Preparation method of polycondensed asphalt, preparation method of needle coke and needle coke

A technology of needle coke and pitch, which is applied in the field of needle coke, can solve the problem of single source of needle coke raw materials, and achieve the effects of improving overall economic benefits, high carbon content, and easy polymerization or crosslinking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

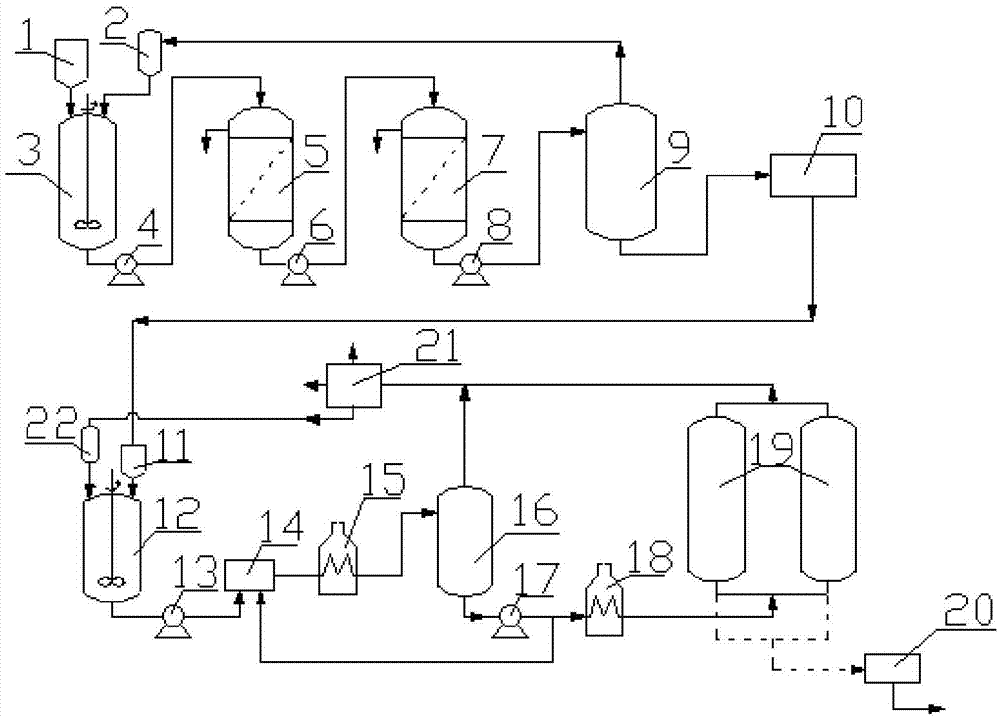

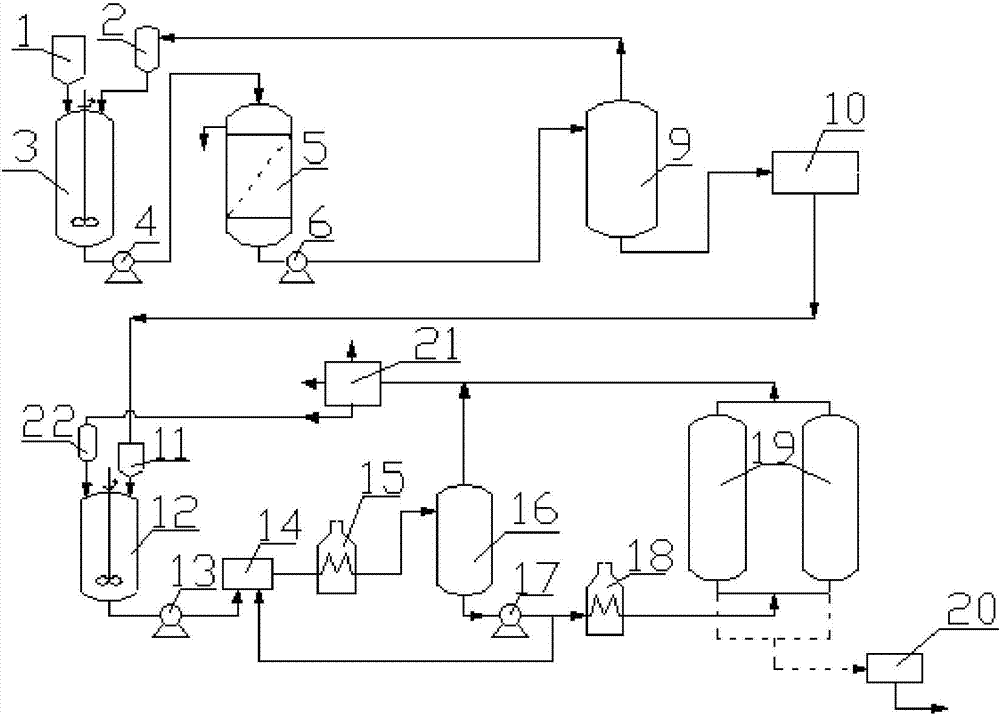

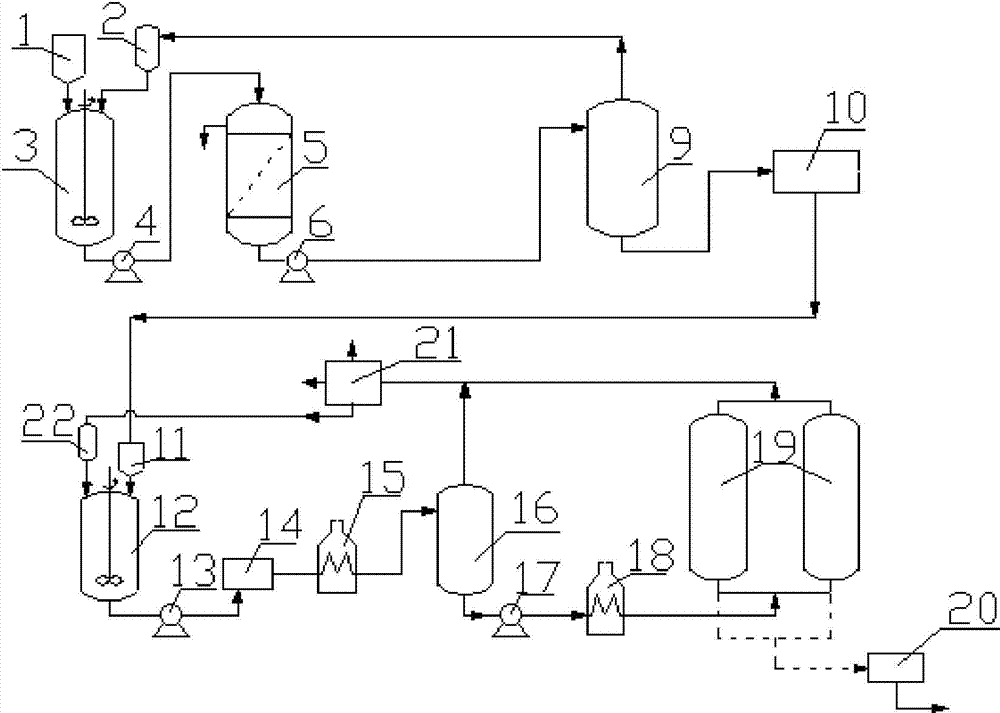

[0031] In order to solve the problem of single source of raw materials and high CTE for the preparation of needle coke mentioned in the background art, in a typical implementation of the present invention, a preparation method of polycondensation pitch is provided. The preparation method uses coal The liquefaction residue is used as the raw material. By adjusting the extraction solvent, the quinoline insolubles are separated, and the polycyclic condensed aromatics are retained to obtain the pitch raw material suitable for the synthesis of needle coke. The preparation method includes: step S1, using an extraction solvent to extract the pitch in the coal liquefaction residue to obtain refined pitch, the extraction solvent being selected from coal liquefied oil, N-methylpyrrolidone, tetrahydrofuran, quinoline, One or more of the group consisting of pyridine and anthracene oil; Step S2, making the powdery asphalt undergo polycondensation reaction to form polycondensed asphalt.

[...

Embodiment 1

[0056] Put ≤5mm coal liquefaction residue and pyridine into the stirring tank 3 according to the mass ratio of 1:1. After stirring evenly, extract under nitrogen pressure of 0.1MPa, temperature of 150°C, and stirring speed of 200r / min for 1 hour, and then extract The conveying pump is sent into the first-stage filter kettle, and under the protection of nitrogen, the mixed liquid is thermally filtered at a filtration temperature of 150°C and a pressure of 0.5MPa. The filtration accuracy of the filter material in the first-stage filter kettle is 50 microns; The extraction mixture is sent to the secondary filter tank by the primary filtrate delivery pump. Under the protection of nitrogen, the filtration temperature is 200 ° C and the pressure is 1 MPa. The mixed liquid is thermally filtered, and the filtration accuracy of the filter material in the secondary filter tank is 1 micron. ; Send the extraction mixed liquid into the vacuum distillation kettle by the secondary filtrate de...

Embodiment 2

[0059] Put ≤5mm coal liquefaction residue and anthracene oil into the stirring tank according to the mass ratio of 1:3. After stirring evenly, extract under nitrogen pressure of 1MPa, temperature of 200°C and stirring speed of 100r / min for 0.5 hours, and then transport through extraction Pump it into the first-stage filter kettle, and under the protection of nitrogen, heat-filter the mixed solution at a filtration temperature of 200°C and a pressure of 1MPa. The filtration accuracy of the filter material in the first-stage filter kettle is 30 microns; The liquid is sent to the secondary filter kettle by the primary filtrate delivery pump. Under the protection of nitrogen, the filtration temperature is 200°C and the pressure is 2MPa to thermally filter the mixed solution. The filtration accuracy of the filter material in the secondary filter kettle is 5 microns; The extraction mixture is sent to the vacuum distillation kettle by the secondary filtrate delivery pump, and the wash...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com