Parallel ignition system for natural gas engine

An ignition system and engine technology, which is applied in the field of ignition systems to achieve the effects of simple structure, reliable ignition and optimized ignition energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

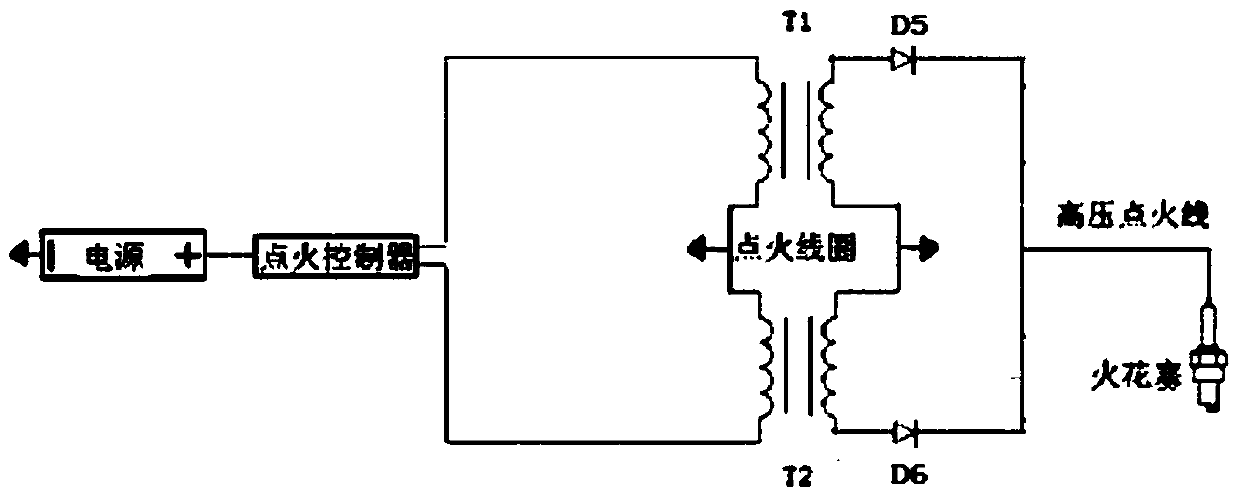

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

[0024] A parallel ignition system for a natural gas engine and a multi-mode discharge control method, mainly comprising: an ignition controller, a DC power supply, two ignition coils T1 and T2, two high-voltage diodes D5 and D6, a high-voltage ignition wire, a spark plug, and the like. Its characteristics are: one end of the primary ignition coil of the two ignition coils T1 and T2 is respectively connected to the ignition controller and then leads to the positive pole of the power supply, and the other end is connected to the negative pole of the power supply after being connected to the same ground; one end of the secondary ignition coil of the two ignition coils They are respectively connected to the anodes of two high-voltage diodes D5 and D6, and the other end is shared with the primary coil and the negative pole of the power supply. After the negative poles of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com