Cheese cutting knife and small diversified dairy product processing device

A processing device and cutting knife technology, applied in dairy products, metal processing, cheese substitutes, etc., can solve the problems of increased cost, inconvenient operation, and low efficiency, and achieve the effects of improving work efficiency, simple structure, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

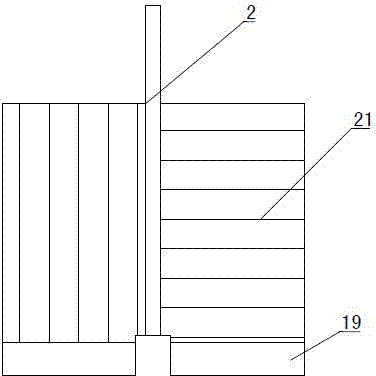

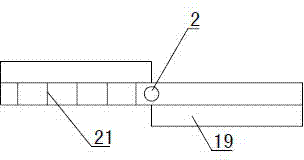

[0027] Figure 1~5 It is the best embodiment of the cheese cutting knife and the small-sized various dairy product processing device of the present invention, below in conjunction with the attached Figure 1~6 The present invention will be further described.

[0028] Refer to attached Figure 1~3 : Cheese cutter, comprising vertical rotating shaft 2, a plurality of cutting blades 21 are fixed on both sides of the rotating shaft 2 to form a rectangular surface, the cutting blades 21 on the left side of the rotating shaft 2 are all vertically arranged, and the cutting blades 21 on the right side of the rotating shaft 2 are arranged vertically. Horizontally arranged, with the rotation of the rotating shaft 2, the cutting blade 21 on the left side cuts the surrounding circular space radially into multiple layers, and the cutting blade 21 on the right side cuts the surrounding circular space axially into multiple layers. Multiple layers, so that the surrounding space is staggered...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com