Machine vision device capable of achieving double-faced imaging

A machine vision, double-sided imaging technology, applied in the field of machine vision and equipment installation, can solve the problems of increasing the cost of the vision system, installing the camera and the movement conflict of the conveying device, and limited adjustment ability, achieving good environmental adaptability and ensuring environmental adaptability. The effect of stability and easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further explained below in conjunction with the accompanying drawings.

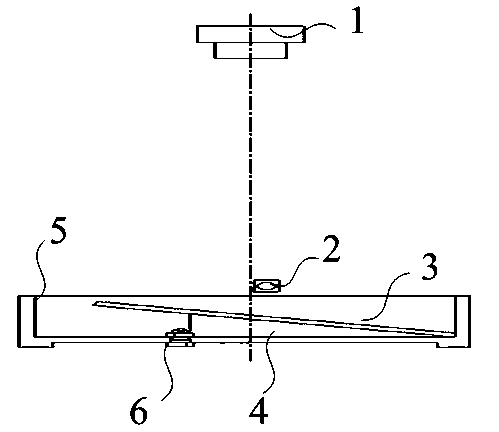

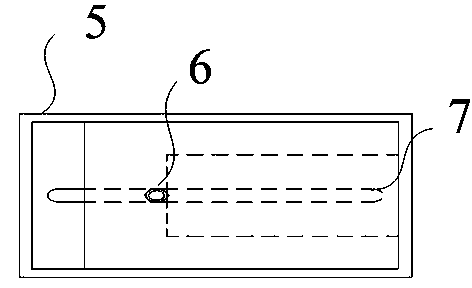

[0016] Such as figure 1 , figure 2 As shown, a double-sided imaging machine vision device of the present invention includes a camera 1, a mirror 3, a wedge 4, a mounting groove 5 and a fastening screw 6;

[0017] Described mounting groove is rectangular parallelepiped shape, and there is elongated through-hole 7 along the length direction in the middle of its bottom, is provided with wedge-shaped block 4 in the mounting groove, and the bottom of wedge-shaped block 4 is provided with fastening screw 6, and fastening screw Through the through hole 7, fixed by a fastening nut, a mirror 3 is arranged on the wedge block 4, and one side of the mirror is hinged with the mounting groove; the camera 1 is arranged directly above the mounting groove 5;

[0018] When working, the workpiece 2 is placed directly under the camera 1, and the wedge block 3 can push the rotation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com