviation and military aviation. Titanium alloy raw materials of various materials are used to forge frames, beam-bearing structural parts and core engine disks for aircraft. It has accounted for 20-40% of the total weight of the aircraft. In ensuring the safety of aircraft, the inspection and control of the macrostructure quality of titanium alloy raw materials is a key factor. [0003] At present, GB / T5168 is used to test the high and low magnification structure of two-phase titanium alloy raw materials in China. The defects that can be detected are pores, cracks, inclusions, delamination, and coarse grain ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01N1/28G01N1/44C22F1/18

Inventor 朱知寿曾菁沙爱学谢静王新南蒋佳君商国强

Owner 中国第二重型机械集团德阳万航模锻有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com