Liquid plating device for inner hole of slender pipe fitting

A slender tube and plating solution technology, which is applied in the field of slender pipe inner hole plating solution device, can solve the problems of poor fluidity of the inner cavity solution and low chrome plating efficiency, reduce the workload and production cost of the plating solution, and improve the efficiency of the plating solution. Efficiency, the effect of speeding up circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

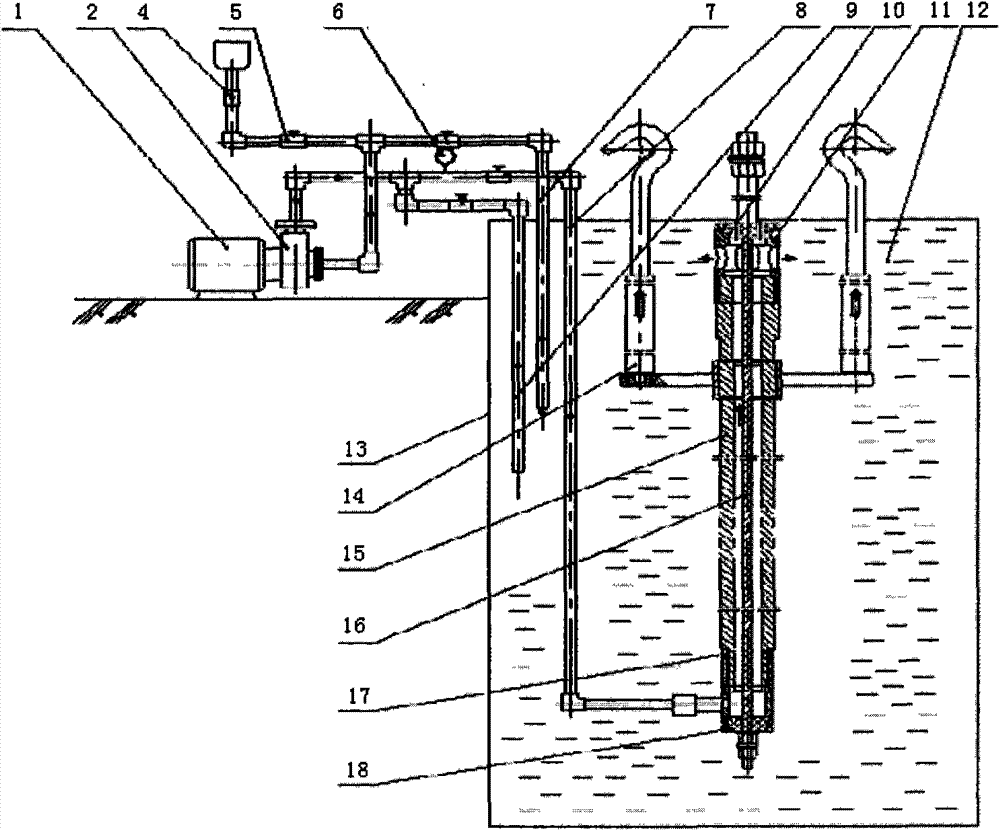

[0024] A kind of slender pipe inner hole plating solution device of the present invention, such as figure 1 As shown, it includes motor 1, pump body 2, liquid injection pipeline 4, liquid return pipeline 7, plating tank liquid inlet pipeline 8, liquid separation pipeline 9, cathode hanger 14, anode rod 16, upper cap 11, Upper insulating plate 10, lower cap 17, lower insulating plate 18.

[0025] The cathode hanger 14 includes a support plate, a hook, and a snap ring; a through hole is provided in the center of the support plate, hooks are fixed upward on both sides of the support plate, and a snap ring with an inner diameter matching the outer diameter of the elongated pipe fitting 15 is fixed in the center of the support plate;

[0026] The upper cap 11 has a cylindrical structure, the middle side wall of the upper cap 11 has a plating tank drain hole, the inner wall of the lower end of the upper cap 11 is processed with internal threads, and the inner wall of the upper end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com