Granule counting machine

A technology of counting machine and body, applied in the field of counting machine, to achieve the effect of automatic adjustment of front and rear inclination angle, convenient maintenance and convenient layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with the accompanying drawings.

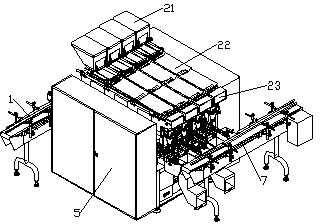

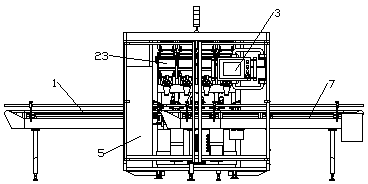

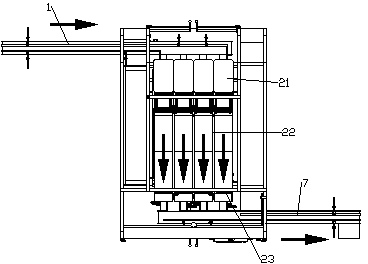

[0051] Such as Figure 1-Figure 6 As shown, the counting machine of the present invention comprises a bottle-in conveyor belt 1, a bottle-out conveyor belt 7 and a counting machine body. On the front side of the machine body. The body of the counting machine includes a granular material channel module group 2 arranged longitudinally at the front and rear, which can complete the vibration conveying of granular materials and perform counting of unloading materials, a channel module group 6 of packaging containers arranged longitudinally at the front and rear, a lower frame 7, an upper frame 8, The electric control box 5 and the touch screen 3, the granular material is illustrated by taking medicine grains as an example, that is, the granular material passage module group 2 is the medicine grain passage module group, and the packaging container passage module grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com