Prestress sectional steel reinforcing system of reinforced concrete arch shell bridge body

A reinforced concrete and arch-shell bridge technology, which is applied in bridge reinforcement, bridge, bridge construction, etc., can solve the problems of unloading, high cost, and large amount of engineering, and achieves a clear force, simple structure, and convenient construction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with drawings and embodiments.

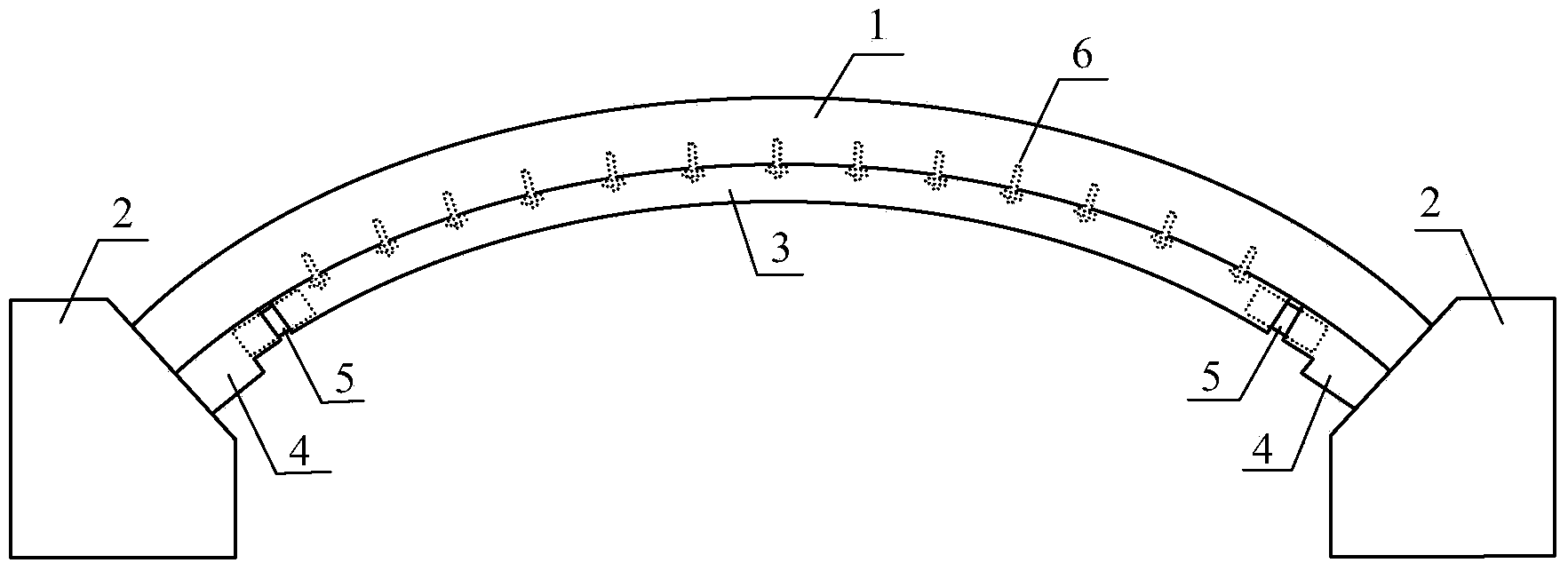

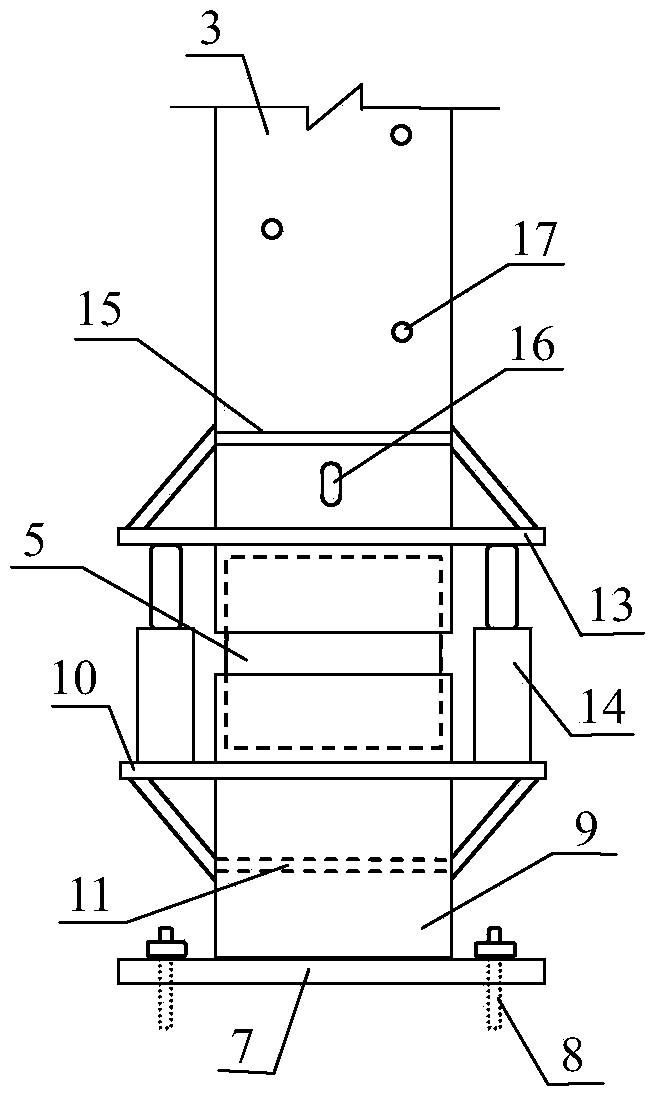

[0029] like Figure 1 ~ Figure 3 As shown, this embodiment includes longitudinal arched steel (channel steel) 3, steel support 4, and connecting steel sleeve 5. The steel support 4 includes a support base plate 7, a support steel body 9, a laterally extending corbel 10, and a top-extending section steel (channel steel) 12, and the support base plate is anchored with the concrete foundation 2 of the arch bridge with a bolt 8. The longitudinal shape of the longitudinal arch steel 3 is consistent with the longitudinal shape of the bottom of the reinforced arch shell 1. After it is in place, its top plate is in close contact with the reinforced arch shell, and the chemical bolt 6 is vertically connected to the arch shell at the elongated socket 16. Temporarily anchored laterally and laterally, but not fully anchored, allowing longitudinal movement. Corbels 13 protruding t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com