Antistatic organosilicon gel used for heat-conducting gasket and preparation method of the organosilicon gel

A heat-conducting gasket and silicone technology, applied in the field of silicone electronic materials, can solve the problems of affecting the combination of colloid and substrate, poor antistatic effect, insufficient adhesion, etc., achieving good antistatic effect, fast heating and curing, Good adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

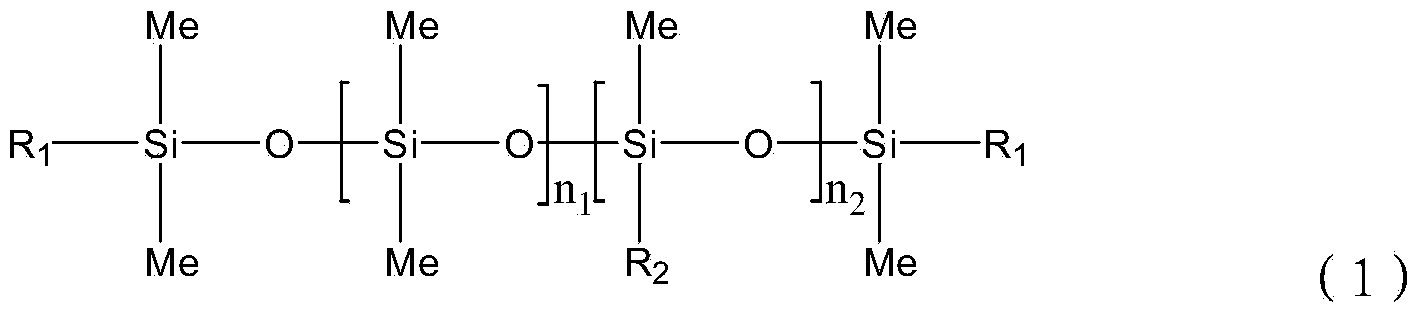

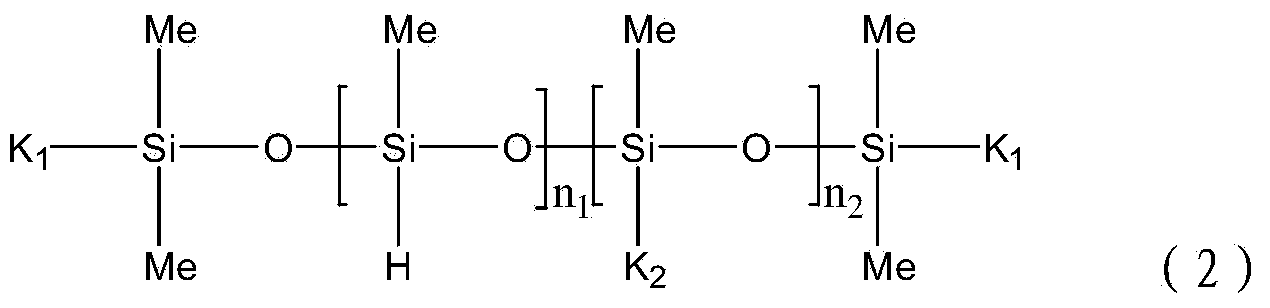

[0064] Preparation of component A: Weigh the viscosity of 10000 centipoise such as structural formula (1), where R 1 for-Vi, R 2 46.95 g of double-terminated vinyl polysiloxane (vinyl content: 0.1 wt%) of -Me, with a viscosity of 100 centipoise, such as structural formula (1), where R 1 , R 2 15.0g of -Vi terminal and side vinyl polysiloxane (vinyl content 10wt%), vinyl MQ resin such as molecular formula 1 (viscosity of 500 centipoise, vinyl content 5wt%) 35g, add adhesive such as Structural formula (3), n=5, 0.05g, add antistatic agent, such as structural formula (7), n=10, 2.0g, catalyst platinum (0)-2,4,6,8-tetramethyl-2, 1.0 g of 4,6,8-tetravinylcyclotetrasiloxane complex solution, with a platinum content of 1000 ppm, was sequentially added into the mixer, mixed and stirred evenly, and the A component was obtained;

[0065] Preparation of component B: Weigh the viscosity of 500 centipoise such as structural formula (1), where R 1 for-Vi, R 2 79.9g of double-terminated...

Embodiment 2

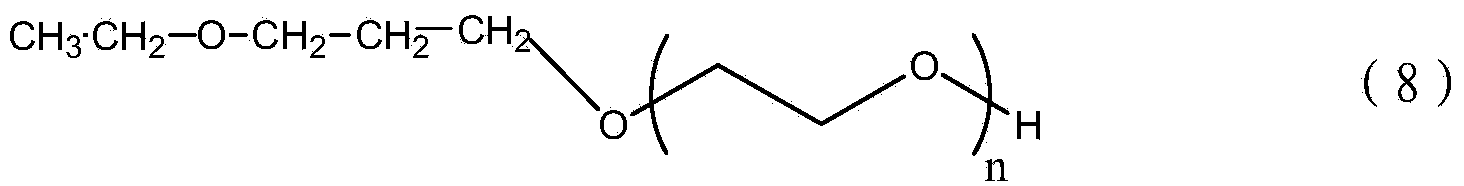

[0068] Preparation of component A: Weigh the viscosity of 2000 centipoise such as structural formula (1), where R 1 for -Vi, R 2 77.89g of double-terminated vinyl polysiloxane (vinyl content 0.2wt%) of -Me, vinyl MDT resin such as molecular formula 2 (viscosity of 500 centipoise, vinyl content 5wt%) 20.0g, add adhesive Such as structural formula (4), n=10, 2.0g, add antistatic agent, such as structural formula (8), n=20, 0.01g, catalyst platinum (0)-2,4,6,8-tetramethyl-2 , 0.1g of 4,6,8-tetravinylcyclotetrasiloxane complex solution, platinum content 10000ppm, sequentially added to the mixer, mixed and stirred evenly to obtain the A component;

[0069] Preparation of component B: Weigh the viscosity of 500 centipoise such as structural formula (1), where R 1 for-Vi, R 2 64.0g of double-terminated vinyl polysiloxane (vinyl content 0.5wt%) of -Me, vinyl MDT resin such as molecular formula 2 (viscosity of 10000 centipoise, vinyl content 0.01wt%) 20.0g, hydrogen-containing polys...

Embodiment 3

[0072] Preparation of component A: Weigh the viscosity of 1000 centipoise such as structural formula (1), where R 1 for-Vi, R 2 62.2g of double-terminated vinyl polysiloxane (vinyl content: 0.3wt%) of -Me, with a viscosity of 2000 centipoise, such as structural formula (1), where R 1 , R 2 15.0g of terminal and side vinyl polysiloxane (vinyl content 8wt%) for -Vi, vinyl MDT resin such as molecular formula 2 (viscosity 5000 centipoise, vinyl content 3.6wt%) 20.0g, add adhesive Agent such as structural formula (5), n=15, 1.0g, add antistatic agent, such as structural formula (7), n=20, 1.2g, catalyst platinum (0)-2,4,6,8-tetramethyl- Add 0.6 g of 2,4,6,8-tetravinylcyclotetrasiloxane complex solution, with a platinum content of 5000 ppm, into the mixer in sequence, mix and stir evenly, and obtain the A component;

[0073] Preparation of component B: Weigh the viscosity of 500 centipoise such as structural formula (1), where R 1 for -Vi, R 2 64.5g of double-terminated vinyl p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com