Network type seepage discharging device in transverse direction, longitudinal direction and vertical direction

A network-type, vertical technology, applied in the direction of water supply equipment, sewage discharge, waterway system, etc., can solve the problems of ineffective line effect, limited range of hydraulic influence, frequent fluctuation of infiltration line, etc., so as to reduce the infiltration line and air resistance The effect of small size and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

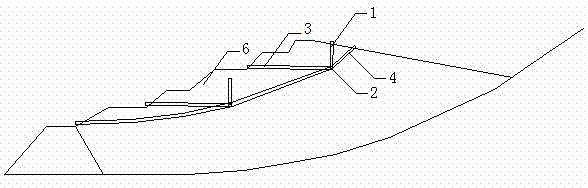

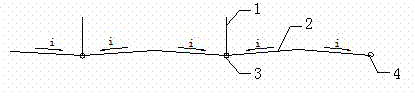

[0031] Referring to the accompanying drawings, this embodiment includes a vertical seepage collection body 1, a horizontal and horizontal seepage collection body 2, a horizontal and vertical drainage pipe 3, and a longitudinal flow guide pipe 4;

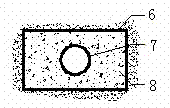

[0032] The horizontal lateral seepage collection body 2 is on the slope of the sedimentary shoal at the design elevation and the design distance from the outer edge of the accumulation dam crest (the accumulation dam crest refers to the last stage of the accumulation dam at a certain moment. The location of the crest, whose elevation is the highest elevation of the accumulation dam at a certain moment), when the surface of the sedimentary shoal of the accumulation dam body 6 can stand people, excavate a trench parallel to the axis of the accumulation dam body, and the cross-sectional shape of the trench is rectangula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com