A reversible temperature-indicating powder coating and its preparation method and application method

A technology of powder coating and temperature indication, applied in the field of coatings, can solve problems such as solvent environmental pollution, and achieve the effects of prolonging the life of discoloration, high color retention, good decoration and weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

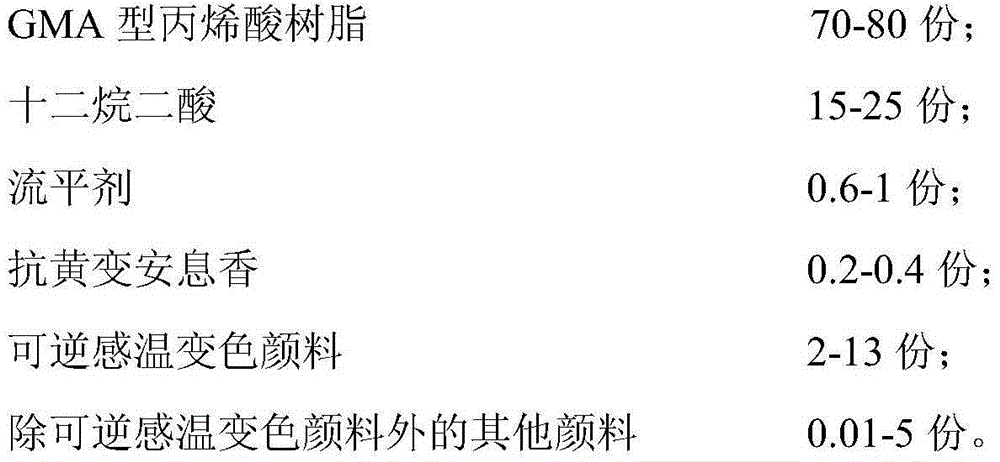

[0030] A reversible temperature-indicating powder coating, its raw material constituents and their weight parts are as follows:

[0031]

[0032] The preparation method of the above reversible temperature-indicating powder coating has the following steps:

[0033] The above materials are added to the high-speed mixer, and then added to the extruder after dry mixing. The temperature in the first zone is 80-90℃, and the extrusion temperature in the second zone is 110-120℃ for melting, mixing, extruding, cooling, Tablets are crushed, classified, sieved, and packaged by a pulverizer to become a powder coating product with a suitable particle size (usually 32-36um), that is, a reversible temperature-indicating powder coating.

[0034] The use method of the above-mentioned reversible temperature-indicating powder coating is as follows:

[0035] Spray the reversible temperature-indicating powder coating on the metal surface, or spray on the primer, and bake at 180°C for 15 minutes, especiall...

Embodiment 2

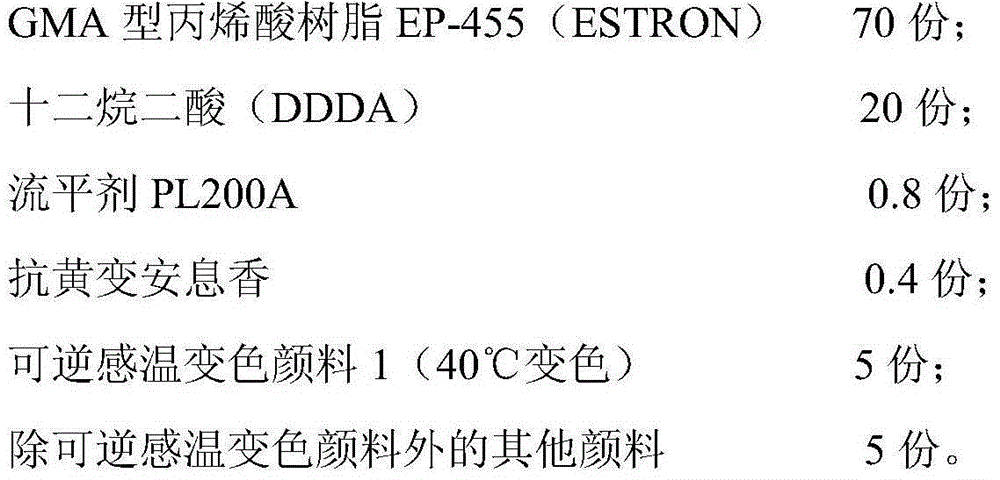

[0037] A reversible temperature-indicating powder coating, its raw material constituents and their weight parts are as follows:

[0038]

[0039] The preparation method and application method of the above-mentioned reversible temperature-indicating powder coating are the same as in Example 1.

Embodiment 3

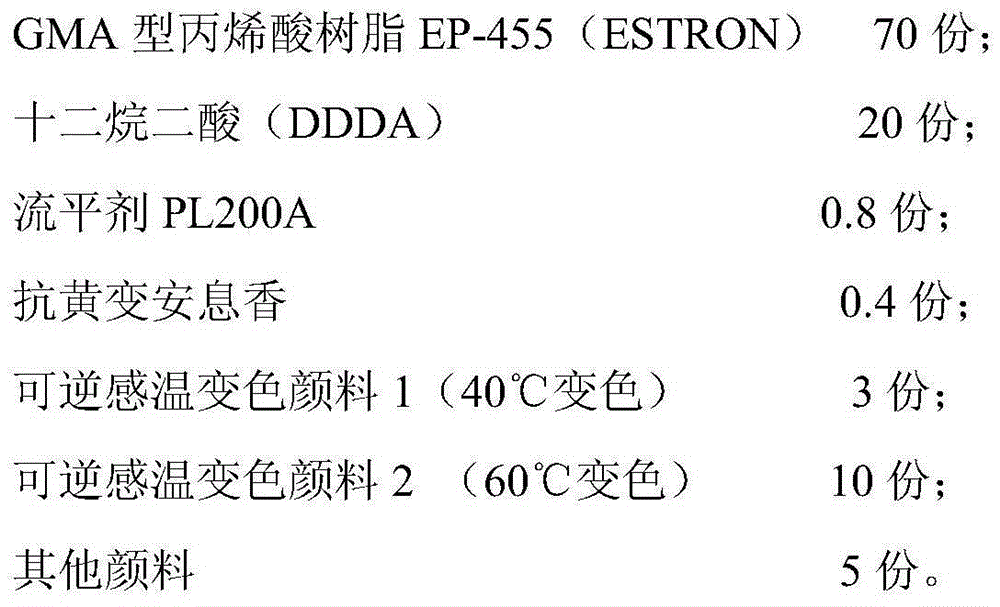

[0041] A reversible temperature-indicating powder coating, its raw material constituents and their weight parts are as follows:

[0042]

[0043] Actual application effect and test situation of the powder coating of the present invention:

[0044] In order to test the practical application effect of the present invention, the specific operation is as follows: spray the powder coating prepared in Example 1 on the phosphated metal surface, put it in a high-temperature oven and bake it at 180°C / 15-20 minutes After the solidification is complete, take out the sample and cool it to obtain sample A. Use the powder coatings prepared in Examples 2 and 3 to make samples. The production method is the same as that in Example 1, and sample B and sample C are obtained. Mainly compare the reversible temperature of A, B and C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com